Content last revised on February 1, 2026

SKB72/16 Three-Phase Bridge Rectifier: Engineering Analysis & Datasheet

A Component-Level Look at High-Reliability Power Conversion

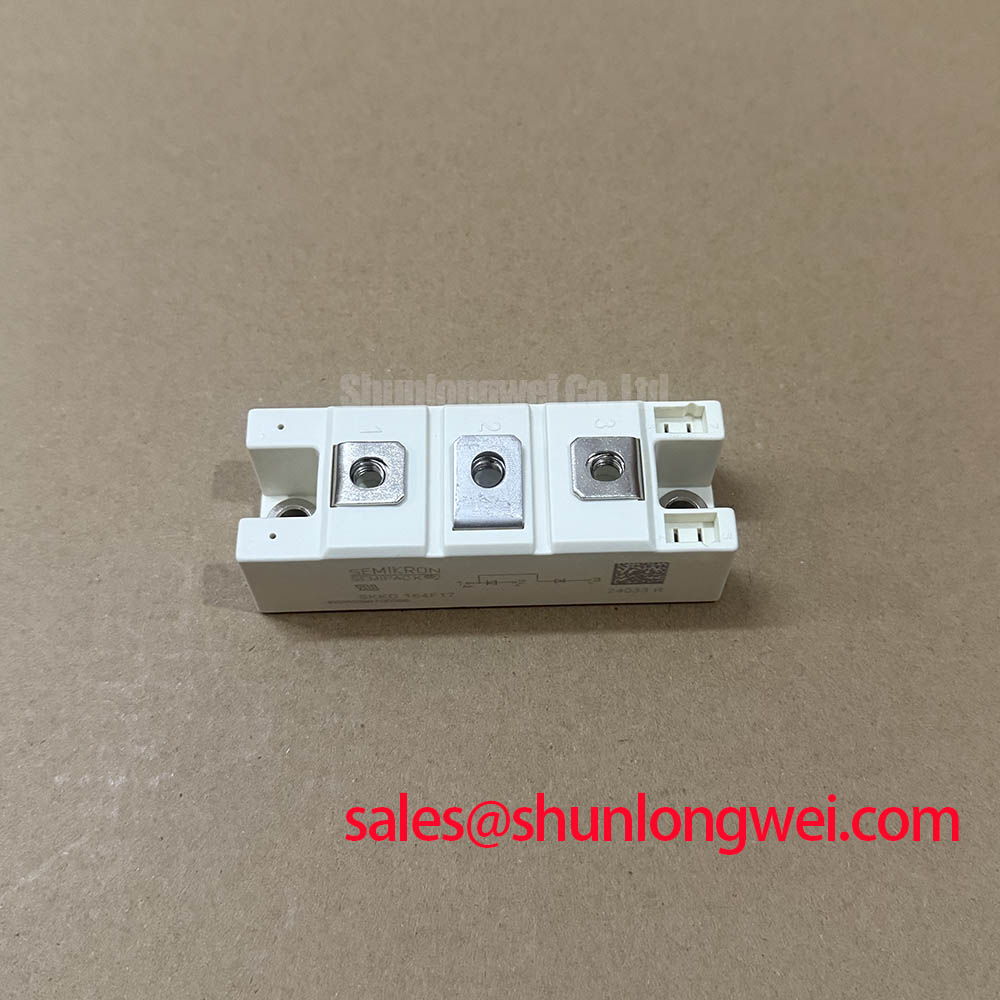

The SKB72/16 by SEMIKRON is a fully controlled three-phase bridge rectifier module engineered for robust performance in demanding industrial power applications. It delivers reliable AC-to-DC conversion through a thermally efficient and mechanically sound package. Key Specifications: 1600V | 75A | 3000V~ Isolation. This module provides two primary engineering benefits: superior thermal transfer and simplified system assembly. It directly addresses the need for a high-voltage rectifier that maintains stable operation, as its maximum forward current capability is directly tied to maintaining a low case temperature, a critical factor for design engineers. For industrial drives operating on 480V or 575V lines, the SKB72/16's 1600V rating provides the necessary safety margin for reliable power rectification.

