Content last revised on January 23, 2026

SKB 60/12: A Robust 1200V, 60A Three-Phase Bridge Rectifier for Industrial Power Systems

Introduction: Engineering Reliability into Your Front-End Power Stage

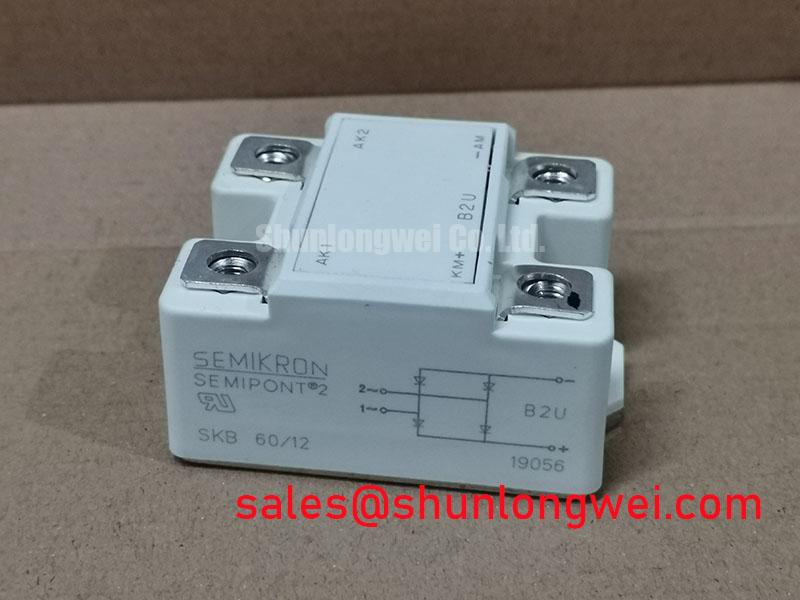

The SKB 60/12 by SEMIKRON is a three-phase power bridge rectifier engineered for high-reliability power conversion in demanding industrial environments. This component delivers robust rectification for AC-to-DC front-ends, combining a high surge current tolerance with a thermally efficient, isolated package to simplify system design and enhance operational longevity. With core specifications of 1200V | 60A | I²t of 5000 A²s, the SKB 60/12 offers substantial design margin for systems connected to 400V and 480V AC lines. Its key benefits include exceptional resilience to inrush currents and simplified, cost-effective thermal management. For industrial drives requiring robust performance against line disturbances and load changes, this 1200V module provides the optimal balance of electrical ruggedness and thermal stability.

Application Scenarios & Value

System-Level Benefits in Industrial Drives and Power Supplies

The SKB 60/12 is engineered to provide a dependable AC-to-DC rectification front-end for a range of industrial applications. Its primary value lies in its ability to maintain stable DC bus voltage under challenging electrical conditions, a critical function in systems like Variable Frequency Drive (VFD)s, DC motor field supplies, and battery chargers.

A high-fidelity engineering scenario is the input stage of a VFD controlling a conveyor belt system. Upon startup, the motor and its associated DC link capacitors create a significant inrush current. The SKB 60/12's high surge current rating (IFSM) of 850A (at Tvj=125°C) is crucial here. This is analogous to a dam's spillway designed to handle a sudden flash flood; the rectifier safely absorbs the massive, short-duration current surge without failing. This robustness prevents nuisance tripping of upstream circuit breakers and ensures reliable system startup, contributing directly to higher machine uptime and productivity. The 1200V repetitive peak reverse voltage (VRRM) provides a substantial safety margin against voltage spikes and transients common on industrial power grids, further safeguarding the entire power converter.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the SKB 60/12 are tailored for reliable, long-term operation. The parameters below highlight its capacity for robust performance and simplified integration into industrial power designs.

