In the realm of industrial electronics design, the display module is rarely just a component; it is the primary interface between the machine and the operator. It dictates the user experience (UX) and often defines the perceived quality of the entire system. However, for procurement managers and project engineers, the choice often boils down to a classic trade-off: the maturity and cost-efficiency of Twisted Nematic (TN) technology versus the superior optical performance of In-Plane Switching (IPS).

This decision is not merely aesthetic. It impacts readability in safety-critical environments, power consumption budgets, and the long-term total cost of ownership (TCO). This guide strips away the marketing jargon to provide a rigorous, engineering-led comparison of TN and IPS technologies, specifically tailored for B2B decision-makers in the industrial sector.

Quick Summary for Decision Makers:

- Choose TN if budget is the primary constraint, the user views the screen from a fixed position, and fast refresh rates are prioritized over color accuracy.

- Choose IPS if the device requires multi-angle readability (e.g., handhelds), accurate color reproduction is necessary, or if “gray scale inversion” poses a safety risk.

1. The Engineering Core: How Pixel Structures Differ

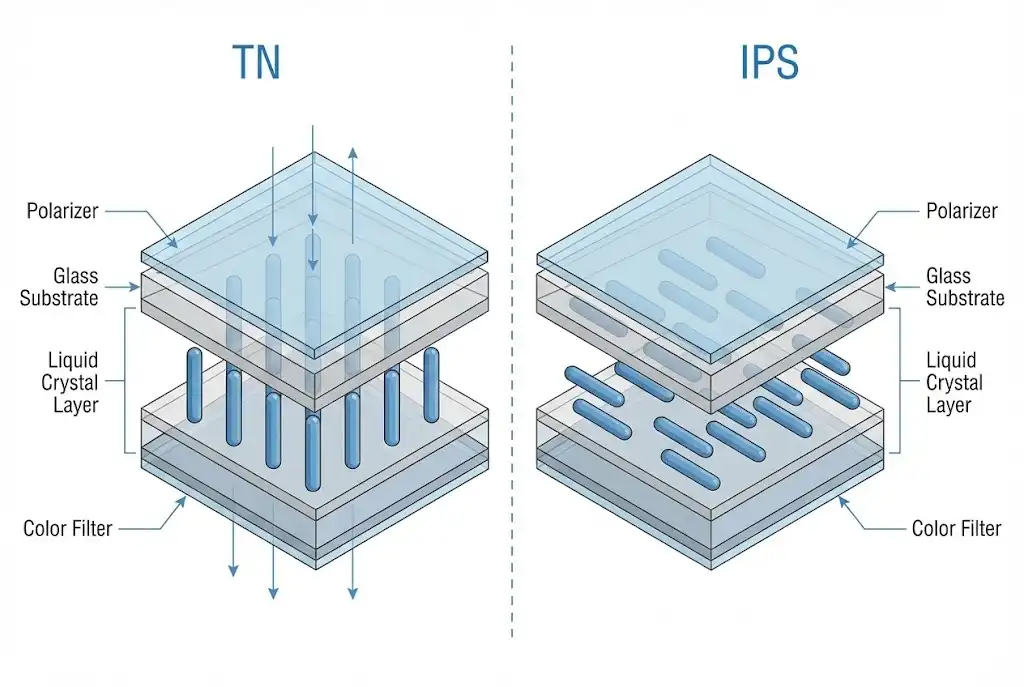

To understand the performance gap, we must first look at the microscopic architecture of the liquid crystal (LC) layer. Both technologies are subsets of TFT-LCD (Thin Film Transistor Liquid Crystal Display), but they manipulate light differently.

Twisted Nematic (TN): The Vertical Helix

TN is the legacy technology that enabled the flat-panel revolution. In a resting state (no voltage), the liquid crystal molecules are arranged in a twisted helix structure, typically rotating 90 degrees between the two glass substrates. This twist guides polarized light through the second filter, allowing it to pass (normally white mode).

When voltage is applied, the molecules untwist and align vertically, perpendicular to the glass substrate. This blocks the light, creating a black pixel. The limitation lies in this vertical alignment: when you view the molecules from an angle, you are looking at the “side” or length of the crystal rather than its cross-section. This results in inconsistent light retardation, causing the notorious viewing angle limitations.

Alt Text: Technical diagram illustrating the vertical alignment of TN liquid crystals versus the horizontal rotation of IPS crystals.

In-Plane Switching (IPS): The Horizontal Rotation

IPS technology was developed specifically to address the shortcomings of TN. In an IPS panel, the liquid crystal molecules are aligned parallel to the glass substrates at all times. Instead of standing up, they rotate within the same plane (hence “In-Plane”) when voltage is applied.

Crucially, both electrodes are located on the same glass substrate (usually the bottom one), creating a horizontal electric field. Because the crystals remain parallel to the screen surface, the light scattering effect is significantly more uniform regardless of the viewer’s position. This optical consistency is why IPS is often described as having “isotropic” viewing characteristics compared to the “anisotropic” nature of TN.

2. Performance Deep Dive: The Data Behind the Decision

For industrial applications, specifications on a datasheet do not always translate linearly to field performance. We break down the critical parameters below.

Viewing Angles and the “Gray Scale Inversion” Phenomenon

This is the single most significant differentiator. A standard TN panel typically offers viewing angles around 45 to 60 degrees horizontally. However, the vertical viewing angle is often asymmetrical. You will often see TN panels specified as “6 o’clock” or “12 o’clock” viewing direction.

