Integrated vs. Discrete: Choosing Between IPMs and IGBT Modules for Your Low-to-Medium Power Drive

In the world of modern power electronics, particularly in low-to-medium power motor drives, engineers face a critical design choice that significantly impacts time-to-market, system reliability, and total cost: should you use a highly integrated Intelligent Power Module (IPM) or a more traditional, flexible solution composed of a discrete IGBT module and a separate gate driver? This decision is not merely about component selection; it’s a strategic choice about design philosophy. One path prioritizes development speed and built-in reliability, while the other offers granular control and performance optimization. This article delves into this selection dilemma, providing a practical, field-tested framework for engineers, product managers, and technical decision-makers.

Understanding the Contenders: What Sets IPMs and Discrete IGBTs Apart?

At first glance, both solutions use IGBTs to switch power. However, their level of integration creates two fundamentally different design journeys. Understanding this core difference is the first step in making an informed decision.

The Discrete IGBT Module: A Building Block Approach

A discrete IGBT module is the foundational power switching component. It typically contains a half-bridge, six-pack, or other topology of IGBT dies and their accompanying freewheeling diodes, all co-packaged on a thermally conductive substrate. A classic example is the SKM75GB128D, a robust module that provides the raw power handling capability.

However, this module cannot function alone. It is a powerful but unintelligent switch that relies entirely on external circuitry for control and protection. The design engineer is responsible for creating or selecting:

- A Gate Driver Circuit: This critical circuit amplifies the low-voltage logic signals from the microcontroller (MCU) to the high-current signals required to rapidly charge and discharge the IGBT’s gate capacitance, ensuring efficient switching.

- Protection Mechanisms: This includes designing circuits for over-current (desaturation detection), short-circuit, over-voltage, and under-voltage lockout (UVLO) to protect the expensive IGBT module from catastrophic failure.

- Isolated Power Supplies: The gate driver requires isolated power supplies for both the high-side and low-side IGBTs.

- Feedback Circuitry: Components like temperature sensors and current sensors must be implemented externally.

This approach offers maximum flexibility. Engineers can fine-tune every aspect of the gate drive to optimize for EMI, switching speed, or specific load conditions. For a deeper dive into this area, see these 5 practical tips for robust IGBT gate drive design.

The Intelligent Power Module (IPM): A System-in-a-Package

An Intelligent Power Module (IPM) takes the opposite approach by integrating all these critical external components into a single, compact package. An excellent example is the Fuji Electric 6MBP200RA060. Inside an IPM, you’ll find:

- Power Stages: The core IGBT and freewheeling diode dies.

- Optimized Gate Drivers: High-voltage ICs (HVICs) and low-voltage ICs (LVICs) matched specifically to the IGBTs they are driving.

- Integrated Protection: Built-in and factory-tested circuits for under-voltage lockout (UVLO), short-circuit protection (SCP), and over-temperature (OT) protection.

- Fault Signaling: A dedicated pin that sends a fault signal back to the MCU, simplifying system-level error handling.

This “system-in-a-package” design transforms a complex power stage design into what is essentially a logic-level component. The engineer’s main task is to provide the correct logic signals and manage the thermal interface, drastically simplifying the design process.

Key Takeaways:

The core distinction is simple: a discrete IGBT module is a component requiring significant external system design, offering customization. An IPM is a subsystem that prioritizes integration, reliability, and ease of use, trading some flexibility for a faster, more robust design cycle.

Head-to-Head Comparison: A Multi-Factor Analysis for Drive Applications

To choose the right path, we must compare these two approaches across several key engineering and business metrics. The best choice often depends on which of these factors is the highest priority for your project.

| Factor | Intelligent Power Module (IPM) | Discrete IGBT Module + Driver |

|---|---|---|

| Design Complexity & Time-to-Market | Low. “Plug-and-play” approach drastically reduces design, layout, and testing time. Faster time-to-market. | High. Requires significant expertise in gate drive design, protection circuits, and managing PCB parasitics. Longer development cycle. |

| System Reliability & Protection | Very High. Integrated, factory-optimized protection is closely coupled to the IGBTs, ensuring fast and reliable operation. Reduced component count improves overall system MTBF. | Design Dependent. Reliability hinges on the quality of the external driver and protection layout. More susceptible to noise and layout-induced failures. |

| Performance & Optimization | Good to Excellent. Performance is pre-optimized for a wide range of applications. Limited ability to fine-tune switching characteristics. | Potentially Superior. Offers full control over gate resistance, dead time, and protection thresholds, allowing for maximum optimization for specific efficiency or EMI targets. |

| PCB Footprint & Power Density | Excellent. The high level of integration leads to a much smaller PCB footprint and higher overall power density. | Fair. Requires significantly more board space to accommodate the module, driver IC, isolated supplies, and protection components. |

| Total Cost of Ownership (TCO) | Higher initial component cost, but lower TCO due to reduced R&D, faster assembly, smaller PCB, and fewer components to source and stock. | Lower module cost, but higher TCO when factoring in the cost of all external components, larger PCB, longer development, and potential for costly design revisions. |

Key Takeaways:

The decision matrix reveals a clear trade-off. IPMs provide a shortcut to a reliable and compact design, making them ideal for projects where speed and robustness are paramount. Discrete solutions are the choice for specialized applications where engineers need to extract every last bit of performance and have the resources to manage the associated complexity.