| Parameter | Value | Engineering Value & Interpretation |

|---|---|---|

| Repetitive Peak Reverse Voltage (VRRM) | 1200 V | Provides a significant safety margin for rectifying 400/480V AC lines, ensuring the device is not damaged by common voltage transients and line swells. |

| DC Output Current (Id) | 60 A (at Tc = 88°C) | Delivers ample current for mid-power industrial drives and power supplies, with the rating specified at a realistic case temperature. |

| Surge Forward Current (IFSM) | 850 A (10 ms, Tvj=125°C) | Indicates exceptional ruggedness against inrush currents from motor starting or capacitor charging, preventing component failure and enhancing system reliability. |

| I²t Value | 3600 A²s (10 ms, Tvj=125°C) | Crucial for fuse coordination. This high value allows for the selection of downstream protective devices that can clear faults without damaging the rectifier module. |

| Thermal Resistance, Junction to Case (Rth(j-c)) | 0.25 K/W (total) | A low thermal resistance signifies efficient heat transfer from the silicon die to the module's baseplate, simplifying heatsink design and ensuring lower operating junction temperatures for improved reliability. |

| Isolation Voltage (Visol) | 3000 V (1 min) | The integrated isolated baseplate simplifies mounting by allowing direct attachment to a grounded chassis or heatsink without extra insulating materials, reducing assembly time and potential points of failure. |

For a comprehensive understanding of all electrical and thermal characteristics, please Download the SKB 60/12 datasheet for detailed specifications and performance curves.

Technical Deep Dive

Implications of the Isolated Baseplate Design

A standout feature of the SEMIPONT® 2 package is its large, electrically isolated baseplate. This design choice has significant system-level consequences. Traditionally, non-isolated modules require a separate, thermally conductive but electrically insulating pad (like mica or silicone) and specially designed bushings for mounting screws to prevent short circuits to a grounded heatsink. This multi-part assembly introduces complexity, cost, and potential for error. What is the primary benefit of its integrated isolation? Simplified and more reliable thermal design.

The SKB 60/12's design eliminates these extra components. Its 3000V isolation rating allows engineers to mount the module directly onto a grounded heatsink or chassis. This is like an electrician wearing high-grade insulated gloves; the protection is built-in, removing an external variable and potential hazard. This simplification directly translates to faster assembly times and lower bill-of-materials costs. More importantly, it enhances thermal reliability by removing the additional thermal resistance layer of an external insulator, ensuring a more direct and efficient path for heat to escape from the semiconductor junctions.

Frequently Asked Questions (FAQ)

What is the primary advantage of the SKB 60/12's 850A surge current rating?

This high IFSM rating ensures the rectifier can reliably withstand the large inrush currents that occur when charging DC bus capacitors in VFDs or during the startup of DC motors. This prevents premature component failure and increases the overall ruggedness of the power supply front-end.

How does the electrically isolated baseplate simplify the mechanical and thermal design process?

The integrated isolation allows the module to be mounted directly onto a grounded heatsink or chassis without needing separate insulating pads or bushings. This not only reduces assembly time and component count but also provides a more consistent and lower overall thermal resistance path, leading to better cooling and enhanced long-term reliability.

Is the SKB 60/12 suitable for rectifying a 480V AC three-phase line?

Yes. A 480V RMS AC line has a peak voltage of approximately 679V. The 1200V VRRM rating of the SKB 60/12 provides a substantial safety margin, making it well-suited for these applications by ensuring it can handle the nominal peak voltage as well as typical line transients and spikes.

What does the Rth(j-c) of 0.25 K/W signify for system performance?

This value represents the thermal resistance from the semiconductor junction to the module's case. A lower value is better, and 0.25 K/W indicates efficient heat extraction. This allows the module to operate at higher power levels for a given heatsink, or alternatively, enables the use of a smaller, more cost-effective heatsink while maintaining safe operating temperatures, which is critical for power density.

What is the advantage of using a module with screw terminals like the SKB 60/12 in an industrial setting?

Screw terminals provide secure and reliable electrical connections that are resistant to vibration and mechanical stress, which are common in industrial environments. They facilitate easy assembly and maintenance with standard tools, offering a more robust connection compared to solder-based terminals for high-current applications.

An Engineer's Perspective on Integration

From an integration standpoint, the SKB 60/12 is a practical solution for streamlining the front-end of mid-power converters. The combination of its robust electrical characteristics and the mechanically simplified mounting process reduces hidden design costs and potential assembly errors. The generous voltage and surge current ratings allow for the creation of a standardized and resilient AC-DC front-end that can be deployed across multiple platforms operating on different industrial grids. This focus on practical, reliable design makes it a workhorse component for building power systems that are made to last.