Content last revised on November 7, 2025

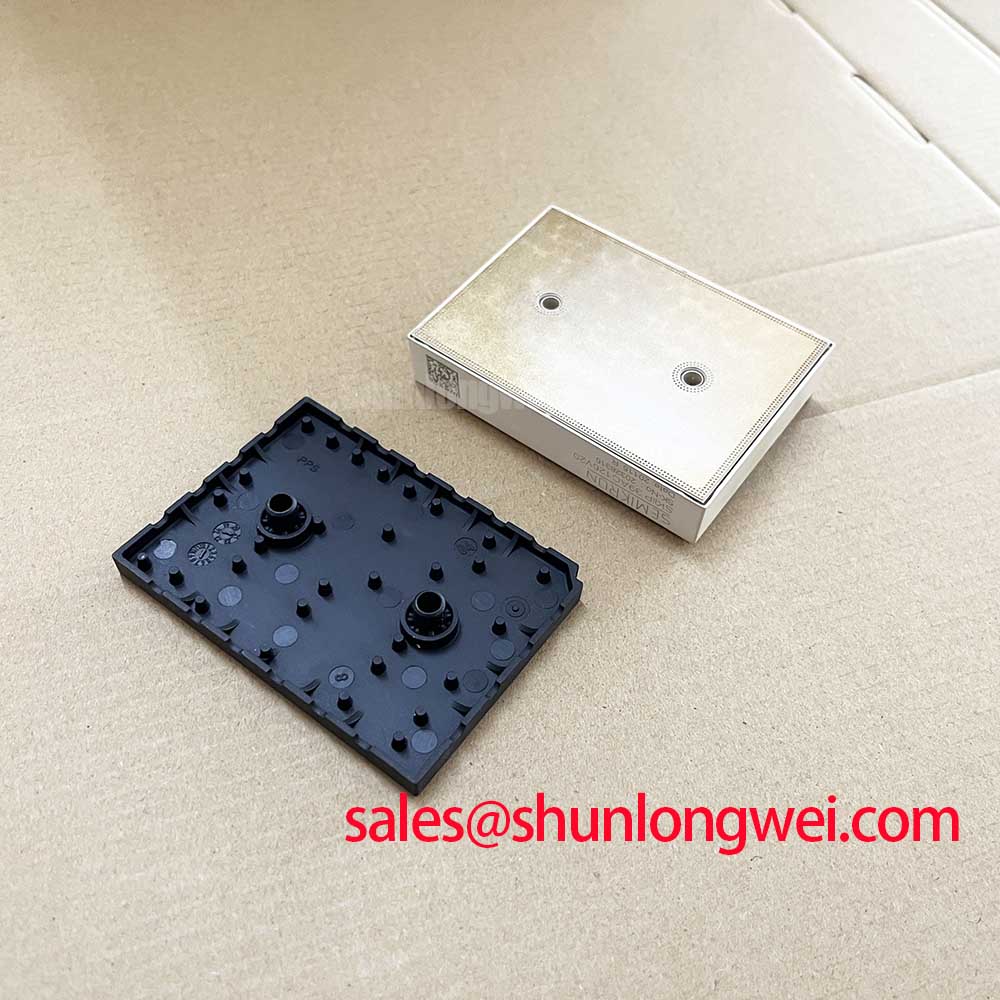

SKiiP39AC126V20: 1200V 390A Intelligent Power Module for High-Reliability Inverters

Product Overview

Defining Efficiency and Reliability in a Single Integrated Package

The SKiiP39AC126V20 is an advanced Intelligent Power Module (IPM) engineered for high-power conversion systems where thermal performance, reliability, and design simplification are paramount. It integrates a three-phase inverter bridge using 1200V Trench Field-Stop IGBTs and anti-parallel CAL diodes, managed by a sophisticated gate driver unit. With a nominal current rating of 390A and a low typical VCE(sat) of 1.9V, this module delivers robust performance with high efficiency. Key benefits include drastically simplified gate drive design and superior thermal management. This integrated approach directly addresses the engineering challenge of reducing design complexity and improving system reliability in high-power motor drives and inverters. For high-power industrial inverters up to 150 kW requiring robust thermal management and simplified assembly, the SKiiP39AC126V20 provides a streamlined, reliable solution.

Application Scenarios & Value

System-Level Benefits in Demanding Industrial Drive and Inverter Applications

The SKiiP39AC126V20 is purpose-built for high-reliability applications such as industrial motor drives, commercial air conditioning systems, and central solar inverters. A primary engineering challenge in these systems is managing transient overload conditions, such as a motor startup in a Variable Frequency Drive (VFD), which can cause significant thermal stress. The module's low thermal resistance from junction to case, Rth(j-c) per IGBT at a typical 0.14 K/W, is critical. This parameter ensures rapid and efficient heat transfer away from the semiconductor die to the heatsink. This prevents the junction temperature from exceeding its maximum rating of 175°C, thereby safeguarding the drive against thermal runaway and ensuring operational integrity and long service life. What is the benefit of its integrated gate driver? It significantly reduces design time and component count, enhancing system reliability.

