Content last revised on January 17, 2026

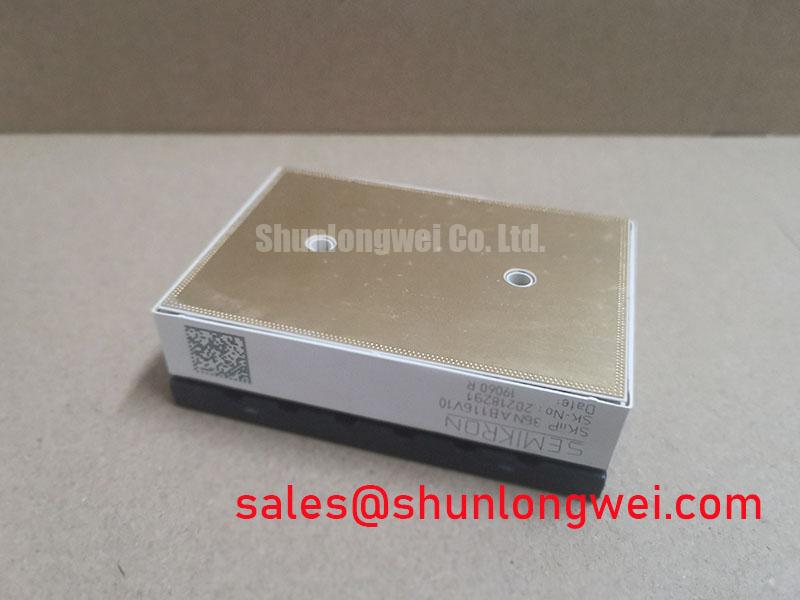

Semikron SKiiP36NAB116V10 | Fully Integrated Six-Pack IPM for High-Reliability Power Conversion

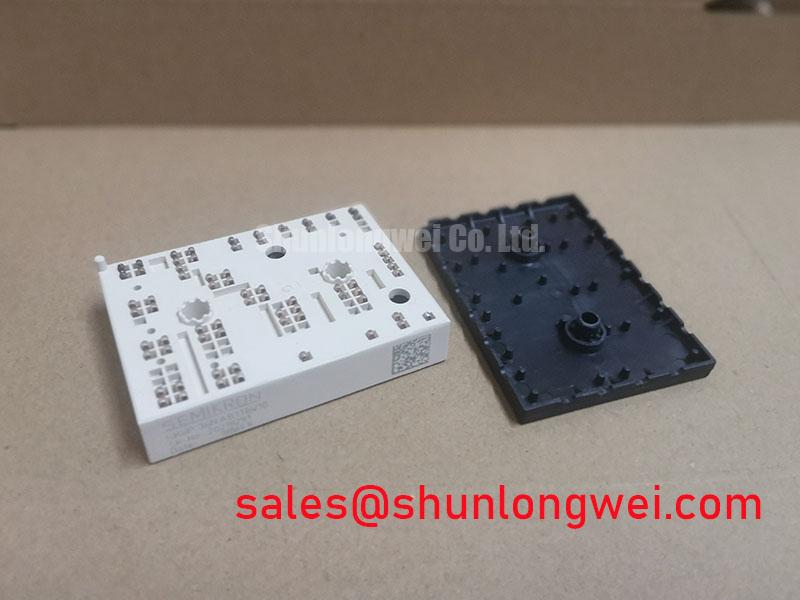

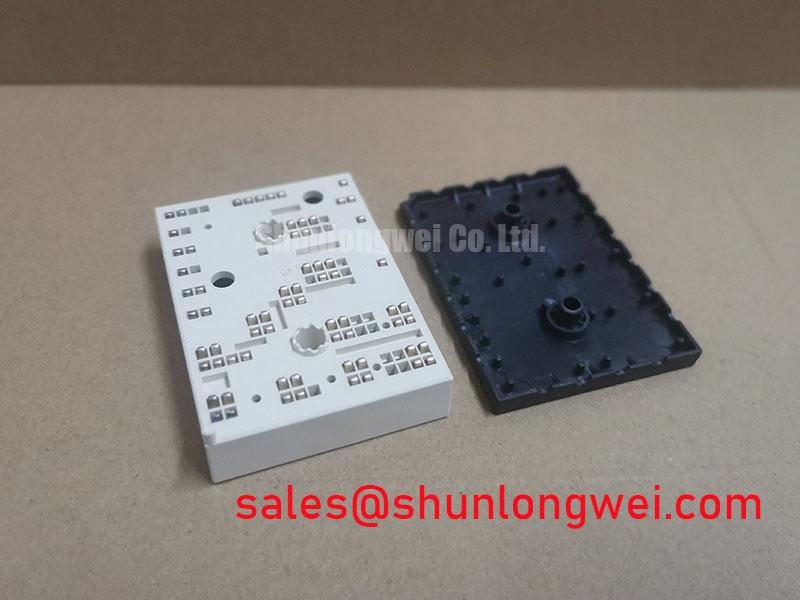

The Semikron SKiiP36NAB116V10 is an advanced Intelligent Power Module (IPM) engineered for high-performance, high-reliability power conversion systems. As a member of the renowned SKiiP family, this module integrates a complete three-phase inverter (six-pack) stage, including powerful 1200V Trench 4 IGBTs, CAL4F freewheeling diodes, and a sophisticated digital gate driver. This all-in-one solution is designed to streamline development, reduce system complexity, and maximize operational lifetime in demanding applications such as industrial motor drives, solar inverters, and uninterruptible power supplies (UPS).

