Content last revised on November 21, 2025

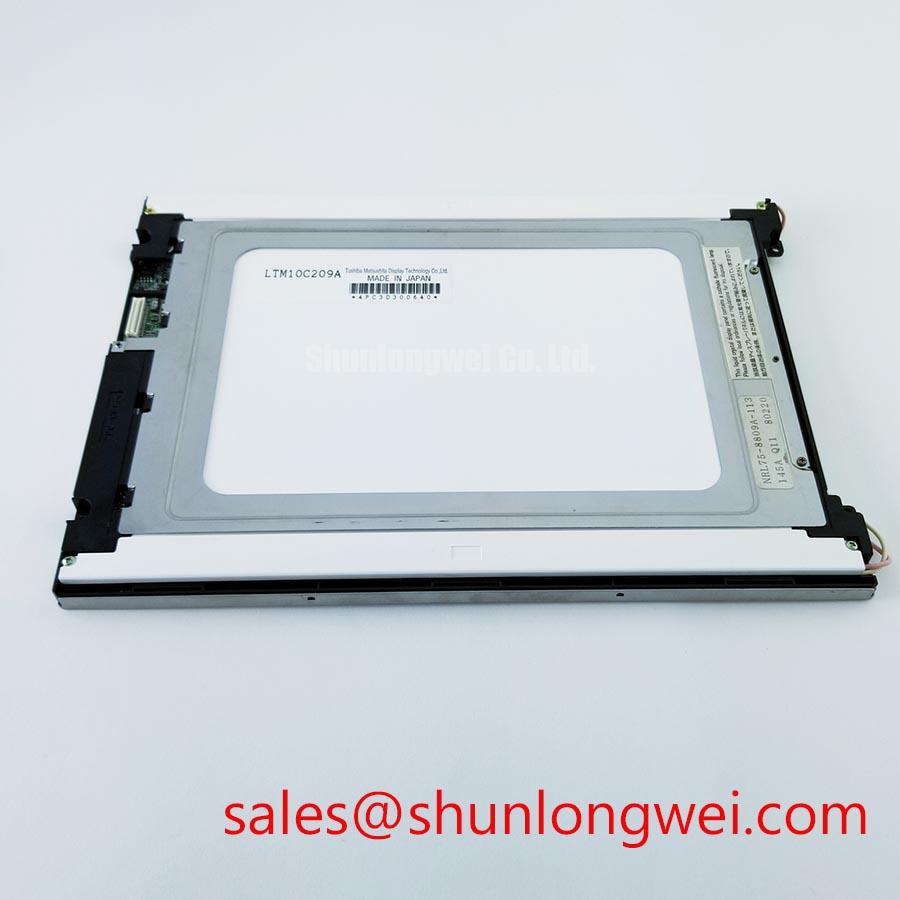

LTM10C209A | 10.4" VGA TFT-LCD for Legacy HMI & Industrial Controls

Product Overview

A Field-Serviceable Display Engineered for Maximum System Uptime

The Toshiba LTM10C209A is a 10.4-inch VGA display engineered for long-term reliability and serviceability in legacy industrial systems. It delivers a precise combination of durability and performance, centered on key specifications of 640x480 VGA | 250 cd/m² | 30,000-Hr CCFL Backlight. The primary engineering benefits are maximized equipment uptime and simplified field maintenance. Its standard TTL interface and physical footprint offer a streamlined path for system repair and life-cycle extension without costly redesigns. For legacy industrial HMIs requiring a durable 10.4" VGA display with field-serviceable backlighting, the LTM10C209A is a benchmark solution.

Key Parameter Overview

Decoding the Specs for Longevity and Seamless Integration

The technical specifications of the LTM10C209A are tailored to meet the demands of industrial environments where reliability and compatibility are paramount. Each parameter underscores its role as a robust component for sustaining legacy systems.

| Parameter | Value & Engineering Significance |

|---|---|

| Panel Technology | 10.4-inch a-Si TFT-LCD: Provides a proven, stable display platform with consistent performance for standard industrial visualization tasks. |

| Resolution | 640 x 480 (VGA): Natively supports the vast installed base of industrial software and control systems designed for this classic resolution, ensuring clear rendering of HMI graphics and text without scaling artifacts. |

| Brightness | 250 cd/m² (Typ.): Delivers sufficient luminance for clear readability in typical indoor industrial settings, such as factory floors and control rooms. |

| Backlight System | CCFL with 30,000-hour typical lifetime & Replaceable Lamp: This is a critical reliability feature. A 30,000-hour lifespan equates to over 3.4 years of 24/7 operation, minimizing downtime. The replaceable design allows for cost-effective field service, extending the asset's life. |

| Interface | 31-pin CMOS (1 ch, 6-bit): Ensures direct, plug-and-play compatibility with a wide range of legacy industrial PCs and controller boards, simplifying repairs and avoiding the need for signal conversion hardware. |

| Operating Temperature | 0°C to +50°C: A standard industrial operating range suitable for deployment in most climate-controlled manufacturing and process control environments. |

Download the LTM10C209A datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Maximizing Uptime in Legacy Industrial Automation Systems

The most significant value of the LTM10C209A lies in its ability to extend the operational life of high-value capital equipment. Consider a CNC machine from the early 2000s with a failed HMI display. The cost of replacing the entire machine or re-engineering its control system is substantial. The LTM10C209A serves as a critical sustaining component in this scenario. Its VGA resolution and standard CMOS interface allow a maintenance engineer to perform a near drop-in replacement, drastically reducing machine downtime and repair costs.

