Content last revised on January 17, 2026

Semikron SKiiP 25AC126V1 | High-Reliability CIB Module for Compact Motor Drives

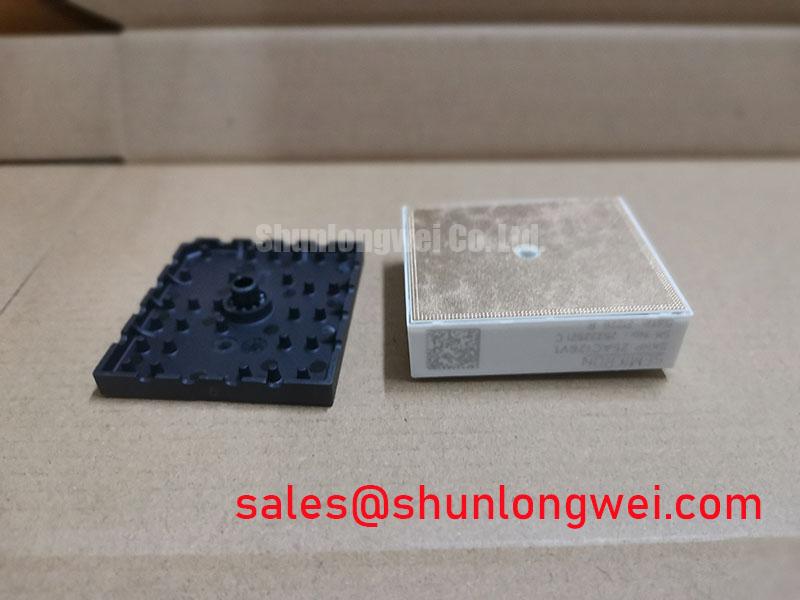

The Semikron SKiiP 25AC126V1 is not just another power module; it's a fully integrated power system engineered for applications where reliability and power density are non-negotiable. By combining a three-phase rectifier, a brake chopper, and a three-phase inverter into a single, compact package, this Converter-Inverter-Brake (CIB) module drastically simplifies the design of sophisticated motor control systems. It is the definitive choice for engineers developing next-generation, space-constrained industrial drives.

- Complete Power Stage Integration: Features a CIB topology that consolidates the entire front-end and inverter stage, reducing component count, minimizing PCB footprint, and accelerating time-to-market for servo drive and VFD applications.

- Unmatched Mechanical & Thermal Reliability: Built on Semikron's renowned SKiiP® Technology, which utilizes a solder-free pressure contact system. This eliminates the primary failure mechanism of solder fatigue, delivering superior power and thermal cycling capabilities.

- Intelligent and Protected Operation: Comes equipped with an integrated gate driver board featuring comprehensive protection against under-voltage (UVLO), over-current, and over-temperature. A built-in temperature sensor provides direct feedback for robust system management.

- Optimized Switching Performance: Employs advanced Trench Field Stop IGBT4 and CAL 4 (Controlled Axial Lifetime) freewheeling diodes, achieving an excellent balance between low conduction losses (VCE(sat)) and reduced switching energy.

Technical Deep Dive: The SKiiP Advantage

The core innovation of the SKiiP 25AC126V1 lies in its construction. Unlike conventional IGBT modules that rely on soldered connections between the DBC substrate and the baseplate, SKiiP technology uses a precisely calibrated pressure system. This engineering choice directly addresses the issue of solder fatigue caused by mismatched Coefficients of Thermal Expansion (CTE) during thermal cycles. The result is a module with a significantly longer operational life and exceptional resilience in environments with high vibration or frequent temperature swings. This makes it an ideal component for mission-critical industrial automation.

Application Scenarios & Engineering Value

The highly integrated nature of the SKiiP 25AC126V1 provides tangible benefits across several demanding applications:

- Compact Variable Frequency Drives (VFDs): The CIB topology is a game-changer for VFD design. By integrating the rectifier and brake chopper, it allows for the development of much smaller and more cost-effective drives without compromising on performance or functionality.

- High-Performance Servo Drives: In robotics and CNC machining, precision and reliability are paramount. The integrated protection circuits and direct temperature sensing of the SKiiP 25AC126V1 simplify the control loop and provide the robust fault handling necessary for high-dynamic motion control.

- Industrial Pumps, Fans, and Compressors: For applications requiring continuous operation, long-term reliability is the key purchasing driver. The module's pressure contact technology ensures a lower total cost of ownership by minimizing downtime and maintenance requirements.

Key Technical Specifications

The following table outlines the critical performance parameters for the Semikron SKiiP 25AC126V1. For a complete overview, please download the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1200 V |

| Nominal DC Collector Current (IC,nom) | 25 A |

| Collector-Emitter Saturation Voltage (VCE(sat), typ. @ IC,nom) | 1.9 V |

| Topology | CIB (Converter-Inverter-Brake) |

| Integrated Features | Gate Driver, Temperature Sensor, Protection Circuits |

Engineer's Frequently Asked Questions (FAQ)

What is the primary advantage of a PIM (Power Integrated Module) with a CIB topology?

The main advantage is system simplification. By integrating the three-phase input rectifier, brake chopper, and output inverter into one module, you significantly reduce the bill of materials (BOM), shrink the required PCB area, and simplify thermal management to a single heatsink. This leads to a faster design cycle and a more compact, reliable, and cost-effective end product.

How does the integrated gate driver simplify my design?

An integrated driver saves significant engineering effort. It is already optimized for the specific IGBTs within the module, ensuring proper gate voltage levels and timing. Furthermore, the built-in protection features like over-current and under-voltage lockout (UVLO) offload these critical safety functions from your main controller, simplifying firmware and hardware design. For complex designs or questions about implementation, please contact our technical team for support.