Content last revised on February 2, 2026

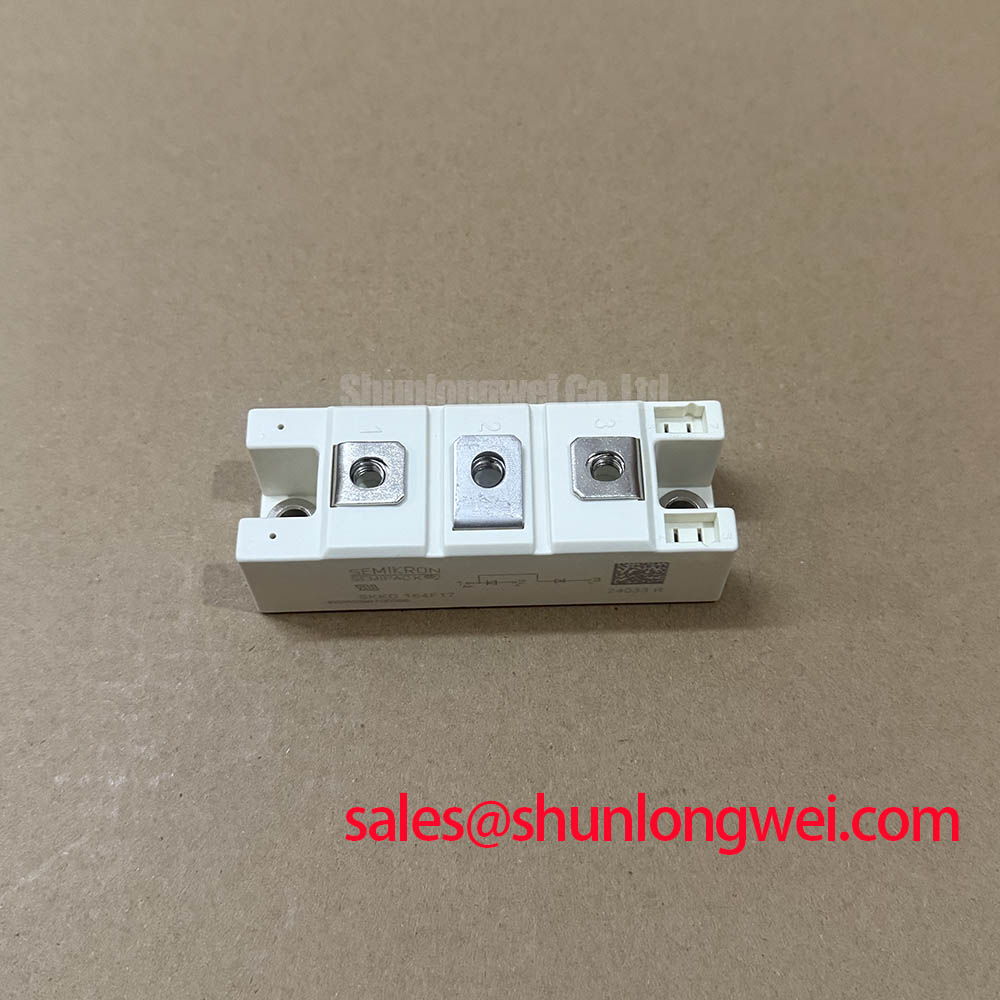

SKD100/16 Three-Phase Diode Bridge Rectifier

Engineering-Grade Insights into the SEMIPONT® 2 Power Module

The SKD100/16 is a three-phase bridge rectifier module engineered for robust performance and long-term reliability in demanding industrial power conversion systems. Its defining value lies in a thermally efficient design that simplifies system integration and ensures operational stability under heavy loads. Key specifications include: 1600V | 100A | 1.15kA IFSM. This module provides two primary engineering benefits: superior thermal management due to its large, isolated baseplate and simplified, secure installation via screw terminals. It directly addresses the challenge of creating compact and reliable input stages for high-power equipment. For industrial drives and power supplies requiring dependable, uncontrolled rectification, the SKD100/16's combination of high blocking voltage and robust thermal design makes it an optimal foundation.

