Content last revised on January 20, 2026

SKKR400/0.2-BVR Shunt Module: Data Sheet & Technical Specs

Delivering Stable Current Sensing Through Superior Mechanical and Thermal Design

The Semikron SKKR400/0.2-BVR is a SEMITRANSTM 5 Shunt Module engineered for precise current measurement in high-power systems. This component provides exceptional long-term stability and electrical safety, making it a foundational element for reliable system control. Its design directly addresses the engineering challenge of maintaining measurement accuracy under thermal stress, achieved through an isolated baseplate using Direct Copper Bonding (DCB) technology. This construction ensures a predictable and durable thermal path, safeguarding signal integrity.

- Top Specs: 270A IDCmax | 0.53 mΩ Rshunt | 2500V Visol

- Key Benefits: Excellent long-term stability. Enhanced electrical safety.

Comparative Data for System Evaluation

Evaluating components requires a clear view of their core specifications. The SKKR400/0.2-BVR distinguishes itself through a combination of thermal efficiency and high-isolation characteristics. For engineers assessing current sensing solutions, the following data points are critical for an informed decision. This comparison is offered to support your technical analysis based on verifiable datasheet values. For systems where thermal cycling and voltage withstand are primary concerns, the isolated DCB construction of the SKKR400/0.2-BVR offers a distinct advantage over modules with conventional soldered baseplates.

Application Focus: Where Robustness Drives Performance

The SKKR400/0.2-BVR is specified for applications where operational consistency and safety are paramount. Its design provides tangible benefits in demanding industrial and power conversion environments.

Primary Application: Frequency Converter Current Sensing

In Variable Frequency Drives (VFDs), precise and instantaneous current feedback is essential for motor control algorithms, efficiency optimization, and overcurrent protection. The module's low inductance and excellent long-term stability ensure that the control loop receives an accurate representation of the motor current, free from drift over time and temperature. The robust DCB-isolated baseplate minimizes the risk of failure due to thermal cycling, a common stress factor in drive applications.

Other High-Reliability Scenarios

- Industrial Power Supplies: Provides reliable output current monitoring and protection in high-current DC power systems.

- Welding Equipment: Delivers accurate current feedback for precise control of the welding arc, ensuring consistent weld quality.

- Renewable Energy Systems: Can be utilized in solar inverters and wind turbine converters for monitoring power flow and ensuring system protection. What is the key advantage of its large clearance and creepage distances? They provide a higher margin of safety against electrical arcing in polluted or high-humidity industrial settings.

For high-current industrial drives requiring stable feedback and high electrical isolation, the SKKR400/0.2-BVR's DCB construction provides a superior foundation for system reliability.

Industry Perspective: The Value of Built-in Resilience

In modern power electronics, the trend towards higher power density places significant strain on all system components. The mechanical and thermal integrity of a current shunt is no longer a secondary consideration; it is central to the long-term reliability and total cost of ownership of the end equipment. The SKKR400/0.2-BVR, with its use of DCB technology and substantial electrical clearances, reflects a design philosophy aligned with these industry demands. This focus on intrinsic robustness helps system designers meet increasingly stringent safety standards and deliver products with extended operational lifetimes, reducing the likelihood of field failures and associated maintenance costs. This approach is particularly relevant as automation and electrification expand into harsher operating environments.

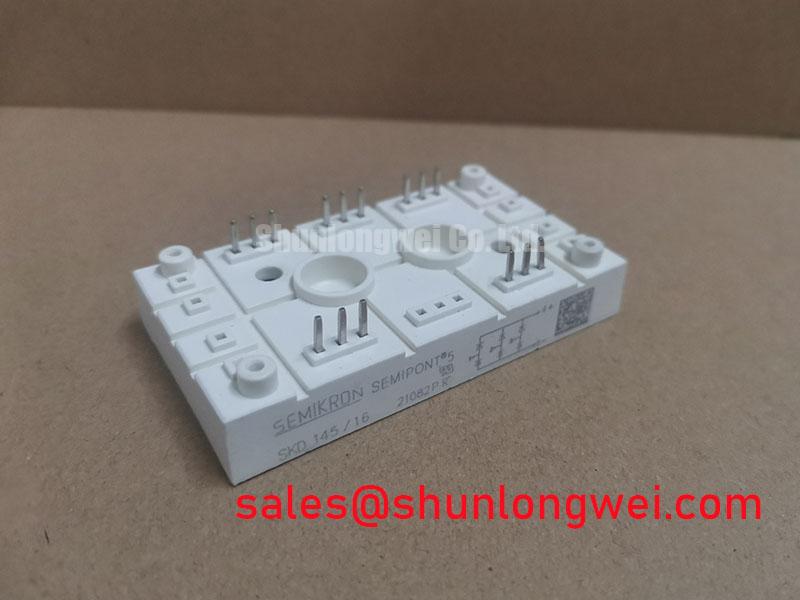

A Closer Look at the Module's Construction

The defining characteristic of the Semikron SKKR400/0.2-BVR is its physical construction, which is purpose-built for electrical and thermal integrity. The core of this is the Isolated Copper Baseplate with Direct Copper Bonding (DCB) Technology. Unlike traditional modules that rely on solder layers, DCB involves firing a ceramic substrate (like Al2O3) with copper sheets bonded directly to both sides. This creates a single, void-free unit with significant advantages:

- Enhanced Thermal Performance: The direct bond eliminates a solder layer, which is often a point of high thermal resistance. This creates a more efficient and reliable path for heat to travel from the shunt elements to the heatsink.

