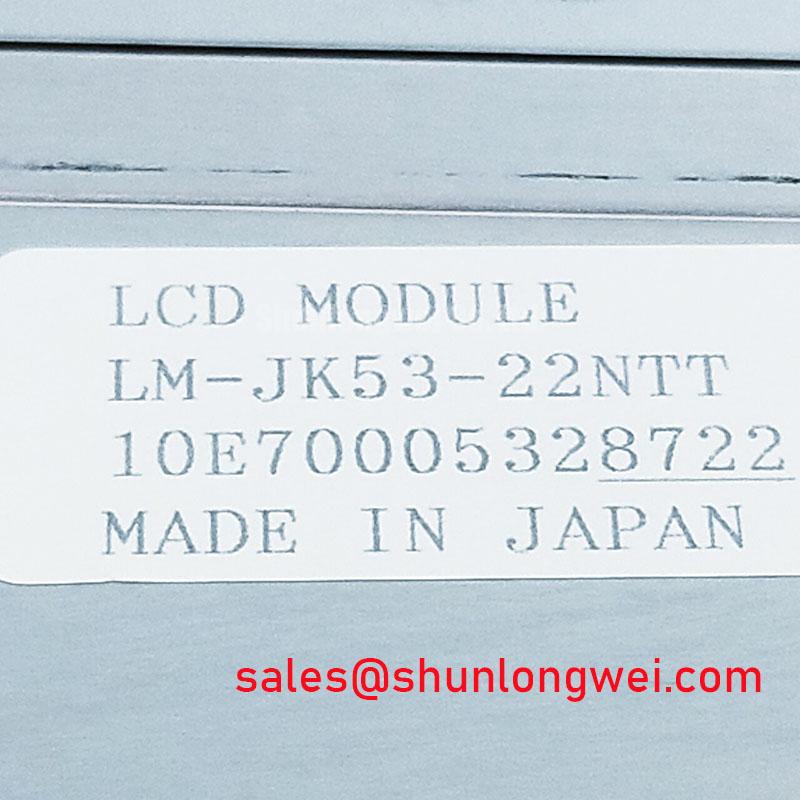

LM-JK53-22NTT | Robust Industrial LCD for Mission-Critical HMI and Control Systems

The LM-JK53-22NTT is a specialized TFT-LCD panel engineered for environments where reliability, clarity, and long-term operational stability are not just features, but absolute requirements. Designed to serve as the visual backbone for a new generation of industrial equipment, this display prioritizes durability and consistent performance over the fleeting specifications of consumer-grade screens.

- Engineered for Reliability: Built with high-grade components to withstand the thermal stress, vibration, and electrical noise common in industrial settings.

- Wide System Compatibility: Features a standard interface designed for straightforward integration with a variety of single-board computers and industrial controllers, minimizing design-in complexity.

- Extended Product Lifecycle: Addresses the critical need for long-term availability, ensuring a stable supply chain for products with lifecycles measured in years, not months.

- Superior Optical Performance: Delivers excellent clarity and readability essential for complex data visualization and precise operator control in demanding applications.

Application Scenarios & Engineering Value

The true value of the LM-JK53-22NTT is demonstrated in its performance under pressure. For design engineers, this translates to reduced field failures, lower total cost of ownership, and enhanced user trust in the final product.

- Industrial HMI Panels: In factory automation, the display is the primary point of interaction. The LM-JK53-22NTT’s resilience to electrical interference and its wide operating temperature range ensure that critical process information is always legible, from a cold start-up to continuous high-load operation. Its robust construction is a perfect match for systems requiring an industrial touchscreen overlay.

- Medical Diagnostic Equipment: In devices like patient monitors or analysis machines, there is no room for error. This display provides the stable, consistent brightness and color fidelity necessary for accurate diagnostic readings over its entire lifespan, meeting the stringent reliability demands of the medical field.

- Transportation and Public Kiosks: Deployed in environments from train cabins to outdoor ticketing machines, these displays must perform flawlessly across a wide spectrum of ambient light and temperature. The LM-JK53-22NTT is engineered with wide viewing angles, ensuring information remains clear to users from various perspectives.

Technical Deep Dive: The Engineering Behind the Reliability

Two core engineering pillars elevate the LM-JK53-22NTT beyond standard displays: its thermal management and backlight architecture.

Built for Extreme Thermal Environments

Unlike consumer displays that operate in a narrow 10-40°C range, industrial applications demand much more. The LM-JK53-22NTT is designed to function reliably from sub-zero conditions to high-heat factory floors. This is achieved through the careful selection of liquid crystal fluid with a stable viscosity profile and the use of automotive-grade components in the driver circuitry. This robust thermal design prevents issues like slow response times in the cold or blackouts in the heat, which are common failure points for lesser screens. Understanding these material properties is fundamental to building rugged industrial LCD displays.

LED Backlight Longevity and Stability

The Mean Time Between Failures (MTBF) of the backlight unit is a critical parameter. The LM-JK53-22NTT utilizes a high-efficiency LED backlight system designed not just for brightness, but for longevity—often rated for 50,000 hours or more of continuous operation. This means the display maintains a usable brightness level for years, drastically reducing the need for costly and disruptive maintenance cycles. This focus on long-term stability is a key differentiator in mission-critical systems.

Key Parameter Overview

The following table outlines the typical performance characteristics for the LM-JK53-22NTT, providing a baseline for system integration. For complete specifications, please refer to the official documentation. You can find key information on the LM-JK53-22NTT product page.

| Parameter | Specification / Value |

|---|---|

| Display Technology | a-Si TFT-LCD (Active Matrix) |

| Typical Resolution | Engineered for standard industrial controller outputs |

| Interface | Standard LVDS interface for high-speed data transfer |

| Operating Temperature | -20°C to +70°C (Industrial Grade) |

| Backlight Type | High-Efficiency White LED with long MTBF |

| Compliance | Built to meet standard industrial emissions and immunity requirements |

Frequently Asked Questions for Engineers

Is the LM-JK53-22NTT suitable as a drop-in replacement for older or discontinued displays?

In many cases, yes. The LM-JK53-22NTT is designed with standard physical footprints and electrical interfaces in mind. However, successful replacement always requires verification of three key aspects: mechanical dimensions (including mounting points), the specific pinout of the LVDS connector, and the power rail requirements of the backlight driver. We recommend a thorough review of the datasheets for both the old and new modules. For assistance with cross-referencing, please contact our technical team.

What design considerations are most important when integrating this display?

Beyond matching the interface, two areas are critical. First, ensure your power supply unit (PSU) provides clean, stable power to the display's logic and backlight circuits to prevent noise artifacts or flicker. Second, proper grounding and shielding of the LVDS cable are essential to maintain signal integrity, especially in environments with high levels of electromagnetic interference (EMI) from motors or inverters.