High-Temperature IGBT Technology: Powering Electronics in Extreme Environments

The Unseen Challenge: Why Standard IGBTs Fail in Extreme Heat

In the world of power electronics, the Insulated Gate Bipolar Transistor (IGBT) is a cornerstone of efficiency and control. However, standard silicon-based IGBTs have a critical vulnerability: heat. Most commercial-grade modules are rated for a maximum junction temperature (Tj,max) of 150°C, with some advanced models pushing to 175°C. While this is sufficient for many industrial applications, it represents a hard operational ceiling for systems deployed in environments where “hot” is the baseline. Industries like aerospace, downhole oil and gas exploration, and high-performance automotive applications regularly encounter ambient temperatures that can push power modules beyond their limits.

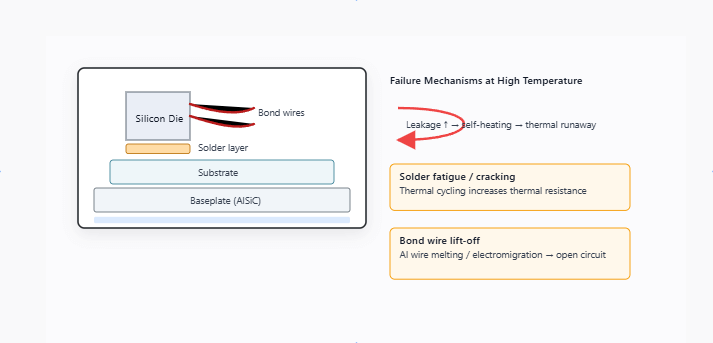

When a standard IGBT operates near or above its Tj,max, a cascade of failure mechanisms is initiated. Increased leakage current (Ices) leads to higher standby power consumption and contributes to thermal runaway—a dangerous cycle where rising temperature causes more current to leak, which in turn generates more heat. Physically, the materials within the module begin to break down. Solder layers, used to attach the silicon die to the substrate, can fatigue and crack under thermal cycling, dramatically increasing the thermal resistance and accelerating overheating. The delicate aluminum bond wires that connect the chip to the module’s terminals can lift off from the silicon surface, causing an open circuit and catastrophic failure. These limitations make standard IGBTs unsuitable for mission-critical systems where reliability is non-negotiable.

The Engineering Behind High-Temperature Resilience

Overcoming the 175°C barrier isn’t just about tweaking a silicon recipe; it requires a holistic re-engineering of the entire IGBT module, from the semiconductor material itself to the packaging that protects it. The goal is to create a device that not only survives but operates reliably and efficiently at temperatures of 200°C and beyond.

Innovations in Semiconductor Materials

The foundation of high-temperature performance lies in the semiconductor material. While incremental improvements in high-purity silicon processing have yielded more robust Si IGBTs, the most significant leap has come from wide-bandgap (WBG) materials, primarily Silicon Carbide (SiC). SiC possesses a bandgap nearly three times wider than silicon, allowing it to operate at much higher temperatures and voltages with significantly lower leakage currents. This inherent material advantage makes SiC the go-to choice for the most demanding high-temperature applications, forming the basis of a new generation of power modules.

Advanced Packaging and Interconnects

A superior chip is useless if its packaging fails. High-temperature IGBT modules employ a suite of advanced packaging technologies designed for thermal and mechanical stability:

-

- Sintered Die Attach: Traditional solder is replaced with sintered silver. This process uses high pressure and temperature to fuse silver nanoparticles, creating a solid, highly conductive bond between the die and the substrate that is far more resistant to thermal fatigue and has a much higher melting point than solder.

–

-

- Advanced Substrates: While Direct Bonded Copper (DBC) is common, high-performance modules often use Silicon Nitride (Si3N4) Active Metal Brazing (AMB) substrates. Si3N4 offers exceptional mechanical strength, high thermal conductivity, and a coefficient of thermal expansion (CTE) that more closely matches silicon, reducing stress during temperature swings.

–

-

- Robust Interconnects: Fine aluminum bond wires are replaced with larger-diameter copper wires or wide copper ribbons. Copper offers better resistance to electromigration and a higher melting point, enhancing the module’s power cycling capability.

