Content last revised on January 25, 2026

SKR240/16 Rectifier Diode: Technical Specifications and Engineering Analysis for Power Systems

A High-Reliability 1600V Stud-Mount Diode for Demanding Industrial Applications

The SKR240/16 is a high-current rectifier diode engineered for exceptional operational reliability in harsh industrial power conversion systems. With core specifications of 1600V | 240A | 190°C Tj max, this device provides a robust foundation for building resilient power electronics. Its key benefits include superior environmental resistance and simplified thermal management. This component directly addresses the need for a durable, high-voltage rectifier in uncontrolled rectifiers and line-frequency applications. For high-current DC power supplies operating in harsh conditions, the SKR240/16 is the optimal choice for long-term reliability.

Application Scenarios & Value

System-Level Benefits in Industrial Power Conversion

The SKR240/16 rectifier diode is purpose-built for high-power, line-frequency applications where durability and stable performance are paramount. Its 1600V repetitive peak reverse voltage (VRRM) provides a significant safety margin for systems connected to 400V, 480V, or even 690V industrial AC lines, effectively handling voltage transients without degradation. What is the key benefit of the SKR240/16's hermetic case? It provides maximum reliability in corrosive or humid environments.

A primary engineering challenge in applications like large-scale battery charging systems or the front-end of welding equipment is ensuring continuous operation under heavy electrical and thermal loads. The SKR240/16's high average forward current rating of 240 Amps, achievable at a case temperature of 135°C, is a testament to its efficient thermal design. This allows engineers to design more compact systems by simplifying heatsink requirements, directly impacting the power density and total cost of ownership of the final equipment. While the SKR240/16 excels as a single-device solution, systems requiring a full-bridge configuration may utilize components like the SKKD162/16, which integrates two diodes into a single module.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the SKR240/16 are foundational to its performance in demanding industrial environments. The following table highlights key parameters and interprets their direct engineering value.

| Parameter | Value | Engineering Significance & Value |

|---|---|---|

| Repetitive Peak Reverse Voltage (VRRM) | 1600 V | System Voltage Compatibility: Provides a robust safety margin for direct rectification from high-voltage industrial AC lines (e.g., 690VAC), enhancing system resilience against line voltage fluctuations. |

| Average Forward Current (IFAV) | 240 A (at Tcase = 135 °C) | High Power Throughput: This high current rating at an elevated case temperature signifies excellent heat dissipation, enabling higher power density designs and reducing the dependency on oversized cooling solutions. |

| Max. Junction Temperature (Tj max) | 190 °C | Thermal Headroom: A high maximum operating temperature provides a buffer for transient thermal events, increasing the device's reliability and operational lifespan in environments with fluctuating ambient temperatures. |

| Thermal Resistance, Junction to Case (Rth(j-c)) | 0.16 K/W | Efficient Heat Transfer: This low thermal resistance value is critical. It indicates that heat generated at the silicon junction can be transferred to the heatsink with minimal obstruction, much like a wider pipe allows more water to flow. This directly simplifies Thermal Management . |

| Surge Forward Current (IFSM) | 3500 A (10 ms, 50 Hz) | Fault Condition Robustness: The ability to withstand high, brief current surges is crucial for reliability in applications like motor drives or capacitor charging, where inrush currents are common. |