Practical Application Scenarios: Where Does Each Solution Shine?

Theory is useful, but real-world applications are where these differences truly matter. Here are some checklists to guide your decision based on your project’s specific context.

Choose an IPM When… (A Checklist for Engineers)

- ✅ Time-to-market is your #1 priority. You need to get a product to market quickly without a lengthy power stage design and validation phase.

- ✅ Your team has limited power electronics expertise. IPMs abstract away the complexities of gate drive and protection design, reducing risk.

- ✅ Space is at a premium. For applications like compact servo drives, robotics, or integrated motor controllers, the small footprint of an IPM is a major advantage.

- ✅ High reliability is non-negotiable. In applications like commercial HVAC or home appliances, the factory-tested, integrated protection of an IPM provides peace of mind.

- ✅ You are designing a Variable Frequency Drive (VFD) for pumps, fans, or compressors. These applications benefit greatly from the reliability and compact nature of IPMs like the Mitsubishi DIPIPM™ series.

Real-World Example: An engineering team developing a new energy-efficient air conditioning unit was on a tight 9-month schedule. By selecting an IPM like the 6MBP200RA060, they bypassed the 3-4 months typically required for designing and debugging a discrete gate driver circuit. This allowed them to focus on the control algorithm and system integration, successfully meeting their launch date.

Opt for a Discrete IGBT Module When… (A Checklist for Engineers)

- ✅ You need to achieve maximum performance or efficiency. If you’re competing on a fraction of a percent of efficiency, a custom-tuned gate driver for a discrete module is the only way to get there.

- ✅ The application has unique requirements. This could include non-standard DC bus voltages, the need for very specific short-circuit behavior, or the use of advanced SiC gate drivers for ultra-fast switching.

- ✅ You are building a highly modular platform. A discrete design allows the same driver board to be paired with different IGBT modules (e.g., the SKM75GB128D for a 5kW version, and a larger module for a 10kW version), providing platform scalability.

- ✅ Component cost is the absolute primary driver for very high volumes. If you are manufacturing millions of units and have a seasoned power team, the TCO can sometimes favor a highly optimized discrete design.

- ✅ You are designing high-frequency applications like induction heaters or welding power supplies. These require precise control over switching transients that a custom discrete solution can provide.

Real-World Example: A company building high-performance solar inverters needed to maximize energy harvest. By using a discrete IGBT module, their team designed a proprietary gate driver that dynamically adjusted the turn-on/turn-off speed based on load and temperature. This fine-tuning resulted in a 0.8% efficiency gain, a significant differentiator in the competitive solar market. For more on the components that make this possible, explore this in-depth analysis of IGBT modules.

Conclusion: It’s a Game of Trade-offs, Not a Battle of Supremacy

The “IPM vs. Discrete IGBT” debate doesn’t have a single winner. The superior choice is entirely dependent on the strategic priorities of your project. The decision boils down to a fundamental trade-off: do you prioritize **integration, reliability, and speed-to-market (IPM)**, or do you require **ultimate flexibility, performance optimization, and granular control (Discrete IGBT)**?

For a vast number of low-to-medium power drive applications—from industrial automation and robotics to HVAC and home appliances—the benefits offered by modern IPMs present a compelling case. They de-risk the project, shorten the development cycle, and deliver robust, reliable performance in a compact package. However, for specialized, high-performance systems where every nuance of the switching waveform matters, the classic discrete approach remains indispensable. By carefully evaluating your project’s technical requirements, timeline, budget, and in-house expertise against the frameworks provided here, you can confidently make the right choice for your next design. For further consultation on specific modules like the Fuji 6MBP200RA060 or the Semikron SKM75GB128D, feel free to contact our engineering team at Shunlongwei.