Application Scenarios & Value

System-Level Benefits in Industrial Power Rectification

The SKD100/16 is best suited for the input stages of high-power systems where reliability and thermal stability are critical design criteria. A primary application is in the front-end of Variable Frequency Drives (VFDs), where it provides uncontrolled rectification of the three-phase mains supply. In this scenario, engineers face the challenge of managing significant heat generated during continuous operation while preventing component failure from electrical and mechanical stress. The SKD100/16's large, electrically isolated baseplate is a direct solution, facilitating a low-resistance thermal path to the heatsink. This is analogous to giving a high-performance engine a larger, more effective radiator, allowing it to run at full capacity without overheating. This feature not only improves long-term reliability by keeping junction temperatures in check but also allows for more compact system designs by potentially reducing the required heatsink size. Additional core applications include high-capacity battery charger rectifiers, DC motor field supplies, and general-purpose industrial DC power supplies. For applications requiring controlled rectification, the related SKKD100/16 offers a thyristor/diode configuration within a similar power class.

Key Parameter Overview

Decoding Specifications for Thermal and Electrical Robustness

The technical specifications of the SKD100/16 are tailored for high-reliability industrial applications. The data presented here is crucial for accurate system modeling, thermal design, and ensuring operational safety margins.

| Parameter | Value | Engineering Interpretation |

|---|---|---|

| Repetitive Peak Reverse Voltage (VRRM) | 1600V | Provides a substantial safety margin for operation on 380V, 480V, and even 690V industrial AC lines, protecting the device against common voltage transients. |

| Output Direct Current (ID) | 100A | Specifies the maximum continuous DC current the module can deliver, making it suitable for multi-kilowatt power conversion systems. |

| Forward Surge Current (IFSM) | 1150A (10 ms) | This high surge capability is vital for withstanding the inrush currents typical during the startup of large capacitive loads or motors, preventing immediate failure. |

| Max. Forward Voltage (VF) | 1.35V | A lower forward voltage drop directly translates to reduced conduction losses and less heat generation, contributing to higher overall system efficiency. |

| Operating Temperature Range (Tj) | -40°C to 125°C | The wide operating range confirms the module's suitability for deployment in harsh industrial environments with significant temperature fluctuations. |

Download the SKD100/16 datasheet for detailed specifications and performance curves.

Technical Deep Dive

Anatomy of a Reliable Power Core

The reliability of the SKD100/16 module is not accidental; it is a direct result of its specific construction and material choices. The use of a large, isolated baseplate is central to its design philosophy. This architecture provides excellent electrical isolation, simplifying the mounting process by eliminating the need for separate insulating materials between the module and the heatsink. This integration reduces assembly complexity and potential points of failure. The effectiveness of this isolation is comparable to building a Faraday cage directly into the component's foundation, protecting it from external electrical noise and ensuring system integrity. Furthermore, the robust plastic housing and secure screw terminals are engineered to withstand the mechanical vibration and shock common in industrial settings, ensuring stable and reliable electrical connections throughout the product's operational life.

Frequently Asked Questions

What is the primary benefit of the SKD100/16's large isolated baseplate?

The primary benefit is simplified thermal management and enhanced electrical safety. It allows for direct mounting to a heatsink without additional insulating layers, ensuring a superior thermal interface while providing high dielectric strength for safe operation.

How does the 1600V VRRM rating impact application design?

This high reverse voltage rating provides a significant safety margin for designers, making the module robust enough for direct use in systems connected to 3-phase 480V or 690V industrial grids, where voltage spikes and line fluctuations are common.

Is the SKD100/16 suitable for applications with high inrush currents?

Yes. Its high Forward Surge Current (IFSM) rating of 1.15 kA allows it to safely manage the large, brief inrush currents that occur when powering up systems with large DC link capacitors, such as those found in a Variable Frequency Drive (VFD).

What does the UL recognition (File No. E 63 532) signify for system designers?

The UL recognition indicates that the SKD100/16 has been independently tested and meets established safety standards. This simplifies the process of obtaining final system-level certification for products intended for the North American market, saving development time and costs.

What type of circuit is the SKD100/16 designed for?

It is designed as a B6U (Bridge 6-pulse, Uncontrolled) three-phase full-wave diode bridge rectifier. It is intended for converting three-phase AC input into a DC output without any phase control, making it ideal for the input stage of many power conversion systems.

An Engineer's Perspective on System Integration

From a design standpoint, the SKD100/16 module represents a practical and reliable building block for industrial power electronics. Its straightforward screw-terminal connections and integrated isolation remove common obstacles during assembly, contributing to a more predictable and faster manufacturing process. The robust electrical and thermal headroom simplifies the design of protective circuits and cooling systems, allowing engineers to focus on overall system performance rather than compensating for component limitations. When designing for long-term field reliability, especially in applications like remote pumping stations or manufacturing floor motor drives, selecting a component with a proven architecture like this Semikron module is a sound engineering decision. More insights on component selection can be found in our guide to decoding power module datasheets.