- Superior Mechanical Stability: The thermal expansion coefficient of the ceramic is much closer to that of the silicon shunt elements than a large copper baseplate. This reduces mechanical stress during temperature changes, significantly improving the module's resistance to failure from power cycling.

- High Isolation Voltage: The ceramic layer provides excellent electrical insulation, allowing the baseplate to be safely mounted to a grounded heatsink while the shunt operates at a high potential. The specified 2500V isolation is a direct result of this construction.

Additionally, the module's housing provides large clearance (13 mm) and creepage (20 mm) distances. These carefully defined spatial separations between conductive parts prevent high-voltage arcing, a critical safety feature for compliance with international standards like IEC 60747-1.

Frequently Asked Questions (FAQ)

1. What is the primary benefit of the DCB (Direct Copper Bonding) baseplate in the SKKR400/0.2-BVR?

The primary benefit is enhanced long-term reliability. By eliminating solder layers, DCB technology reduces mechanical stress during thermal cycles and improves heat dissipation, preventing common failure modes associated with solder fatigue and overheating.

2. How does the temperature coefficient of the shunt resistor affect my measurement?

The SKKR400/0.2-BVR has a low temperature coefficient (Tcr) of 50 ppm/K. This is critical for accuracy. It means that for every degree Celsius change in temperature, the resistance value will only change by 0.005%. In a system where operating temperatures fluctuate significantly, this ensures the measured voltage drop across the shunt remains a true and stable representation of the current.

3. Is this module suitable for high-vibration environments?

The module's robust construction, including the solid DCB baseplate and secure screw terminals for both heatsink and electrical connections, makes it inherently resilient to mechanical stress. While specific vibration ratings should be evaluated for the end system, the design is fundamentally more durable than modules relying on less integrated structures.

4. What does the 0.53 mΩ resistance value signify for my design?

This low resistance value is key to minimizing power loss. According to the power formula P = I²R, the heat generated by the shunt is directly proportional to its resistance. A value of 0.53 milliohms ensures that even at high currents (e.g., 270A), the power dissipated as heat is kept to a manageable level (approx. 38.6W), simplifying thermal management.

5. Can I parallel these shunt modules for higher current measurement?

Paralleling shunt modules requires careful consideration of mechanical layout and electrical symmetry to ensure current shares equally. While technically possible, it is critical to consult application notes from the manufacturer, like Semikron, on best practices to avoid measurement inaccuracies or thermal imbalance. For more on module design, explore resources on in-depth analysis of power modules.

Key Technical Specifications

The following table details the critical performance parameters of the SKKR400/0.2-BVR, providing the engineering context for each value. For a comprehensive list of specifications, please download the official datasheet.

| Parameter | Value | Engineering Significance |

|---|---|---|

| Max DC Current (IDCmax) | 270 A (@ Tc=25°C) | Defines the maximum continuous current the module can handle under specified cooling conditions, setting the primary operational limit. |

| Shunt Resistance (Rshunt) | 0.53 mΩ (± 5%) | The core resistance value used to generate a proportional voltage signal for current measurement. Its low value minimizes power loss (I²R). |

| Isolation Voltage (Visol) | 2500 V (AC, 1 min) | Represents the maximum voltage the module's insulation can withstand between the electrical terminals and the baseplate, ensuring safe operation. |

| Thermal Resistance, Shunt to Case (Rth(j-c)) | 7.0 K/W | Indicates the efficiency of heat transfer from the shunt element to the module's baseplate. A lower value signifies better heat dissipation. Think of it as the thermal bottleneck; the smaller the number, the wider the path for heat to escape. |

| Operating Storage Temperature (Tstg) | -40 to +125 °C | Specifies the wide temperature range in which the module can be safely operated and stored, confirming its suitability for harsh industrial environments. |

| Temperature Coefficient (Tcr(shunt)) | 50 ppm/K | Quantifies the stability of the shunt's resistance over temperature. A low ppm/K value is crucial for maintaining measurement accuracy as the system heats up. |

A Note on System Integration

When incorporating the SKKR400/0.2-BVR into a new design, the focus should extend beyond its electrical ratings to its mechanical and thermal interface. Achieving the specified long-term stability is contingent upon proper mounting. Applying the correct torque (3-5 Nm for M6 heatsink screws) ensures optimal thermal contact between the module's baseplate and the heatsink. This minimizes the actual Rth(c-s) (case-to-sink thermal resistance) and allows the module's robust DCB structure to perform as intended. For designs targeting a 10+ year operational life, this mechanical detail is as critical as the electrical specifications. For higher current requirements, devices such as the SKM600GB12M7 may be considered for different segments of the power system.