Future of Power Electronics: Market Trends, AI & Next-Gen Technology

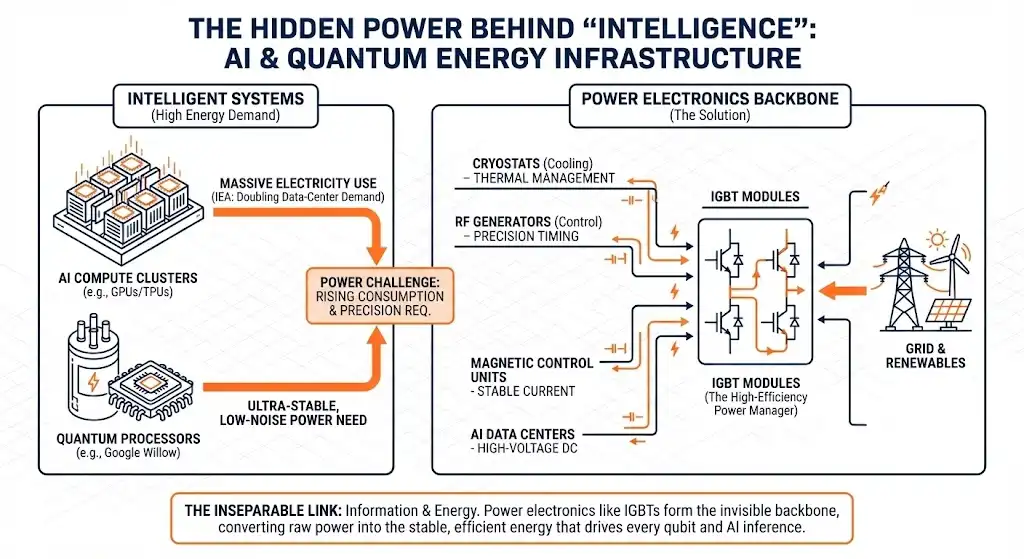

The power electronics landscape is undergoing a fundamental shift. As we approach 2026, the conversation has moved beyond simple efficiency metrics to a more complex challenge: how to manage the exponential power density required by the AI and electrified industrial sectors without compromising reliability.

For decades, the IGBT (Insulated Gate Bipolar Transistor) has been the workhorse of power conversion. However, the rise of gigawatt-scale AI data centers and orbital computing systems is forcing engineers to rethink power topologies. We are no longer just switching current; we are managing a thermal crisis.

The “Thermal Wall” in AI & High-Density Computing

The immediate challenge facing the industry isn’t just generating power, but delivering it to processors that consume upwards of 1000W per socket. As detailed in our analysis of AI and Quantum Computing demands, the power supply unit (PSU) is becoming the bottleneck.

While Wide Bandgap (WBG) materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) are capturing headlines for their high-frequency capabilities, Silicon-based IGBTs remain the economic and robust backbone for high-load applications. In scenarios requiring high short-circuit withstand capability and mature failure modes—such as wind turbines and heavy industrial drives—the IGBT continues to dominate due to its superior cost-per-watt ratio and proven reliability curves.