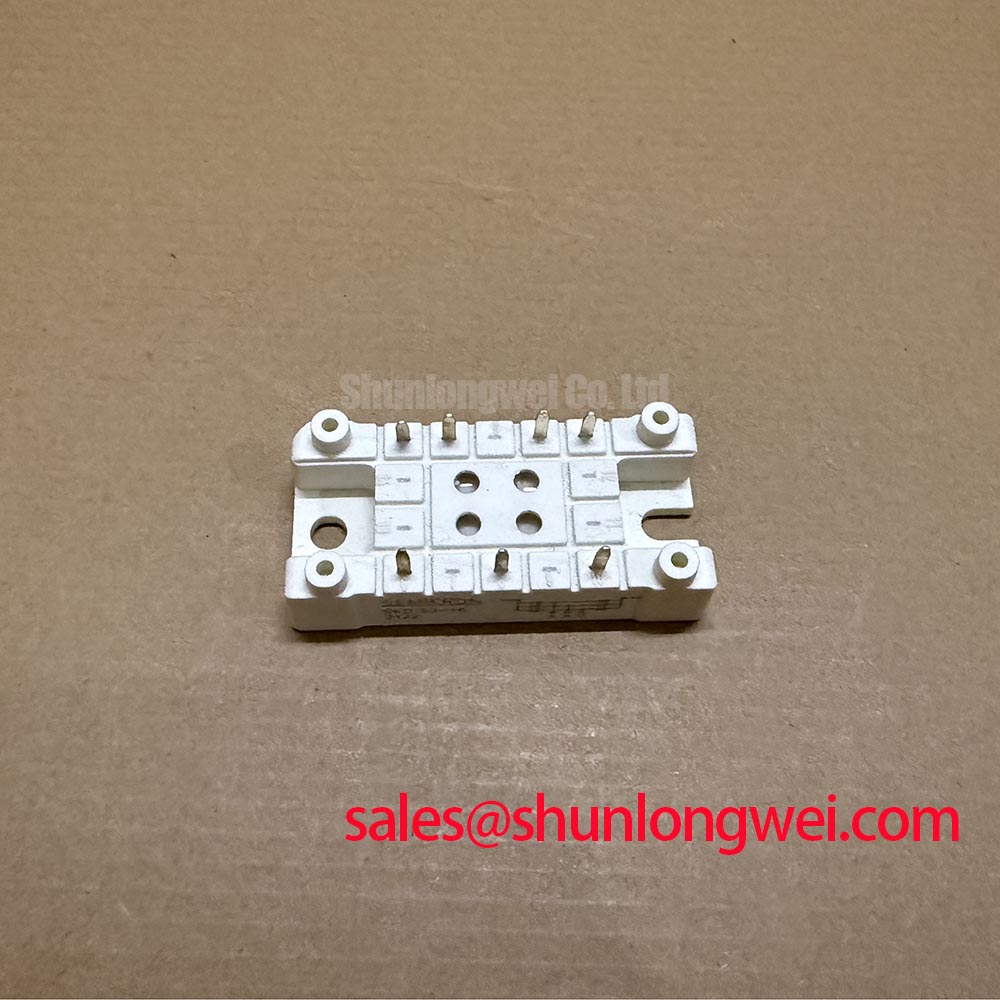

| Mechanical Package | Stud Mount (ISO M24 x 1,5) | Mechanical & Thermal Integrity: Provides a secure, low-resistance path for heat to the heatsink and ensures stable mounting in high-vibration environments such as heavy machinery or industrial generators. |

Download the SKR240/16 datasheet for detailed specifications and performance curves.

Frequently Asked Questions (FAQ)

What is the primary advantage of the SKR240/16's stud-mount design over a module package?

The stud-mount design, also known as a capsule package, provides a direct, low-resistance thermal path from the device case to the heatsink. This often results in superior cooling efficiency and mechanical robustness compared to baseplate modules, making it ideal for single-device installations in high-vibration or physically demanding applications.

How does the 1600V VRRM rating benefit my design for a 480V AC system?

A 480VAC line has a peak voltage of approximately 679V. The 1600V rating provides a safety factor of over 2.3x, which is crucial for accommodating line surges, switching transients, and ringing that can occur in industrial power systems. This ample margin ensures long-term reliability and prevents voltage-induced failures, a key consideration covered by standards from organizations like Infineon.

Is the SKR240/16 suitable for high-frequency switching applications?

No, the SKR240/16 is a standard rectifier diode optimized for line frequencies (50/60 Hz). Its recovery characteristics are not designed for the fast switching required in high-frequency applications like switch-mode power supplies (SMPS) or high-frequency inverters. It excels in applications like front-end uncontrolled rectifiers.

What does the hermetic metal case with a glass insulator imply for system reliability?

This construction provides a true hermetic seal, protecting the internal silicon die from moisture, dust, corrosive gases, and other environmental contaminants. Unlike plastic-encapsulated modules, this design prevents gradual degradation from environmental exposure, making it a superior choice for outdoor equipment, marine applications, or harsh chemical plant environments.

What is a key consideration when mounting the SKR240/16?

Achieving the specified mounting torque is critical. Insufficient torque leads to high Thermal Resistance and overheating, while excessive torque can damage the stud threads or the device itself. Always use a calibrated torque wrench and follow the datasheet's mounting force recommendations to ensure a reliable thermal and mechanical connection.

Technical Deep Dive

Implications of the Hermetically Sealed Stud-Mount Construction

The physical construction of the SKR240/16 is central to its value proposition. The hermetically sealed metal case is not merely a container; it's an engineered barrier against long-term failure mechanisms. In industrial settings, ambient conditions can include high humidity, salt spray in coastal areas, or chemical vapors. These elements can penetrate the micro-pores of standard plastic packages over time, leading to corrosion of internal bond wires and metallization layers, ultimately causing premature failure.

The glass-to-metal seal in the SKR240/16 creates an impermeable barrier, ensuring the internal semiconductor junction remains in a pristine, controlled environment throughout its service life. This is analogous to the difference between a water-resistant watch and a professional dive watch; while one handles splashes, the other is built for sustained pressure and exposure. This level of protection makes the component exceptionally well-suited for mission-critical DC power supplies where maintenance is difficult and reliability is non-negotiable.

An Engineer's Perspective

From a design engineer's viewpoint, the SKR240/16 is a component that prioritizes predictability and robustness over complex features. Its straightforward, high-quality construction instills confidence. The well-defined thermal characteristics and high voltage margin simplify the design process, reducing the need for extensive de-rating or complex protective circuitry. In a landscape often focused on cutting-edge switching speeds, this diode represents the enduring importance of fundamental reliability, providing a steadfast building block for the backbone of industrial power conversion.