Content last revised on January 31, 2026

SKiiP 35NAB126V1: Integrated Power Stage for High-Reliability Motor Drives

Introduction to a Compact, Solder-Free Power Solution

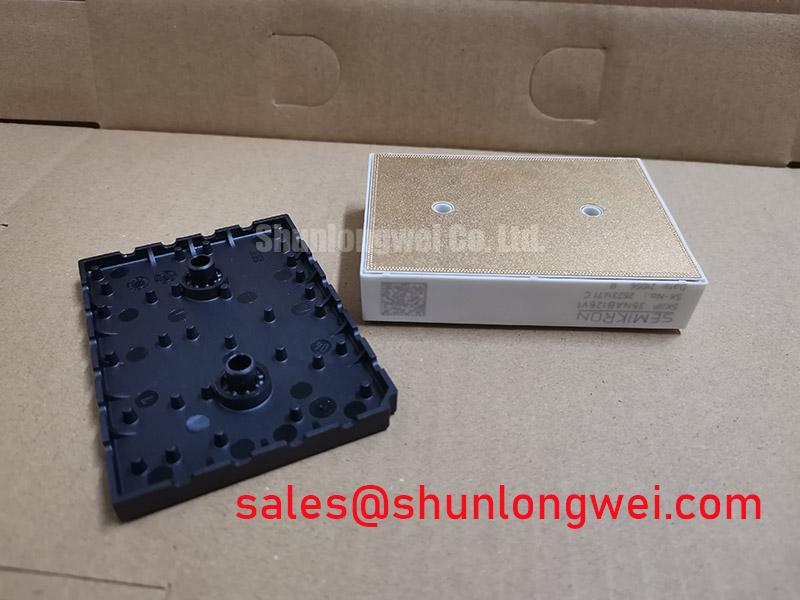

The SKiiP 35NAB126V1 is an intelligent power module (IPM) engineered for exceptional reliability and thermal efficiency in compact motor drive applications. This module integrates a three-phase rectifier, brake chopper, and a three-phase inverter into a single solder-free package, leveraging highly reliable spring contacts to eliminate a common failure point in power cycling. With core specifications of 1200V | 75A (Inverter IGBT) and Trench Field-Stop IGBT technology, it delivers superior performance. Key benefits include enhanced long-term reliability and simplified thermal management. What is the primary advantage of its spring-contact design? It eradicates solder fatigue, significantly extending operational life under harsh thermal cycling conditions. Best fit for motor drives up to 15 kW requiring a robust, all-in-one power core with predictable long-term performance.

Application Scenarios & Value

Achieving System-Level Benefits in High-Frequency Power Conversion

The SKiiP 35NAB126V1 is engineered for demanding, space-constrained applications where reliability and ease of assembly are paramount. Its primary application is in variable frequency drives (VFDs) for industrial motors, typically up to 15 kW. In this context, engineers face the challenge of managing significant thermal loads generated during high-frequency switching while ensuring a long operational lifespan. The module's integrated nature, combining the input rectifier, brake chopper, and output inverter, drastically simplifies the power stage design and assembly process. This high level of integration is crucial for developing compact VFDs. The use of Semikron's SKiiP® Technology with its spring-loaded contacts, rather than solder joints, directly addresses the critical failure mode of solder fatigue, making it exceptionally suited for applications with frequent temperature fluctuations, such as conveyor systems or robotics servo drives. For systems demanding higher power output, the related SKiiP39AC126V20 offers increased current handling capabilities within the SKiiP family.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the SKiiP 35NAB126V1 are tailored for efficiency and durability in inverter applications. The parameters below highlight the module's capacity to handle demanding electrical and thermal loads. A key parameter is the low collector-emitter saturation voltage (VCE(sat)) of 1.9V (typical at 50A). This specification is analogous to friction in a mechanical system; a lower value means less energy is wasted as heat during operation. This directly translates to higher inverter efficiency and a reduced burden on the cooling system, enabling more compact and cost-effective heatsink designs.

| Parameter | Inverter / Brake Chopper | Rectifier Diode | Conditions |

|---|---|---|---|

| Max. Collector-Emitter Voltage (VCES) | 1200 V | N/A | Tj = 25 °C |

| Nominal Collector Current (IC,nom) | 50 A | N/A | Tcase = 70 °C |

| Max. Repetitive Forward Current (IFRM) | N/A | 80 A | Tcase = 70 °C |

| Collector-Emitter Saturation Voltage (VCE(sat)) | 1.9 V (typ.) / 2.35 V (max.) | N/A | IC = 50 A, Tj = 125 °C |

| Thermal Resistance, Junction-to-Case (Rth(j-c)) | ≤ 0.55 K/W (per IGBT) | ≤ 0.8 K/W (per Diode) | |

| Technology | Trench Field-Stop IGBTs, CAL (Controlled Axial Lifetime) Freewheeling Diodes | ||

| Isolation Voltage (Visol) | 2500 V (AC, 1 min.) | ||

Download the SKiiP 35NAB126V1 datasheet for detailed specifications and performance curves.

Industry Insights & Strategic Advantage

Leveraging Solder-Free Integration for Enhanced Total Cost of Ownership

In the drive towards Industry 4.0 and increased automation, the reliability of core components like IGBT modules is a strategic imperative. The SKiiP 35NAB126V1 addresses this by replacing traditional solder connections with a pressure contact system. This design choice is a direct response to a major industry challenge: solder joint fatigue and delamination, which are leading causes of power module failure over long operational periods. By eliminating solder, the module offers a quantifiable increase in power cycling capability and operational lifetime. This translates to a lower total cost of ownership (TCO) for the end equipment, as it reduces maintenance cycles and minimizes downtime. For OEM engineers, this solder-free approach not only boosts product reliability but also simplifies the manufacturing process, as the module can be mounted quickly and reliably without the need for specialized soldering equipment. This focus on reliability and manufacturability aligns perfectly with the demands of modern industrial environments where uptime is critical.

Frequently Asked Questions (FAQ)

What is the primary benefit of the integrated three-phase rectifier in the SKiiP 35NAB126V1?

The integrated rectifier simplifies the overall system design by reducing component count, minimizing required PCB space, and streamlining the assembly process. This leads to a more compact and cost-effective power conversion stage for motor drives and other inverter systems.

How does the CAL freewheeling diode technology contribute to the module's performance?

The Controlled Axial Lifetime (CAL) diode technology provides a soft and robust reverse recovery characteristic. This "softness" is critical for reducing electromagnetic interference (EMI) and minimizing voltage overshoots during high-frequency switching, which improves the reliability of the entire system and can simplify EMC compliance efforts.

Strategic Outlook

The SKiiP 35NAB126V1 represents a strategic choice for engineers developing next-generation industrial drives and power conversion systems. Its design philosophy, centered on solder-free integration and proven Semikron Danfoss technologies, provides a clear path to enhanced system reliability and a streamlined manufacturing process. By addressing the fundamental failure mechanism of solder fatigue, this module offers a robust foundation for building equipment with a longer service life and lower field maintenance costs. Adopting this integrated power stage allows design teams to focus on higher-level system innovation, confident in the durability of the core power electronics.