–

- Engineered Baseplates: Instead of pure copper, materials like Aluminum Silicon Carbide (AlSiC) are used for baseplates. AlSiC combines high thermal conductivity with a low CTE, ensuring the module remains flat and maintains excellent contact with the heatsink across a wide temperature range. For more detailed insights into thermal performance, understanding why Rth matters is crucial for unlocking an IGBT’s full potential.

Application Deep Dive: Where High-Temperature IGBTs Make a Difference

The development of high-temperature IGBTs is not an academic exercise; it’s a direct response to urgent needs in high-value industries. These modules are enabling technologies, unlocking new levels of performance and reliability.

Aerospace and Defense: More Electric Aircraft (MEA)

Problem: In the push for More Electric Aircraft (MEA), hydraulic and pneumatic systems are being replaced with lighter, more efficient electrical systems. However, power electronics in an aircraft face a hostile environment: high altitudes with thin air (reducing cooling effectiveness), extreme temperature fluctuations from -55°C to over 120°C, and zero tolerance for failure in critical systems like flight control actuators and power distribution units.

Solution: High-temperature IGBTs and SiC modules allow engineers to design power converters that can operate reliably with smaller, lighter cooling systems. By tolerating higher operating temperatures, these modules reduce the dependency on bulky heat pipes, liquid cooling loops, or forced air, directly contributing to weight reduction.

Result: Implementing high-temperature power electronics can reduce the weight of a power conversion system by 10-20%. For a modern airliner, this translates into significant fuel savings over the aircraft’s lifespan and increased payload capacity. The principles share similarities with the robust design required for automotive EV inverters, but with even more stringent reliability demands.

Oil & Gas Exploration: Downhole Drilling and MWD/LWD

Problem: A Measurement While Drilling (MWD) or Logging While Drilling (LWD) tool operates thousands of meters underground, where ambient temperatures can easily exceed 200°C and pressures are immense. These tools rely on sophisticated electronics to power motors, sensors, and telemetry systems. A failure here means pulling the entire drill string out of the borehole—an incredibly expensive and time-consuming operation.

Solution: Custom-designed, hermetically sealed power modules using high-temperature SiC devices are the only viable option. These modules are built to withstand not only the heat but also the intense shock and vibration of drilling. Their high efficiency minimizes internal heat generation, and their ability to operate at extreme temperatures eliminates the need for complex and failure-prone de-rating or cooling systems.

Result: The use of specialized high-temperature modules has been shown to increase the mean time between failures (MTBF) of downhole tools by over 30%. This directly translates to longer, uninterrupted drilling operations, reducing non-productive time and significantly lowering the overall cost of exploration.

Head-to-Head: High-Temperature Si vs. Silicon Carbide (SiC)

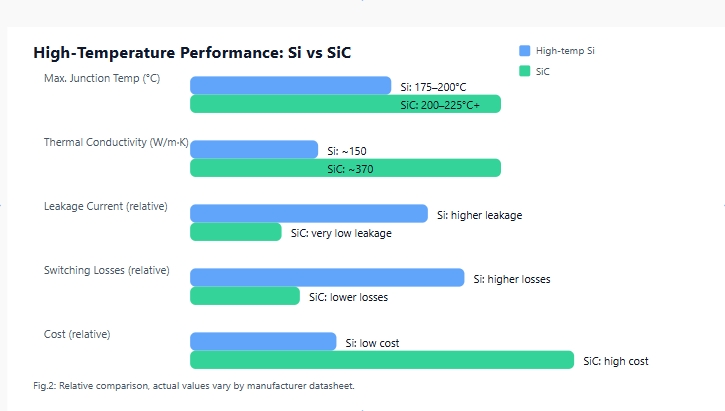

When selecting a high-temperature device, engineers often face a choice between advanced, high-temperature-rated silicon (Si) IGBTs and Silicon Carbide (SiC) MOSFETs or modules. While both represent a step up from standard components, they have distinct performance profiles and cost implications.