This module's capabilities are well-suited for systems in the 75 kW to 150 kW power range. For applications requiring a different power level but the same integrated topology, the related SKiiP 25AC12T4V1 offers a solution for lower-power systems, while Vincotech's offerings can cater to even higher power requirements.

Key Parameter Overview

Functionally Grouped Specifications for System Design

The technical specifications of the SKiiP39AC126V20 are organized below to provide a clear overview for system-level design and evaluation. The parameters are grouped by their function within the module—Inverter Stage, Gate Driver & Protection, and Thermal/Mechanical properties—to facilitate a targeted analysis.

| Absolute Maximum Ratings (Tcase = 25°C unless otherwise specified) | |

| Parameter | Value |

| Collector-Emitter Voltage (Vces) | 1200 V |

| DC Collector Current (IC) @ Tcase = 25°C | 390 A |

| DC Collector Current (IC) @ Tcase = 70°C | 300 A |

| Pulsed Collector Current (ICpuls) | 600 A |

| Total Power Dissipation (Ptot) | 1350 W |

| Inverter IGBT / Diode Characteristics (Tj = 150°C) | |

| Collector-Emitter Saturation Voltage (VCE(sat)), typ. @ IC,nom | 1.9 V |

| Forward Voltage, Diode (VF), typ. @ IF,nom | 1.8 V |

| Turn-on Switching Energy (Eon), typ. | 45 mJ |

| Turn-off Switching Energy (Eoff), typ. | 57 mJ |

| Thermal and Mechanical Characteristics | |

| Thermal Resistance, Junction to Case (Rth(j-c)), per IGBT | 0.14 K/W (typ.) |

| Operating Junction Temperature (Tj,op) | -40 to +175 °C |

| Isolation Voltage (Visol) | 4000 V (AC, 1 min) |

Download the SKiiP39AC126V20 datasheet for detailed specifications and performance curves.

Technical Deep Dive

Analyzing the Synergy of Integrated Gate Drive and Low-Inductance Design

A deeper analysis of the SKiiP39AC126V20 reveals how its integrated design delivers more than just component reduction. The co-engineered gate driver and power stage are optimized for the dynamic characteristics of the Trench Field-Stop IGBTs. This integration is like having a perfectly tuned engine control unit (ECU) paired with a high-performance engine; it ensures optimal switching behavior, minimizing voltage overshoots and ringing, which are common challenges in discrete designs. This synergy allows designers to push closer to the specified SOA (Safe Operating Area) with confidence. Furthermore, the internal layout is designed for low stray inductance. This is critical for minimizing switching losses (Eon/Eoff) and reducing EMI, simplifying system-level compliance with standards like IEC 61800-3 for adjustable speed electrical power drive systems.

Frequently Asked Questions (FAQ)

What is the primary benefit of the SKiiP39AC126V20 being an Intelligent Power Module (IPM)?

The primary benefit is system simplification and enhanced reliability. As an IPM, it integrates the power switches (IGBTs and diodes) with a dedicated gate driver that includes protection features like Under-Voltage Lockout (UVLO) and short-circuit protection. This eliminates the complex and time-consuming task of designing, testing, and qualifying a separate gate drive circuit, reducing time-to-market and potential points of failure.

How does the typical VCE(sat) of 1.9V impact the module's performance in a variable frequency drive?

A lower Collector-Emitter Saturation Voltage (VCE(sat)) directly translates to lower conduction losses during operation (Power Loss = VCE(sat) * IC). The 1.9V typical rating at nominal current and 150°C means less energy is wasted as heat when the IGBT is on. For a VFD operating continuously, this reduction in heat generation improves overall system efficiency and reduces the demands on the cooling system, potentially allowing for a smaller, more cost-effective heatsink.

What are the key advantages of the CAL (Controlled Axial Lifetime) freewheeling diodes used in this module?

CAL diodes are engineered for soft and fast recovery characteristics. This is crucial in inverter applications where the diode must turn off quickly as the opposing IGBT turns on. A "soft" recovery minimizes voltage overshoots and oscillations, which reduces electromagnetic interference (EMI) and stress on the components. This controlled behavior contributes to higher system reliability and simplifies EMI filtering design.

For engineering teams looking to accelerate their development cycle for high-power inverters and motor drives, the SKiiP39AC126V20 offers a compelling, pre-validated power stage. To discuss how this module can be integrated into your next project, please contact our technical support team for further information and design resources.