- High Integration Level: Combines a six-pack IGBT configuration with an intelligent driver, current sensors, and temperature monitoring in a single, compact package.

- Solder-Free SKiiP Technology: Utilizes pressure contact and silver sintering technologies, eliminating solder joints to dramatically enhance thermal cycling and power cycling capabilities, which is a common failure point in conventional modules.

- Optimized IGBT4 Chipset: Features robust 1200V Trench 4 IGBTs and CAL4F (Controlled Axial Lifetime) diodes, delivering a superior balance of low conduction losses (VCEsat) and switching losses.

- Built-in Protection and Diagnostics: The integrated digital driver provides comprehensive protection against over-current, over-temperature, and under-voltage, while offering diagnostic feedback for enhanced system safety and reliability.

Key Parameter Overview

The technical specifications of the SKiiP36NAB116V10 are tailored for robust and efficient performance in inverter applications typically up to 75 kW. The values below represent the core electrical and thermal characteristics that empower its superior performance. For a comprehensive list of parameters, engineers can Download the Datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (V_CES) | 1200 V |

| Nominal DC Collector Current (I_Cnom) | 250 A (@ T_s = 25 °C) |

| Collector-Emitter Saturation Voltage (V_CEsat, typ.) | 1.75 V (@ I_C = 200 A, T_j = 125 °C) |

| Topology | Three-Phase Inverter (Six-Pack, B6) |

| Isolation Voltage (V_isol) | 4000 V |

| Max. Junction Temperature (T_j,max) | 175 °C |

Technical Deep Dive: The SKiiP Advantage

The superior performance of the SKiiP36NAB116V10 stems from Semikron-Danfoss's core engineering philosophies. Two key pillars are the SKiiP mounting technology and the integrated intelligence.

Solder-Free Pressure Contact System

Unlike conventional IGBT modules that rely on soldered connections, this module is built on Semikron-Danfoss's renowned SKiiP® Technology. This system uses precisely engineered pressure contacts to connect the internal substrates to the heat sink and power terminals. By eliminating solder, the module mitigates the primary cause of fatigue failure in power electronics: the mechanical stress from mismatched thermal expansion coefficients between copper and ceramic layers. This results in an exceptionally high Power Cycling Capability, extending the module's service life significantly in applications with frequent load changes.

Integrated Digital Gate Driver

The intelligent gate driver is the brain of the SKiiP36NAB116V10. It is perfectly matched to the IGBT characteristics, ensuring optimized switching performance that minimizes both losses and electromagnetic interference (EMI). This integration simplifies the complex task of robust IGBT gate drive design and provides a suite of indispensable safety features. Integrated sensors continuously monitor current and temperature, allowing the driver to react instantly to short-circuit or over-temperature events, thereby protecting the module and the entire system from catastrophic failure.

Application Scenarios & Engineering Value

The SKiiP36NAB116V10 is not just a component; it is a system-level solution that delivers tangible value across several high-power industries.

Variable Frequency Drives (VFDs)

In industrial automation, reliability is paramount. The solder-free design of the SKiiP36NAB116V10 ensures it can withstand the harsh thermal and mechanical stresses of factory environments. Its high integration level reduces the VFD's component count, simplifying assembly, shrinking the final product size, and ultimately lowering total cost of ownership. For drive systems that require scalability, a lower-power alternative like the SKiiP 35NAB126V1 offers similar technological benefits in a smaller package.

Renewable Energy Inverters

Solar and wind power generation systems are characterized by highly variable power output due to changing environmental conditions. This module is the backbone of modern wind-to-grid conversion systems. Its exceptional power cycling endurance directly translates to a longer operational lifespan and higher reliability for the central inverter, which is critical for maximizing energy harvest and ensuring a stable grid connection.

Uninterruptible Power Supplies (UPS)

For data centers, medical facilities, and other critical infrastructure, power continuity is non-negotiable. The integrated protection and diagnostic feedback of the SKiiP36NAB116V10 provide the reliability and intelligence needed for high-availability UPS systems. The module's ability to safely handle fault conditions ensures the UPS can protect its downstream load without compromising its own integrity.

FAQ (Frequently Asked Questions)

What is the primary benefit of the SKiiP pressure contact technology?

The main advantage is significantly enhanced reliability and extended service life. By eliminating solder layers, which are prone to cracking and delamination under thermal stress, the pressure contact system provides superior resilience to power and thermal cycling. This makes the module ideal for applications with fluctuating loads, such as renewable energy and industrial drives.

How does the integrated driver in the SKiiP36NAB116V10 simplify my design process?

The integrated driver eliminates the need for engineers to design, source, and validate a separate gate driver circuit. Since the driver is already optimized for the module's IGBTs, it guarantees ideal switching behavior and provides pre-validated protection features like short-circuit detection and temperature monitoring. This reduces engineering effort, accelerates time-to-market, and minimizes the risk of design errors. For more insights on this topic, explore our guide on IPM vs. Discrete IGBTs.

Is it possible to parallel SKiiP modules for higher power output?

Yes, SKiiP modules are designed to support parallel operation for scaling power. The system's architecture, including integrated current sensing and digital communication interfaces like CAN, facilitates balanced current sharing among paralleled modules. Semikron-Danfoss provides specific application notes and parallel boards to ensure proper implementation, allowing engineers to build multi-megawatt converters using these standardized power units.