| Parameter | High-Temperature Si IGBT | Silicon Carbide (SiC) Module | Engineering Implication |

|---|---|---|---|

| Max. Junction Temp (Tj,max) | 175°C – 200°C | 200°C – 225°C+ | SiC provides a higher operational ceiling, essential for the most extreme environments like downhole drilling. |

| Thermal Conductivity | Good (~150 W/m-K for Si) | Excellent (~370 W/m-K for SiC) | SiC extracts heat from the junction more effectively, leading to a cooler chip under the same load or higher power density. |

| On-state Voltage (Vce(sat) / Rds(on)) | Increases with temperature | More stable with temperature | SiC maintains lower conduction losses at high temperatures, improving overall system efficiency. |

| Switching Losses (Eon, Eoff) | Moderate; increases with temperature | Very low; less temperature-dependent | SiC’s superior switching speed allows for higher frequency operation, reducing the size of magnetic components. |

| Leakage Current (Ices) | Noticeable at high temperatures | Extremely low | Lower leakage in SiC reduces standby power loss and mitigates the risk of thermal runaway. |

| Cost | $$ | $$$$ | Advanced Si offers a cost-effective solution for “hot” applications (e.g., automotive), while SiC is justified for “extreme” applications where performance is paramount. |

Practical Selection and Implementation Guide for Extreme Environments

Designing with high-temperature IGBTs requires more than just dropping a new component onto an old PCB. Success depends on a meticulous approach to selection and system-level design.

Key Datasheet Parameters to Scrutinize

Go beyond the headline voltage and current ratings. For extreme environments, these parameters are critical:

- Tj,max and Power Derating Curves: Don’t just look at the maximum temperature; study how the module’s power handling capability (SOA) derates as temperature increases. Ensure you have sufficient margin. A detailed understanding of common IGBT failure modes can help interpret these curves.

- Rth(j-c) (Junction-to-Case Thermal Resistance): A lower value is always better, indicating more efficient heat transfer from the chip to the module case. Compare this value at different temperatures if the data is available.

- Power Cycling and Thermal Cycling Capability: This indicates the module’s mechanical robustness and lifespan under repeated temperature swings. Look for data provided by reputable manufacturers like in the documentation for Infineon’s .XT technology.

- Short-Circuit Safe Operating Area (SCSOA): Ensure the module can withstand a short-circuit event for a sufficient duration at your maximum operating temperature, as withstand time decreases significantly with heat.

Design Considerations Beyond the Module

The IGBT is only one part of the system. To ensure its reliability, the surrounding components must also be up to the task.

- Gate Driver Selection: Use a gate driver specifically rated for high-temperature operation. The driver must provide a stable, clean gate signal across the entire temperature range and have robust protection features like Undervoltage Lockout (UVLO).

- Thermal Interface Material (TIM): The TIM between the module baseplate and the heatsink is a common point of failure. Use high-performance, high-temperature rated TIMs that resist pump-out and degradation over time.

- PCB Layout and Busbars: At high temperatures and fast switching speeds, minimizing parasitic inductance is critical to prevent voltage overshoots. Use laminated busbars and careful PCB layout techniques. High-power modules like the FZ1200R33KF2C require particular attention to layout to manage their performance.

The Future Horizon: What’s Next for Extreme Environment Power Electronics?

The drive for power electronics that can withstand ever-harsher conditions is relentless. Looking ahead to 2025 and beyond, we can expect several key trends to mature. The integration of gate drivers, temperature sensors, and current sensors directly into the power module will become more common, creating intelligent, self-protecting systems. While SiC currently dominates the high-power, high-temperature space, Gallium Nitride (GaN) technology will continue to mature, offering compelling solutions for lower-power, higher-frequency applications in extreme environments.

Furthermore, packaging technology will continue to evolve, with developments in double-sided cooling, embedded die technologies, and new materials pushing power density and reliability to levels that are difficult to imagine today. These advancements will be crucial for next-generation electric aircraft, deeper and hotter oil wells, and more efficient and durable electric vehicles.

Conclusion: Embracing the Heat for Unprecedented Innovation

High-temperature IGBT technology is far more than an incremental improvement. It is a fundamental enabler that dismantles the thermal barriers holding back progress in some of the world’s most critical and demanding industries. By combining advanced semiconductor materials like SiC with revolutionary packaging techniques, these modules offer a path to creating power systems that are smaller, lighter, more efficient, and dramatically more reliable in the face of extreme heat.

For engineers and procurement managers grappling with thermal management challenges, the solution may not be a bigger heatsink, but a better IGBT. Investing in a robust, high-temperature module, such as specialized components like the SKM400GAL176D, can simplify system design, reduce lifecycle costs, and unlock performance previously thought impossible. If your application operates where others fail, it’s time to explore the power of high-temperature technology. Contact the experts at SLW-ELE to find the right components for your extreme environment challenge.