Content last revised on November 14, 2025

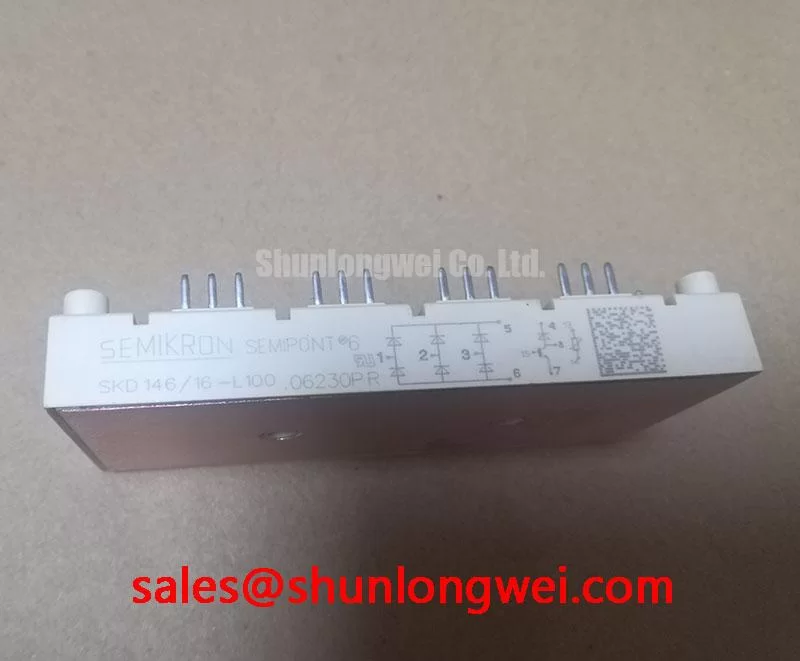

SKD146/16-L100: Reliable 1600V Power Module for Drives

Technical Overview: The SKD146/16-L100 Power Integrated Module

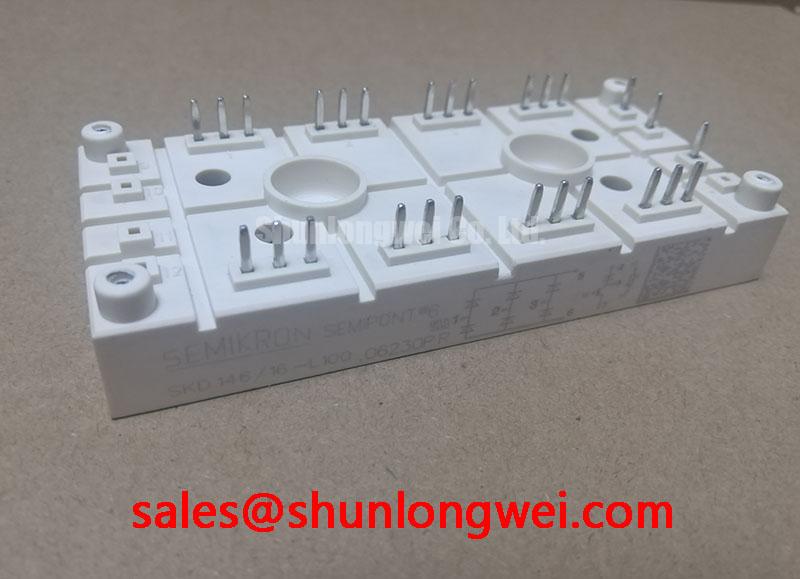

The Semikron SKD146/16-L100 is a SEMIPONT™ 6 series Power Integrated Module (PIM) that delivers robust performance through superior thermal design. It integrates a three-phase input rectifier and an IGBT brake chopper into a single, compact unit. Core specifications include: 1600V | 140A (Rectifier) | Rth(j-s) 0.11 K/W. Key engineering benefits are enhanced operational lifetime and simplified system assembly. This module directly addresses the need for thermal stability in industrial drives by using a Direct Copper Bonded (DCB) ceramic substrate, which establishes an efficient and reliable thermal path to the heatsink, mitigating temperature-induced stress and extending component life.

Answering Your Core Questions on the SKD146/16-L100

This section addresses key technical and application-specific inquiries regarding the SKD146/16-L100 module.

What is the primary advantage of the Direct Copper Bonded (DCB) substrate?

The primary advantage is a significant improvement in both thermal management and electrical isolation. The DCB construction creates a direct, low-resistance path for heat to travel from the semiconductor die to the module's baseplate. This lowers the junction temperature, which is a critical factor for extending the operational life and improving the power cycling capability of the module, especially in applications with frequent start-stop cycles.

How does the SKD146/16-L100's 1600V rating benefit drive designs for 480V or 575V AC lines?