This focus on serviceability is further enhanced by its CCFL backlight system. A common failure point in aging displays is the backlight. With the LTM10C209A, the facility doesn't face a complete panel replacement. Instead, a technician can replace just the lamp unit in the field, a key advantage for managing the Total Cost of Ownership of industrial assets. While the LTM10C209A is ideal for legacy VGA systems, for applications requiring the same 10.4-inch footprint but with higher XGA resolution, designs may utilize panels such as the G104XCE-L01.

Frequently Asked Questions

Engineering Questions on Implementation and Reliability

How does the replaceable CCFL lamp structure benefit long-term system ownership?

It allows for cost-effective field maintenance. Instead of replacing the entire display module—a costly and complex process—technicians can simply swap out the expired CCFL lamp unit. This significantly lowers the total cost of ownership and extends the usable life of the host equipment.

What is the significance of the LTM10C209A's mechanical compatibility with the LTM10C273?

This compatibility provides a simplified replacement or sourcing path for systems originally designed with the LTM10C273 chassis. It means that mounting points and physical dimensions are consistent, allowing engineers to use the LTM10C209A without mechanical redesign, saving significant time and qualification expense.

Is the 31-pin CMOS (TTL) interface on the LTM10C209A suitable for modern system designs?

This display is specifically intended for legacy and sustaining engineering applications where the CMOS/TTL interface is the native standard. For these systems, it offers direct compatibility without the need for LVDS converters. It is not intended for new designs, which typically use LVDS or eDP interfaces.

What does the 250:1 contrast ratio mean for an industrial HMI application?

A 250:1 contrast ratio provides clear differentiation between light and dark states, which is sufficient for displaying typical HMI graphical elements, status indicators, and text in controlled, indoor industrial lighting. It ensures that operators can reliably read critical process information.

What is the primary benefit of its replaceable lamp?

The primary benefit is simplified field service and a lower total cost of ownership by avoiding the replacement of the entire panel.

Technical Deep Dive

A Closer Look at the Design for Long-Term Reliability

The design philosophy of the LTM10C209A is centered on durability and ease of integration into existing frameworks. The choice of a CMOS TTL interface is a key example. For an engineer, this interface is analogous to a USB-A port in a world migrating to USB-C. While newer, faster interfaces exist, the prevalence of controller boards designed with TTL I/O makes this compatibility essential for repair and maintenance. It eliminates the need for an external signal adapter, reducing a potential point of failure and simplifying the system's electronics bill of materials.

Furthermore, the panel's construction using a-Si TFT-LCD (Amorphous Silicon) technology represents a mature and well-understood manufacturing process. This translates to predictable performance and stable electrical characteristics over the panel's lifetime, a crucial factor for industrial applications where performance consistency directly impacts operational safety and quality control.

Industry Insights & Strategic Advantage

The Strategic Role of Sustaining Components in Industrial Asset Management

In today's industrial landscape, extending the life of multi-million dollar machinery is a key strategic priority. The LTM10C209A is more than just a display; it is a strategic tool for asset lifecycle management. For industries like manufacturing and process control, which have long investment cycles, the "rip and replace" model for entire systems is often financially unfeasible. This display enables a more sustainable "repair and maintain" strategy.

By providing a reliable and compatible replacement for aging Human-Machine Interface (HMI) panels, the LTM10C209A helps companies avoid premature decommissioning of otherwise functional equipment. This aligns with a broader industry focus on maximizing return on investment (ROI) and ensuring operational continuity. The availability of such sustaining components is fundamental to the long-term health of the industrial sector, a role also filled by established manufacturers like NEC in the display space. Understanding this ecosystem is part of a deeper dive into TFT-LCD technology and its application.

An Engineer's Perspective

The Right Component for the Right Job

From a maintenance or system engineer's perspective, the LTM10C209A represents a practical solution to a common and costly problem. Its value is not measured by cutting-edge specifications, but by its ability to solve a real-world challenge with minimal friction. The combination of a standard interface, robust backlight, and mechanical compatibility makes it a predictable, reliable, and cost-effective choice for keeping critical legacy systems online. It's an embodiment of the engineering principle of using the right tool for the job, where the job is to ensure continuity and maximize the value of existing assets.