Content last revised on February 1, 2026

SKD145/16: Technical Specifications, Applications, and Engineering Analysis

A Robust 1600V Three-Phase Bridge Rectifier for Industrial Power Systems

Engineered for High Reliability and Simplified Thermal Management

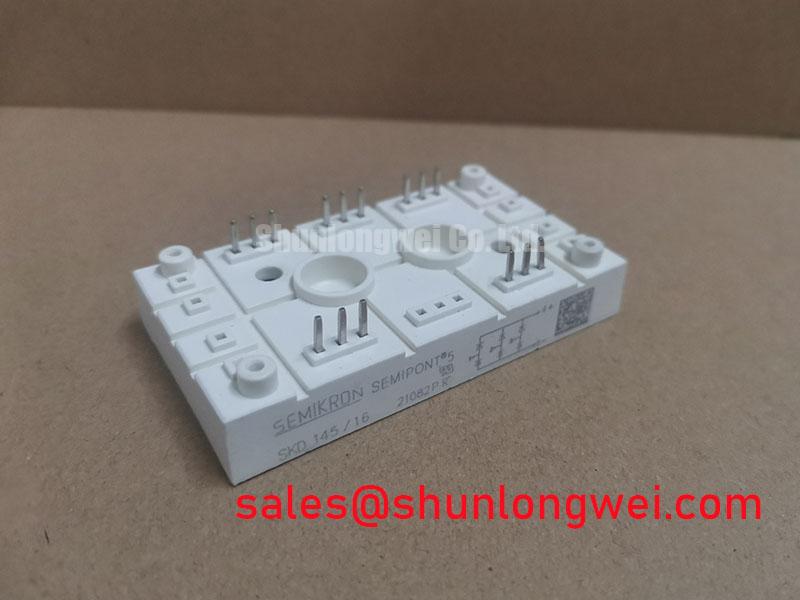

The SKD145/16 by SEMIKRON is a high-performance three-phase uncontrolled bridge rectifier designed for exceptional durability in demanding industrial power conversion applications. With core specifications of 1600V | 142A | Visol 3000V~, this module provides a robust front-end rectification solution. Its key benefits include outstanding long-term reliability due to a hard-soldered design and simplified thermal engineering thanks to its insulated copper baseplate. This component directly addresses the need for a dependable power rectifier capable of operating consistently within the input stages of motor drives and industrial power supplies. For applications requiring robust performance with a considerable safety margin on 480V and 600V AC lines, the SKD145/16's 1600V rating makes it an ideal choice.

Application Scenarios & Value

Delivering System-Level Dependability in Industrial Drive and Power Supply Rectification

The SKD145/16 is fundamentally engineered for the input stages of power conversion systems where reliability is paramount. Its primary role is to convert three-phase AC input into a stable DC voltage, forming the foundation for a reliable DC bus. A high-fidelity engineering scenario is its deployment in the front-end of a Variable Frequency Drive (VFD) controlling a high-inertia industrial motor. During motor startup or under fluctuating load conditions, the power line can experience significant stress. The SKD145/16's robust build and high surge current rating (IFSM = 2000 A) ensure it can withstand these transients without degradation, preventing costly downtime. The high isolation voltage of 3000V simplifies system-level safety compliance and mounting within various industrial enclosures.

This module is optimized for systems including:

- AC Motor Drives and Soft Starters

- Industrial Power Supply Units (PSUs)

- Uninterruptible Power Supply (UPS) Systems

- Battery Charging Systems and DC Power Supplies

What is the main benefit of its construction? The hard-soldered internal connections offer superior resistance to thermal fatigue compared to conventional solder, enhancing the module's operational lifespan. For systems with lower power requirements, the related SKD100/16 provides similar voltage characteristics in a comparable package.

Key Parameter Overview

Decoding the Specifications for a Robust and Thermally Efficient Design

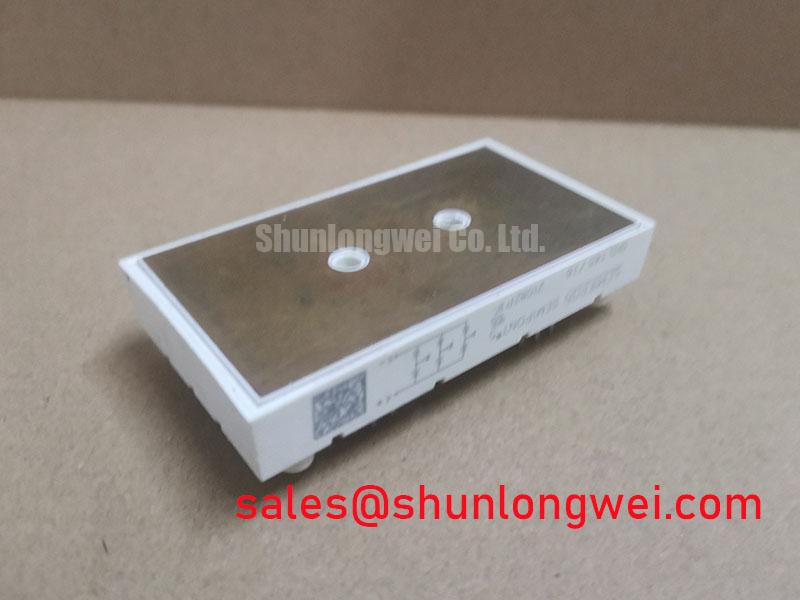

The technical specifications of the SKD145/16 are tailored for robust performance and ease of integration. The parameters below highlight its capacity to handle demanding electrical and thermal loads. Understanding these values is crucial for effective system design and thermal management.

