Content last revised on November 5, 2025

Semikron SKiiP 25AC12T4V1 | Integrated CIB Power Module for High-Reliability Motor Drives

Executive Summary: A New Standard in Compact Power Integration

The Semikron SKiiP 25AC12T4V1 is not just another power module; it is a fully integrated Converter-Inverter-Brake (CIB) solution engineered for superior reliability and thermal performance in demanding industrial applications. By combining a three-phase input rectifier, a brake chopper, and a three-phase output inverter into a single, compact package, this Intelligent Power Module (IPM) drastically simplifies system design. It leverages Semikron’s pioneering SKiiP® Technology, offering a robust, solder-free power stage that sets a new benchmark for operational longevity and efficiency in low-to-medium power motor control.

- Topology: Complete CIB (Converter-Inverter-Brake) for all-in-one motor drive solutions.

- Core Technology: Features 4th generation Trench Field Stop IGBTs and CAL 4 freewheeling diodes for optimized switching performance.

- Reliability: Built on Semikron's solder-free pressure contact system, eliminating thermal paste and common solder fatigue failure modes.

- Integration: Includes an integrated gate driver with full protection (UVLO, short-circuit, over-temperature), minimizing external component count.

Technical Deep Dive: The Engineering Behind the Performance

The exceptional performance of the SKiiP 25AC12T4V1 stems from a synergy of advanced semiconductor and packaging technologies. Understanding these elements is key to appreciating its value in a power system.

First is the core chipset, which pairs 1200V Trench Field Stop IGBT 4 technology with CAL 4 (Controlled Axial Lifetime) diodes. This combination is meticulously engineered to reduce total power losses. The Trench IGBTs provide an extremely low collector-emitter saturation voltage (VCE(sat)), which directly cuts down on conduction losses during operation. Simultaneously, the soft and fast-recovery characteristics of the CAL 4 diodes minimize switching losses and electromagnetic interference (EMI), simplifying the design of filters and ensuring smoother operation, especially in systems requiring high control precision.

The second, and perhaps most defining feature, is the SKiiP® pressure contact technology. Unlike conventional modules that rely on soldered connections and thermal interface materials (TIMs), this module uses a precisely engineered pressure system. This design choice offers two profound benefits: it creates a highly reliable, low-inductance connection between the module and the heatsink, and it dramatically improves power cycling capability. By eliminating solder layers prone to cracking under thermal stress, the SKiiP 25AC12T4V1 is built for applications with frequent temperature swings, ensuring a significantly longer service life.

Optimized for Demanding Industrial Applications

The unique features of the Semikron SKiiP 25AC12T4V1 translate directly into tangible advantages across several key industrial sectors.

- Compact Variable Frequency Drives (VFDs): The CIB topology's high level of integration allows for a significant reduction in PCB footprint and assembly complexity. This enables the design of smaller, more power-dense VFDs without compromising on performance or reliability.

- High-Precision Servo Drives: For applications like robotics and CNC machining, control accuracy is paramount. The fast, clean switching of the IGBT4/CAL4 chipset, coupled with the integrated gate driver, provides the precise and rapid torque control necessary for demanding servo applications.

- Industrial Automation & Pumping Systems: In environments where system uptime is critical, the enhanced reliability of the pressure contact technology is a game-changer. It minimizes the risk of field failures due to thermal fatigue, making it an ideal choice for pumps, fans, and conveyors that operate continuously.

SKiiP 25AC12T4V1 Key Technical Specifications

The following table provides a high-level overview of the module's critical parameters. For a comprehensive analysis and design considerations, download the official SKiiP 25AC12T4V1 datasheet.

| Parameter | Value |

|---|---|

| Topology | CIB (Converter-Inverter-Brake) |

| Collector-Emitter Voltage (VCES) | 1200 V |

| Nominal Inverter DC Current (ICnom) | 25 A |

| Maximum Repetitive Inverter DC Current (ICRM) | 50 A |

| Typ. Inverter VCE(sat) (Tj=25°C) | 1.7 V |

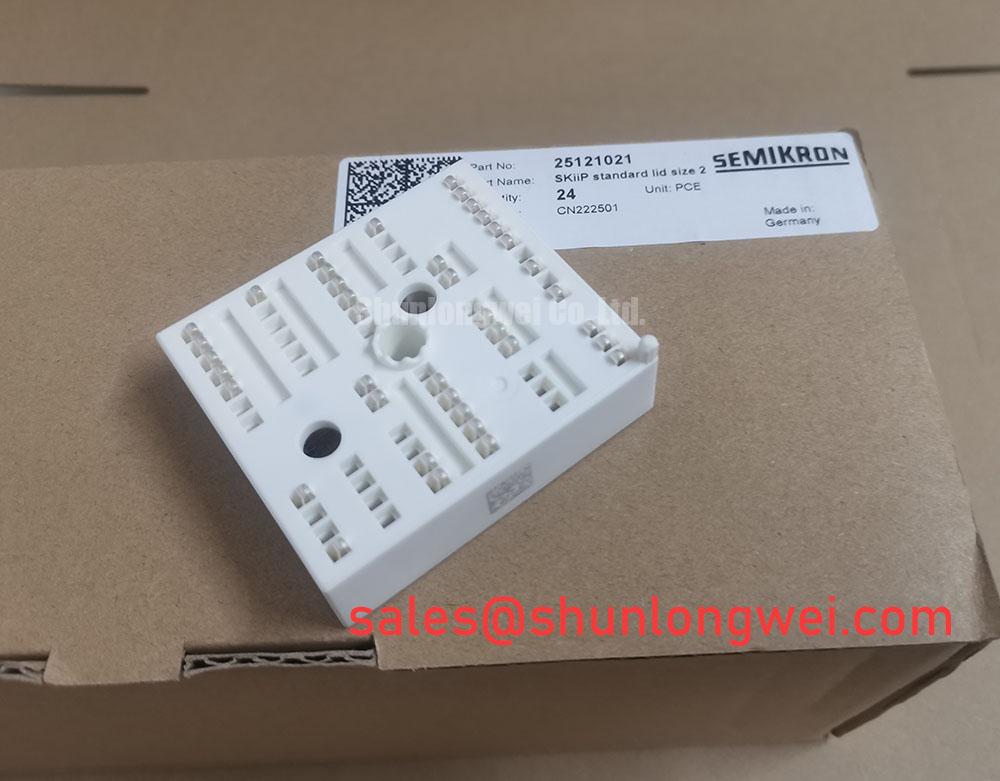

| Package | MiniSKiiP® 2 |

| Isolation Voltage (Visol) | 2500 V (AC, 1 min.) |

Frequently Asked Questions for Design Engineers

1. What is the primary benefit of the SKiiP pressure contact system over a traditional soldered module?The main advantage is superior reliability and longevity. Pressure contacts eliminate solder fatigue, which is a common failure mechanism in power modules subjected to thermal cycling. This results in a much higher power cycling capability and a longer operational life, while also simplifying assembly by removing the need for thermal paste application.

2. Is an external gate driver required for the SKiiP 25AC12T4V1?No. This is an Intelligent Power Module (IPM) that features a fully integrated, optimized gate driver. This driver includes crucial protection functions like Undervoltage Lockout (UVLO), short-circuit protection, and over-temperature feedback, which significantly simplifies the control board design and reduces development time.

For detailed application support or to discuss how the SKiiP 25AC12T4V1 can fit into your next power conversion project, please contact our technical team for expert guidance and sourcing information on our full range of IGBT modules.