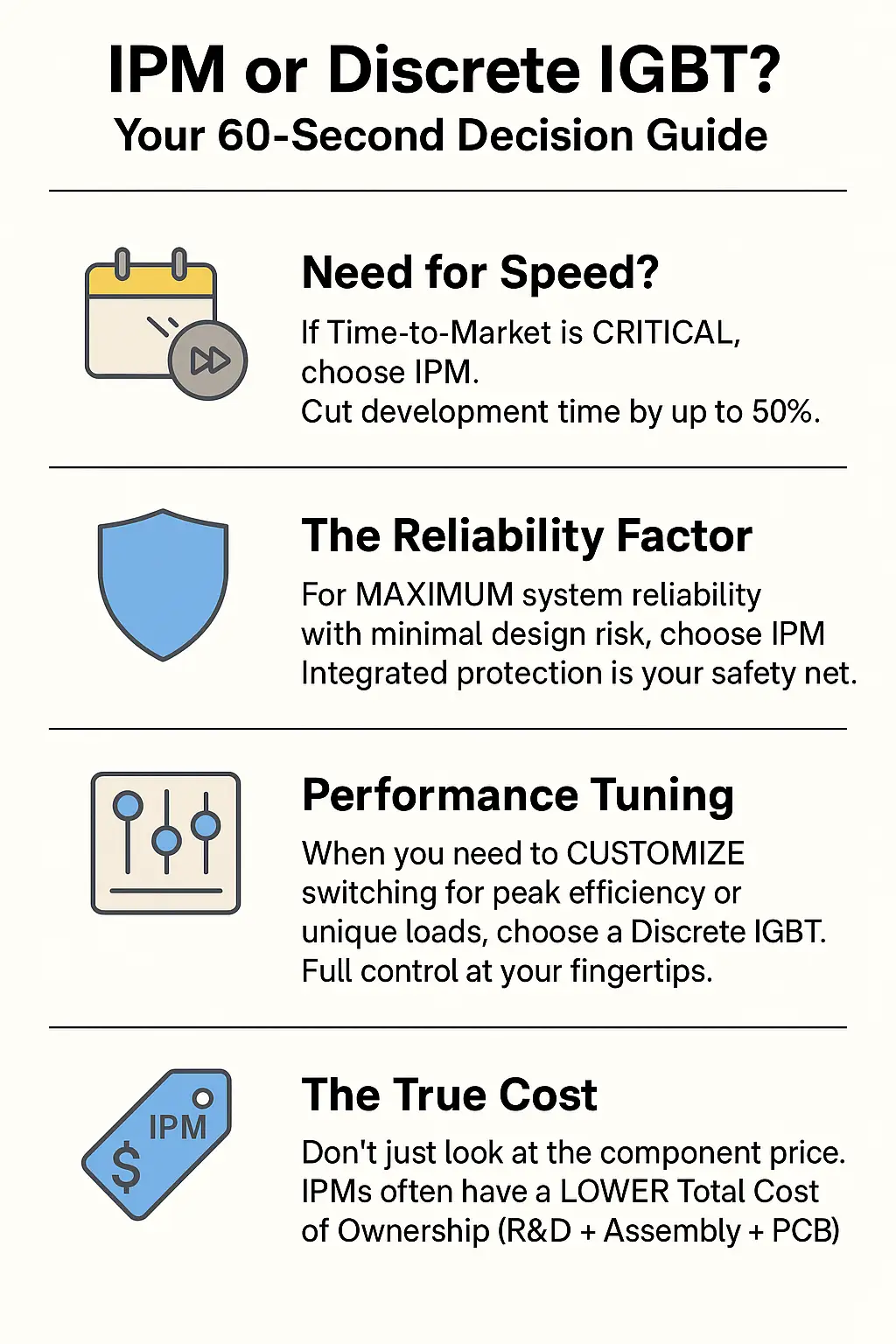

Infographic: IPM vs. Discrete IGBT – A Decision Framework

- Title: IPM or Discrete IGBT? Your 60-Second Decision Guide

- Core Concept: Quickly determine the best power module strategy for your project based on key priorities.

- Key Sections & Visuals:

- Point 1: Need for Speed?

- Content: If Time-to-Market is CRITICAL, choose IPM. Cut development time by up to 50%.

- Visual: A calendar icon with a fast-forward symbol.

- Point 2: The Reliability Factor

- Content: For MAXIMUM system reliability with minimal design risk, choose IPM. Integrated protection is your safety net.

- Visual: A shield icon.

- Point 3: Performance Tuning

- Content: When you need to CUSTOMIZE switching for peak efficiency or unique loads, choose a Discrete IGBT. Full control at your fingertips.

- Visual: A control panel with tuning knobs.

- Point 4: The True Cost

- Content: Don’t just look at the component price. IPMs often have a LOWER Total Cost of Ownership (R&D + Assembly + PCB).

- Visual: A price tag for the discrete module vs. a smaller price tag that includes all associated costs for the IPM.

- Point 1: Need for Speed?

- Branding: Include Logo: Shunlongwei Co., Ltd. | Website: https://www.slw-ele.com