Key Parameter Overview

Decoding the Specs for Thermal and Electrical Robustness

The technical specifications of the SKB72/16 highlight its suitability for industrial environments. The parameters below are grouped by function to facilitate engineering evaluation for the input stages of power systems. A comprehensive understanding of these values is essential for effective thermal management and ensuring long-term operational reliability.

| Parameter Group | Parameter | Value |

| Electrical Characteristics | Repetitive Peak Reverse Voltage (VRRM) | 1600 V |

| DC Output Current (Id) @ Tc=80°C | 75 A | |

| Surge Forward Current (IFSM) @ Tvj=150°C, 10ms | 750 A | |

| Forward Voltage (VF) @ IF=100A, Tvj=25°C | max. 1.6 V | |

| Thermal Characteristics | Thermal Resistance, Junction to Case (Rth(j-c)) | max. 0.24 K/W per diode |

| Operating Junction Temperature (Tvj) | -40 to +150 °C | |

| Mechanical & Isolation | Isolation Test Voltage (Visol), 50/60 Hz, 1 min. | 3000 V~ |

| Mounting Torque | 5 ± 15% Nm |

Download the SKB72/16 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Industrial Drive and Power Supply Designs

The SKB72/16 is optimally suited for the front-end rectification stage of industrial systems where reliability is paramount. Its primary application is in the input stage of Variable Frequency Drive (VFD) systems, soft starters, and industrial-grade power supplies connected to 380V, 480V, and up to 575V AC lines. In these environments, a key engineering challenge is managing the large inrush currents that occur when equipment is powered on. The SKB72/16's high surge current rating (IFSM) of 750A acts like the robust suspension on a heavy-duty vehicle; it's designed to absorb the sudden, massive jolt of a power-on event without damage, ensuring the stability of the main DC bus and protecting downstream components. This capability is critical for achieving a long operational life in applications with frequent power cycles. For systems that require phase control or regenerative capabilities, a thyristor-based module like the SKKD162/16 may offer additional control flexibility.

Frequently Asked Questions (FAQ)

Engineering Insights into the SKB72/16

What is the primary advantage of the 1600V rating in a 480V system?

The 1600V repetitive peak reverse voltage (VRRM) provides a significant safety margin against transient overvoltages common on industrial power lines. This design choice by SEMIKRON enhances system ruggedness and prevents rectifier failure due to line spikes, which is a critical consideration for designers aiming for high mean time between failures (MTBF).

How does the module's isolated baseplate affect the design process?

The integrated isolated baseplate simplifies the mechanical and thermal design. It allows the module to be mounted directly to a heatsink without the need for additional, thermally resistive isolation pads. This not only reduces assembly complexity and component count but also provides a more efficient and reliable thermal path, which is a core topic explored in guides to unlocking thermal performance.

Is the SKB72/16 suitable for battery charging applications?

Yes, it is well-suited for the uncontrolled rectification stage of high-power battery chargers. Its robust current and voltage ratings can reliably convert AC line power to the raw DC required for the subsequent DC-DC conversion stage that manages the charging profile, making it a staple component in industrial charging infrastructure.

Technical Deep Dive

Analysis of the Thermally-Optimized Package Design

A closer examination of the SKB72/16's construction reveals a focus on thermal efficiency and long-term reliability. The module's design centers on its isolated aluminum baseplate, a key feature that directly impacts system-level thermal management. This construction provides excellent heat transfer from the diode junctions to the heatsink. Think of the baseplate as the foundation of a house built on cool, solid ground—it offers both structural stability and a direct, low-resistance path to dissipate performance-limiting heat. This efficient thermal pathway, characterized by the Rth(j-c) value, allows the module to handle its rated 75A load with a smaller temperature rise, giving engineers more thermal margin or the option to design more compact cooling systems.

Design & Application Support

For engineers integrating the SKB72/16 into a new or existing design, careful consideration of the mounting procedure and thermal interface material is crucial to achieving the specified performance. To maximize reliability and leverage the full capabilities of this rectifier, reviewing the datasheet for thermal derating curves and mechanical mounting guidelines is a recommended next step in your design process.