Content last revised on January 10, 2026

SKBZ28/14: Engineering Data for the 1400V, 28A Three-Phase Rectifier Module

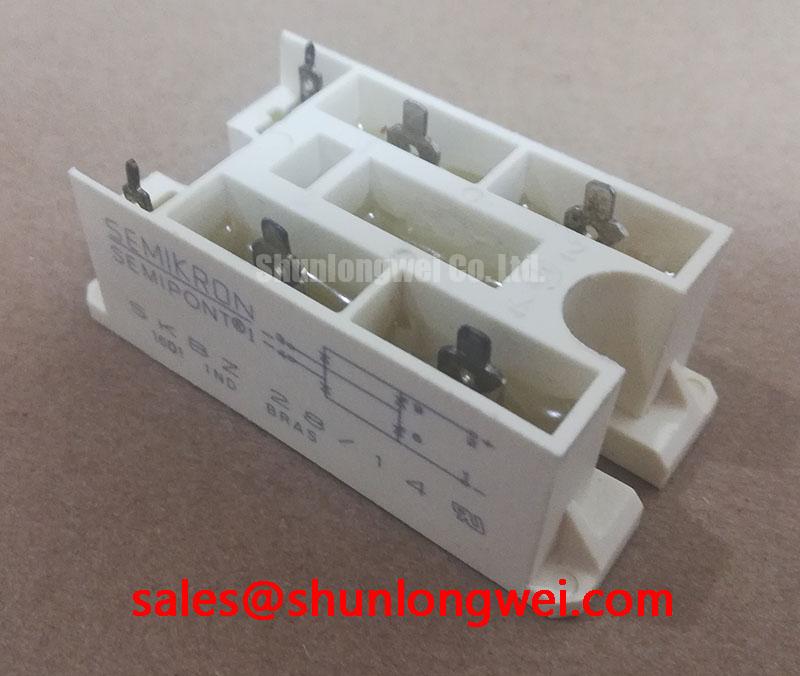

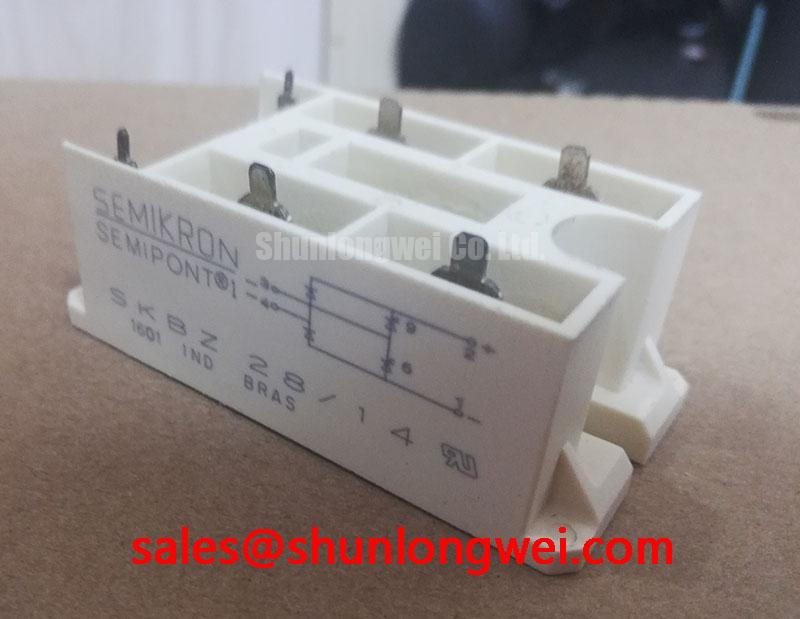

Product Overview for the SEMIPONT® 2 SKBZ28/14

A Foundation for Robust Industrial Power Conversion

The SKBZ28/14 from Semikron is a SEMIPONT® 2 power bridge rectifier module delivering a robust foundation for AC-to-DC power conversion. It combines a high electrical blocking capability with a thermally efficient, easy-to-mount package, streamlining the design of reliable power stages. With core specifications of 1400V | 28A | V_isol 3000V, this module provides two critical engineering benefits: simplified thermal management and enhanced system safety. It directly addresses the need for a durable, non-controlled three-phase rectifier capable of operating on industrial line voltages up to 480V AC. For industrial drive systems that prioritize reliability and simplified assembly, this rectifier module offers a strategically sound front-end solution.

Application Scenarios & Value

System-Level Benefits in Industrial Power Supplies and Drives

The SKBZ28/14 is engineered for core front-end rectification tasks where reliability and manufacturability are primary decision drivers. Its design provides tangible value in applications such as small to mid-sized Variable Frequency Drives (VFDs), industrial Power Supply Units (PSUs), and battery charging systems. What is the primary benefit of its integrated design? It significantly simplifies the power stage by replacing six discrete diodes with a single, fully characterized module.