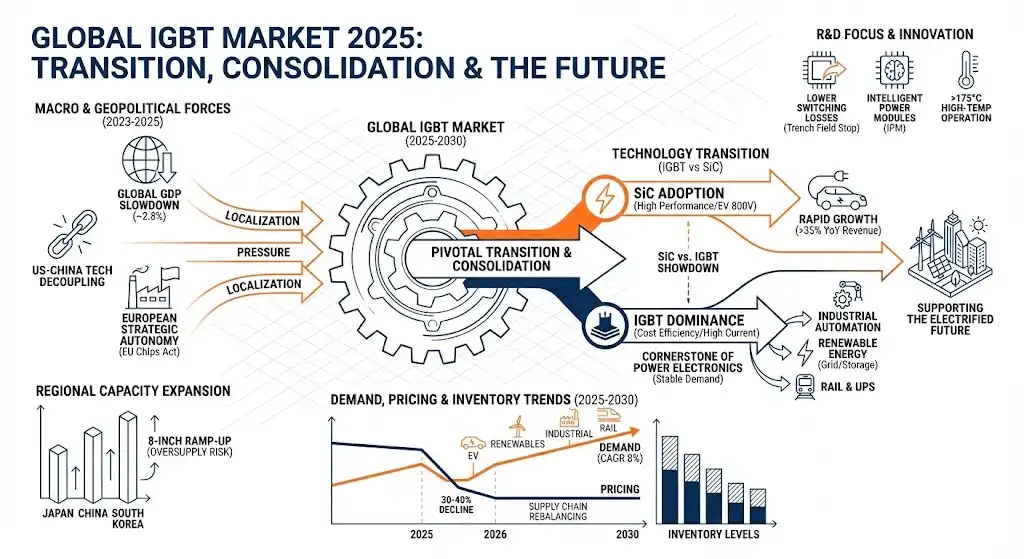

Strategic Outlook: Supply Chain & Technology Coexistence

According to recent industry data (see Yole Group’s market analysis), the global power semiconductor market is entering a stabilization phase. For procurement managers and design engineers, this means 2025-2026 will be defined by “Technology Coexistence”:

- SiC will dominate the 800V EV drivetrain and high-frequency solar inverters.

- IGBT modules (especially IPMs) will retain the market share in industrial automation, rail, and stationary energy storage systems (BESS) where thermal mass and reliability trump pure switching speed.

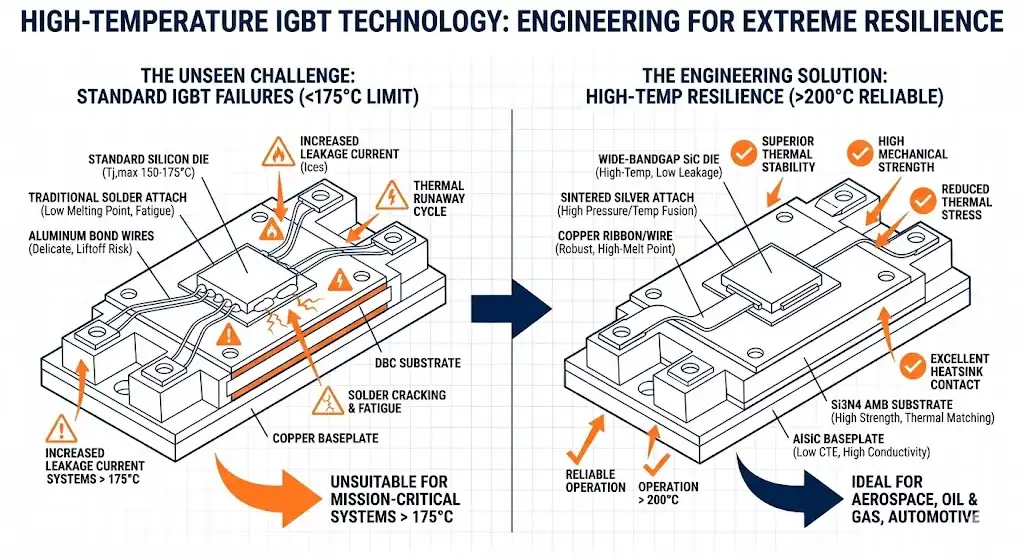

Engineering for Extremes: From Deep Earth to Orbit

Standard datasheets often fail to capture the reality of edge environments. Whether it is a servo drive in a vibration-heavy oil rig or a power module in a satellite constellation (as discussed in our orbital systems report), the failure mechanism is rarely electrical overstress alone—it is usually thermal cycling and package fatigue.

Shunlongwei’s engineering team has curated this resource library to bridge the gap between theoretical specs and field reality. The following articles provide a deep dive into the selection strategies, failure analysis, and future market trajectories for power electronics professionals.