A 1600V repetitive peak reverse voltage (V_RRM) provides a substantial safety margin for drives operating on high-voltage industrial grids like 480V, 575V, or even 690V AC. This high breakdown voltage ensures the rectifier diodes can withstand transient overvoltage spikes common in industrial environments, preventing catastrophic failure and enhancing overall system robustness. It is a key specification for building durable equipment intended for global industrial markets.

What does the 'L100' suffix signify in this part number?

The 'L100' designation typically indicates a specific version of the standard SEMIPONT™ 6 package, often relating to terminal layout or other mechanical details. While the core electrical performance is defined by "SKD146/16," the L100 variant ensures specific mechanical compatibility for certain PCB layouts or bus bar connections, aiding in streamlined assembly for targeted equipment designs.

Is this module suitable for applications with high inrush currents?

Yes. The module specifies a high surge forward current (I_FSM) of 1250 A for a 10 ms duration. This high surge tolerance is critical for applications like motor drives, where the initial charging of DC-link capacitors creates a significant inrush current. This feature ensures the rectifier bridge can survive these repetitive stress events without degradation, contributing to a longer service life. For more on this topic, see our guide to preventing overcurrent, overvoltage, and overtemperature failures.

Deployment Arenas: Where Thermal Stability Drives Performance

The SKD146/16-L100 is engineered for environments where power conversion reliability is directly tied to effective heat dissipation. Its integrated nature and robust thermal design make it a strong candidate for a range of industrial applications.

- Variable Frequency Drives (VFDs): As the front-end rectifier and braking unit for AC motor drives, it provides the core power conversion and regenerative energy handling needed for equipment such as conveyors, pumps, fans, and mixers.

- DC Motor Controllers: The module can serve as a controlled or uncontrolled field rectifier for DC motors, a common requirement in legacy system upgrades and specific industrial machinery.

- Industrial Power Supplies and UPS: In uninterruptible power supplies (UPS) or centralized DC power systems, the SKD146/16-L100 provides a compact and reliable AC-to-DC conversion stage.

- Battery Charging Systems: Its high current and voltage ratings are suitable for building powerful and controlled battery chargers for industrial vehicles or backup power systems.

For AC drives up to approximately 75 kW on 480V-575V lines, the SKD146/16-L100's 140A rating and superior thermal path make it an excellent fit for applications where lifetime reliability is a primary design driver.