The Hidden Risk: Gray Scale Inversion

If an operator looks at a “6 o’clock” TN panel from the 12 o’clock angle (from above), the image doesn’t just fade—it inverts. Dark gray becomes bright, and bright colors become dark. In an industrial context, such as a medical infusion pump or a CNC machine interface, this is critical. If a red “Stop” button appears washed out or inverted due to the operator’s height, it becomes a safety hazard.

IPS panels, conversely, typically maintain color fidelity and contrast up to 178 degrees horizontally and vertically. There is no concept of a “preferred viewing direction” with IPS. This grants the industrial designer immense freedom; the display can be mounted in portrait or landscape orientation without suffering from optical inversion.

For a deeper understanding of LCD fundamentals and how these layers interact, please refer to our guide: The Ultimate Guide to TFT LCD: From Basics to Industrial Applications.

Color Reproduction and Contrast

Because TN molecules align vertically, they allow some light leakage even in the “off” state, resulting in deeper blacks being difficult to achieve. This affects the contrast ratio. Typical industrial TN panels have contrast ratios between 300:1 and 500:1.

IPS panels generally offer contrast ratios of 1000:1 or higher. Furthermore, IPS technology supports a wider color gamut (often approximating sRGB coverage), providing richer and more accurate colors. While accurate color might seem like a consumer requirement (for watching movies), it is relevant in sectors like medical diagnostics where distinguishing between subtle shades of red or blue on a display can affect clinical judgment.

Response Time: The Historical Stronghold of TN

Historically, moving the liquid crystals in-plane (IPS) required more energy and time than simply tilting them (TN). Consequently, TN panels boasted faster response times (often 1ms to 5ms), minimizing “ghosting” in fast-moving images.

However, modern industrial IPS panels have bridged this gap significantly, now achieving response times adequate for almost all HMI (Human-Machine Interface) applications. Unless you are designing a high-speed gaming monitor or specific military optical tracking equipment, the response time difference is negligible for standard GUI interactions.

Alt Text: Comparison showing TN display washing out at an angle while IPS retains color accuracy.

3. Comparative Matrix: TN vs. IPS

The following table synthesizes the technical characteristics to aid in rapid comparison.

| Feature | Twisted Nematic (TN) | In-Plane Switching (IPS) |

|---|---|---|

| Viewing Angle | Limited (~60°). Suffers from Gray Scale Inversion. | Wide (~178°). Consistent from all directions. |

| Contrast Ratio | Low (300:1 – 500:1) | High (800:1 – 1500:1) |

| Color Accuracy | 6-bit (262k colors) typical. Dithering used for higher counts. | 8-bit (16.7M colors) native. High fidelity. |

| Response Time | Fastest (1ms – 5ms). Good for rapid motion. | Moderate (10ms – 25ms). Sufficient for HMI. |

| Power Efficiency | Generally higher light transmittance (requires less backlight). | Lower aperture ratio (requires brighter backlight). |

| Manufacturing Cost | Low (Mature process, fewer mask steps). | Moderate to High (Complex electrode structure). |

| Touch Integration | Sensitive to pressure ripples (“puddling”). | Rigid structure, excellent for touchscreens. |

4. Buying Guide: Scenarios and Recommendations

Choosing between TN and IPS is not about finding the “best” technology, but the “fittest” technology for your specific constraints.

When to Select TN (Twisted Nematic)

Despite the rise of IPS, TN remains a viable engineering choice in specific contexts:

- Budget-Critical High-Volume Projects: For simple metering devices, thermostats, or entry-level appliances where the BOM (Bill of Materials) is scrutinized to the cent, TN offers the lowest entry price.

- Fixed Viewing Positions: If the operator will always be standing directly in front of the machine (e.g., a treadmill console or a strictly positioned ATM), the viewing angle limitations of TN are irrelevant.

- Low-Power, Sunlight Readable Requirements: Because the pixel structure of TN blocks less light than IPS, it has higher transmittance. This means you can achieve higher brightness (nits) with lower LED backlight power, which is beneficial for battery-powered outdoor instrumentation.

When to Select IPS (In-Plane Switching)

IPS is becoming the standard for “Smart Industry” and Industry 4.0 devices due to the superior user experience:

- Handheld and Mobile Devices: For industrial tablets, data collectors, or diagnostic tools that are held in hand and tilted naturally, IPS is mandatory. A TN screen would become unreadable as the user moves their wrist.

- Touchscreen Applications: When you press a finger on a TN screen, the physical displacement of the liquid crystals causes a “puddling” or ripple effect. IPS molecules are aligned horizontally and are structurally more resistant to pressure, making them the superior substrate for PCAP (Projected Capacitive) bonding. Learn more about touch technologies in our Industrial Touchscreen Showdown: RTP vs. PCAP.

- Complex HMIs and Dashboards: Modern HMIs often display complex data visualizations. The color shifts inherent in TN panels can make color-coded graphs misleading. IPS ensures that “Warning Red” looks red from any angle.

Conclusion

The transition from TN to IPS in the industrial market mirrors the shift we have seen in consumer electronics, but with higher stakes regarding reliability and readability. While TN retains a stronghold in cost-sensitive, fixed-view applications, IPS has emerged as the definitive choice for modern, interactive, and high-quality industrial interfaces.

For engineers, the calculation is simple: If the operator’s viewing angle is unpredictable, or if the interface relies on color coding for safety, the premium paid for IPS is an investment in usability and safety. If the application is static and cost-driven, TN remains a robust workhorse.

For trusted, independent reviews on display color standards and calibration techniques relevant to industrial selection, resources like DisplayMate provide excellent technical data to further inform your decision.

Still unsure which panel fits your project’s environmental and optical requirements? Contact our engineering team today for a sample comparison. We can provide side-by-side modules to help you validate the viewing angles and contrast performance in your real-world lighting conditions.