In the landscape of power electronics, the IGBT module remains a pivotal component. These modules, notably the FZ1200R17HE4 Infineon IGBT Module and the SKD146/16-L100 Semikron IGBT Module, are integral in the advancement of energy efficiency and power density. As global industries accelerate toward electrification and smarter energy management, understanding the nuances between high-performance IGBT modules is essential for purchasing managers, design engineers, and system architects focused on robust, future-ready solutions.

A direct, data-driven IGBT module comparison helps clarify product value:

The contrast lies not only in current and voltage ratings but also in the package, heat dissipation, and the targeted end applications. The FZ1200R17HE4 is engineered for ultra-high power scenarios, such as industrial drives and high-speed railway inverters, featuring enhanced creepage, clearance, and insulation – ideal for high-reliability, harsh environment requirements. On the other hand, the SKD146/16-L100 is tailored for lower- to mid-range industrial equipment, such as DC drives and battery chargers, where thermal demands and form factor take precedence.

The FZ1200R17HE4 impresses with low switching losses and a low VCESAT, translating to higher overall efficiency in dynamic load scenarios. Combined with its copper baseplate and high power density, this IGBT module is well-suited for use in **data center power supplies**, **smart grid switching nodes**, as well as the rapidly growing **electric vehicle (EV) inverter segment**. The global EV market, especially after recent innovations by international leaders such as Infineon and Onsemi, is increasingly shifting to higher current modules that offer robust thermal cycling stability, high overload tolerance, and reliable isolation.

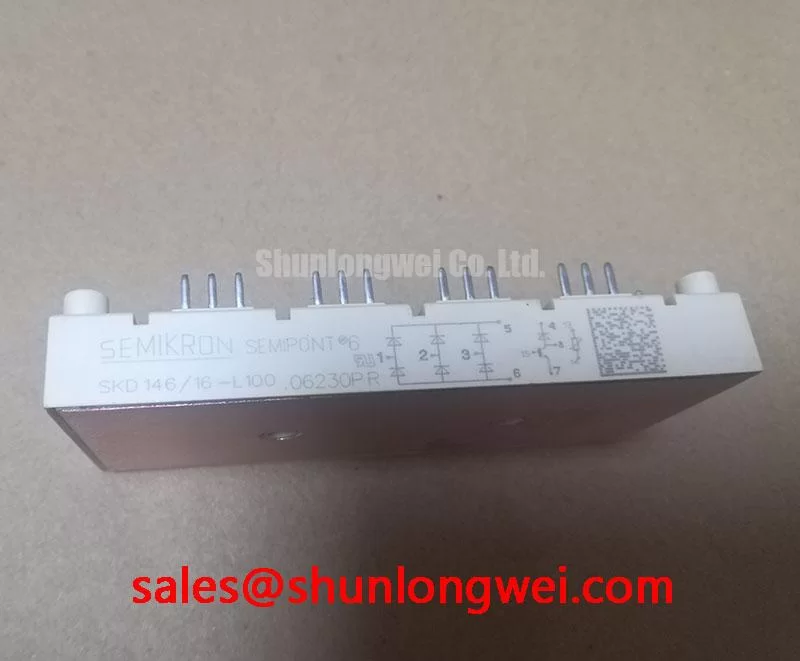

In contrast, the SKD146/16-L100 leverages a DCB ceramic base for isolation and manageable heat transfer, supporting high surge currents in footprint-limited or retrofit scenarios. While its continuous current is notably lower, such modules populate a wide swath of **legacy industrial equipment**, including regulated battery charging stations and field-controlled DC motor drives, where installation flexibility and cost-efficiency are essential.

Choosing between these two modules hinges on more than voltage or current rating; system planners must align technical features with operational priorities. The FZ1200R17HE4 stands out for:

However, it comes with increased complexity in mounting (precise screw torque), higher weight (1300g), and potentially higher cost – not always ideal for compact, cost-sensitive applications.

The SKD146/16-L100 brings value through:

Its limitations center on lower current capacity and moderate power density, making it unsuited for the most demanding converter or traction systems.

Recent years have seen considerable advancement in power semiconductor technology. The surge in adoption of Wide Bandgap (WBG) materials—such as SiC (Silicon Carbide) and GaN (Gallium Nitride)—is pushing the IGBT module market towards higher frequencies, improved efficiency, and miniaturized cooling arrangements. Infineon and STMicroelectronics have lead launches of hybrid modules combining IGBT and SiC elements for energy-intensive quick-charging stations and next-generation industrial pumps.

Notably, with new sectors like **smart grid substations** and **megawatt-scale data centers** requiring reliable, scalable, and low-loss switching devices, modules like the FZ1200R17HE4 remain vital where high current, robust insulation, and durability are non-negotiable. Conversely, Semikron and similar manufacturers are focusing on streamlining the integration process—catering to the retrofit wave across traditional industrial segments and supporting cost-optimized, modular power conversion units.

For further product details and to explore a broad device selection, refer to the Semikron Product Page.

From a product selection perspective, several criteria stand out:

As digital transformation, renewable integration, and electrified transport continue to accelerate worldwide, aligning system requirements with the correct IGBT module is more crucial than ever. Making informed decisions backed by credible parameters and market knowledge matters for achieving maximum operational value and robust lifecycle performance.