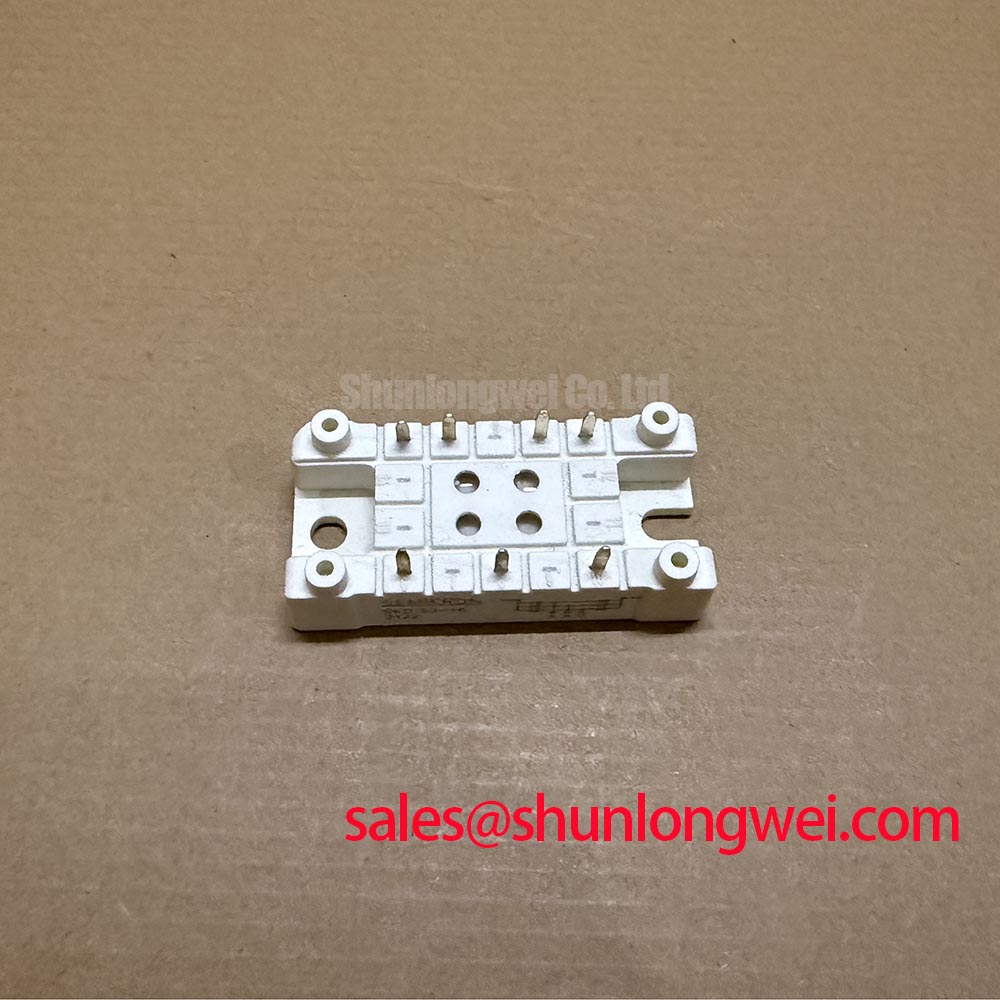

Engineering Footprints: Integrating the SKD146/16-L100

From a system integration perspective, the SKD146/16-L100 offers tangible benefits that simplify the design and manufacturing process. By combining the three-phase input rectifier and the dynamic brake chopper into one industry-standard SEMIPONT™ 6 housing, it immediately reduces the number of components to be sourced, stocked, and mounted. This not only shrinks the required PCB or heatsink area but also minimizes assembly complexity and potential points of failure associated with multiple discrete components and their interconnections. What is the main benefit of the DCB substrate? It provides excellent thermal performance and high electrical isolation.

Inside the Architecture: A Focus on Reliability-Enhancing Features

The SKD146/16-L100 power module's design choices are centered on delivering long-term, stable performance in demanding industrial settings. At its core is the use of a Direct Copper Bonded (DCB) aluminum oxide ceramic substrate. This technology is fundamental to its thermal characteristics. It eliminates the need for a separate, soldered insulating layer, creating a more direct and efficient thermal conduit from the silicon chips to the external heatsink.

The module’s surge current rating of 1250A further underscores its robust nature. This capability ensures it can withstand the electrical stresses of motor startups and line fluctuations without degradation. The high isolation voltage of 3000V (RMS, 1 min) provides a crucial safety barrier, protecting sensitive control circuits and ensuring compliance with stringent industrial safety standards. Together, these features result in a component engineered not just for electrical performance, but for durability and safety throughout its service life.

Core Performance Metrics at a Glance

The following table highlights key parameters from the datasheet for the Semikron SKD146/16-L100. Understanding these values is the first step in a proper design evaluation. For a deeper understanding of how to interpret these figures, consider reviewing a practical guide on decoding datasheets.

| Parameter | Value | Conditions |

|---|---|---|

| Max. Repetitive Peak Reverse Voltage (V_RRM) | 1600 V | Per rectifier diode |

| DC Forward Current (I_D) | 140 A | T_sink = 85 °C |

| Collector-Emitter Voltage (V_CES) | 1200 V | Brake chopper IGBT |

| DC Collector Current (I_C) | 75 A | T_sink = 25 °C, Brake chopper IGBT |

| Surge Forward Current (I_FSM) | 1250 A | t_p = 10 ms |

| Isolation Test Voltage (V_isol) | 3000 V | RMS, 50 Hz, 1 min |

Note: These values are highlights. Please refer to the official SKD146/16-L100 datasheet for complete specifications and operational curves.

The Strategic Value of Robust Power Stages in Modern Automation

In the context of Industry 4.0 and increasing automation, the reliability of a single motor drive can impact an entire production line. The strategic selection of power components, therefore, shifts from pure cost-per-ampere to total cost of ownership (TCO). A module like the SKD146/16-L100, built with thermally efficient and robust technologies like DCB, contributes directly to a lower TCO. By minimizing thermal stress and being resilient to grid anomalies, it reduces the likelihood of premature failures, unplanned downtime, and costly field service interventions. This focus on long-term reliability aligns with the industrial sector's strategic need for dependable, 'set-and-forget' systems that maximize operational uptime and productivity.

Data-Driven Evaluation: SKD146/16-L100 in Context

When evaluating power modules, it is essential to base decisions on technical data. The SKD146/16-L100 provides a highly integrated solution for the input stage of a drive. For systems that require even more robust diode performance, the SKKD162/16 offers a higher current rating in a dedicated dual-diode configuration. However, this would require a separate module for the brake chopper, increasing component count and system complexity. The SKD146/16-L100's value lies in its balanced integration of a 140A rectifier and a 75A chopper, providing a compact, single-package solution optimized for many mid-power industrial drives. What is the benefit of this integration? It reduces component count, assembly time, and potential points of failure.

The strategic choice depends on system architecture priorities. If board space, assembly cost, and a simplified supply chain are paramount, the integrated SKD146/16-L100 presents a compelling case. If the design demands maximum rectifier current density above all else, a discrete or higher-rated module approach might be considered. This data-centric approach empowers engineers to make an informed decision based on the specific constraints and performance targets of their project.