| Parameter | Value | Notes |

|---|---|---|

| Repetitive Peak Reverse Voltage (VRRM) | 1600 V | Provides a significant safety margin for operation on 480V, 575V, and 690V nominal AC lines. |

| DC Output Current (Id) @ Tc = 80 °C | 142 A | Defines the continuous current capability under specified thermal conditions. |

| Surge Forward Current (IFSM) | 2000 A | Crucial for surviving inrush currents during system power-up. |

| I²t Value | 20000 A²s | Essential data for correct fuse selection to protect the module. |

| Threshold Voltage (VT0) | 0.8 V | Component of the forward voltage drop used for calculating conduction losses. |

| Slope Resistance (rt) | 1.7 mΩ | Dynamic resistance component for accurate power loss modeling. |

| Thermal Resistance, Junction to Case (Rth(j-c)) | 0.1 K/W (per diode) | Indicates highly efficient heat transfer from the silicon to the module case. |

| Isolation Voltage (Visol) | 3000 V~ | Ensures high electrical isolation between terminals and the baseplate for safety. |

Download the SKD145/16 datasheet for detailed specifications and performance curves.

Technical Deep Dive

A Closer Look at the Insulated Copper Baseplate Design

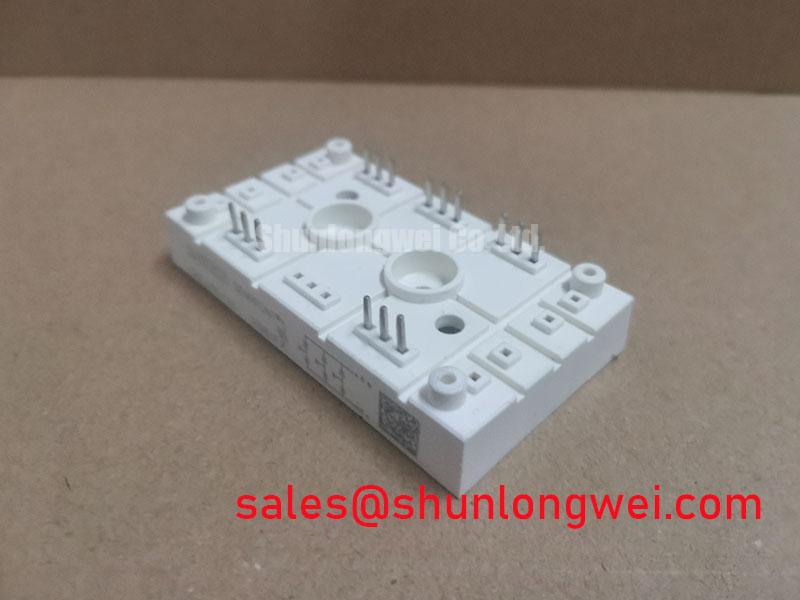

A critical, yet often overlooked, feature of the SKD145/16 is its insulated copper baseplate, a hallmark of the SEMITOP® package design. This construction provides two distinct engineering advantages. First, the high 3000V isolation rating allows the module to be mounted directly to a common, earthed heatsink alongside other components without the need for additional, thermally inefficient insulating pads. This simplifies the mechanical assembly and improves the overall thermal performance of the power stage. Second, the low thermal resistance (Rth(j-c)) of just 0.1 K/W per diode demonstrates the efficiency of the thermal path. Think of it as a wide, unobstructed pipeline allowing heat to flow away from the active silicon junctions with minimal resistance. This efficiency allows engineers to either achieve lower operating temperatures for a given load, thereby increasing system lifetime, or to push more power through the module while staying within thermal limits. This is a crucial element in achieving the high power density required in modern industrial cabinets. For further reading, an engineer's guide to mastering thermal management provides valuable context on these principles.

Frequently Asked Questions (FAQ)

Key Engineering and Integration Inquiries

What is the primary advantage of the glass passivated diode chips used in the SKD145/16?

Glass passivation creates a hermetic seal around the silicon junction, protecting it from moisture and contaminants. This significantly improves long-term stability and reliability, especially in harsh industrial environments where humidity or airborne particles could otherwise lead to premature failure.

How does the 1600V VRRM rating benefit my design?

The 1600V rating provides a substantial safety margin against voltage transients and line surges common on industrial grids. For a 480V AC system (which has a peak line-to-line voltage around 679V), this high VRRM ensures the rectifier operates well within its safe limits, contributing to a more robust and fault-tolerant system design.

Can the SKD145/16 be used for single-phase applications?

Yes, while it is designed as a three-phase bridge, its terminals can be configured for use in single-phase full-bridge rectification. Designers should consult the official datasheet for proper connection diagrams and be mindful of the adjusted current ratings for single-phase operation.

What type of terminal connections does the SKD145/16 use?

The module features screw terminals, which provide a secure and reliable connection method suitable for industrial applications. This ensures low-resistance connections that can handle the rated current without overheating and are resistant to vibration.

From a strategic standpoint, integrating the SKD145/16 into a power system design is a decision in favor of long-term operational integrity. Its robust electrical characteristics and thermally efficient packaging from a reputable manufacturer like SEMIKRON provide the foundational reliability necessary for high-value industrial equipment where service life and uptime are critical business metrics.