Consider the design of a compact power supply for a CNC machine operating on a 400V or 480V three-phase line. A key challenge is managing the heat generated by the input rectifier within a constrained enclosure. The SKBZ28/14's isolated baseplate is a decisive feature in this context. It allows the module to be mounted directly to a system chassis or heatsink without needing additional, thermally-inefficient insulating pads. This not only improves the thermal transfer path but also reduces assembly time and component count, directly lowering the total cost of ownership. For applications demanding higher current handling in a similar configuration, the SKKD162/16 offers enhanced power capabilities in a robust module format.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the SKBZ28/14 are tailored for predictable and stable performance in industrial environments. The following table highlights key parameters and interprets their direct engineering value.

| Parameter | Value | Engineering Interpretation & Value |

|---|---|---|

| Repetitive Peak Reverse Voltage (V_RRM) | 1400 V | Provides substantial safety margin for operation on 400V/480V AC lines, protecting the device against common line voltage transients and ensuring long-term reliability. |

| DC Output Current (I_D) | 28 A (at T_c = 100 °C) | Defines the module's continuous current capability under stringent thermal conditions, ensuring dependable power delivery for the target drive and PSU applications. |

| Surge Forward Current (I_FSM) | 500 A (t_p = 10 ms) | This high surge rating indicates robustness against inrush currents during system power-up, preventing premature failure and enhancing the overall ruggedness of the DC Bus. |

| Isolation Voltage (V_isol) | 3000 V (AC, 1 min.) | A critical safety feature. This high isolation rating simplifies compliance with safety standards like IEC 61800-5-1 and provides excellent protection between the power circuit and earthed metalwork. |

| Thermal Resistance, Junction to Case (R_th(j-c)) | <= 1.0 K/W (per diode) | This value is a direct measure of the module's ability to efficiently transfer heat from the silicon die to the case. A lower Rth simplifies Thermal Management , potentially allowing for smaller heatsinks and higher power density. |

Download the SKBZ28/14 datasheet for detailed specifications and performance curves.

Frequently Asked Questions (FAQ)

What is the primary advantage of the SKBZ28/14's isolated baseplate?

The key advantage is simplified assembly and improved thermal performance. It eliminates the need for a separate insulating layer between the module and the heatsink, which reduces bill-of-materials cost, streamlines manufacturing, and creates a more efficient and reliable thermal path for heat dissipation.

Is the 1400V V_RRM sufficient for 480V AC three-phase systems?

Yes. A 480V AC line has a peak voltage of approximately 679V (480 * √2). The 1400V rating provides a safety factor of over 2x, which is a robust design practice that accounts for voltage spikes and line transients typically found in industrial settings, ensuring high reliability.

How do the screw terminals on the SKBZ28/14 benefit an industrial application?

Screw terminals provide a secure and vibration-resistant electrical connection, which is critical in industrial machinery. They facilitate easy and reliable assembly with standard tools and also allow for straightforward field service or replacement, minimizing system downtime.

What does the 500A surge current rating (I_FSM) mean for a power supply designer?

This rating signifies the module's ability to withstand large, brief inrush currents without damage. For a designer, this is crucial assurance that the rectifier can safely handle the initial charging of large DC bus capacitors at startup, a common cause of failure in less robust components.

Can this module be used for single-phase applications?

Yes, while optimized for three-phase systems, the SKBZ28/14 can be configured for single-phase rectification by using two of the three input terminals. This provides flexibility for designers developing a platform of power supplies for different international standards.

Technical Deep Dive

Design Considerations for Reliability and Thermal Efficiency

The architecture of the SKBZ28/14 is fundamentally centered on delivering operational reliability through thoughtful thermal and mechanical design. The use of an Alumina (Al2O3) ceramic Direct Bonded Copper (DBC) substrate is central to its performance. This construction acts as a highly efficient "heat highway," rapidly channeling thermal energy away from the diode junctions to the module's baseplate. This is distinct from designs that rely on less effective insulating materials, which can create thermal bottlenecks and elevate junction temperatures.

Furthermore, the SEMIPONT 2 package itself is engineered for mechanical stability. The robust housing and secure screw terminals are designed to withstand the mechanical stresses and vibrations common in industrial environments. By integrating six diodes into a single, pre-validated package from a trusted manufacturer like Semikron, engineers can bypass the complexities of matching and mounting discrete components, leading to a more predictable and dependable system-level outcome.

An Engineer's Perspective on Integration

From a practical design standpoint, the SKBZ28/14 module is a workhorse component that prioritizes simplicity and robustness over nuanced control. Its value lies not in complex features but in its straightforward, reliable execution of a fundamental task: creating a stable DC bus from a three-phase AC source. When designing systems where long service life and minimal maintenance are non-negotiable, selecting a component with a proven package design and conservative voltage and thermal ratings is a critical first step toward a successful and durable product.