Content last revised on January 26, 2026

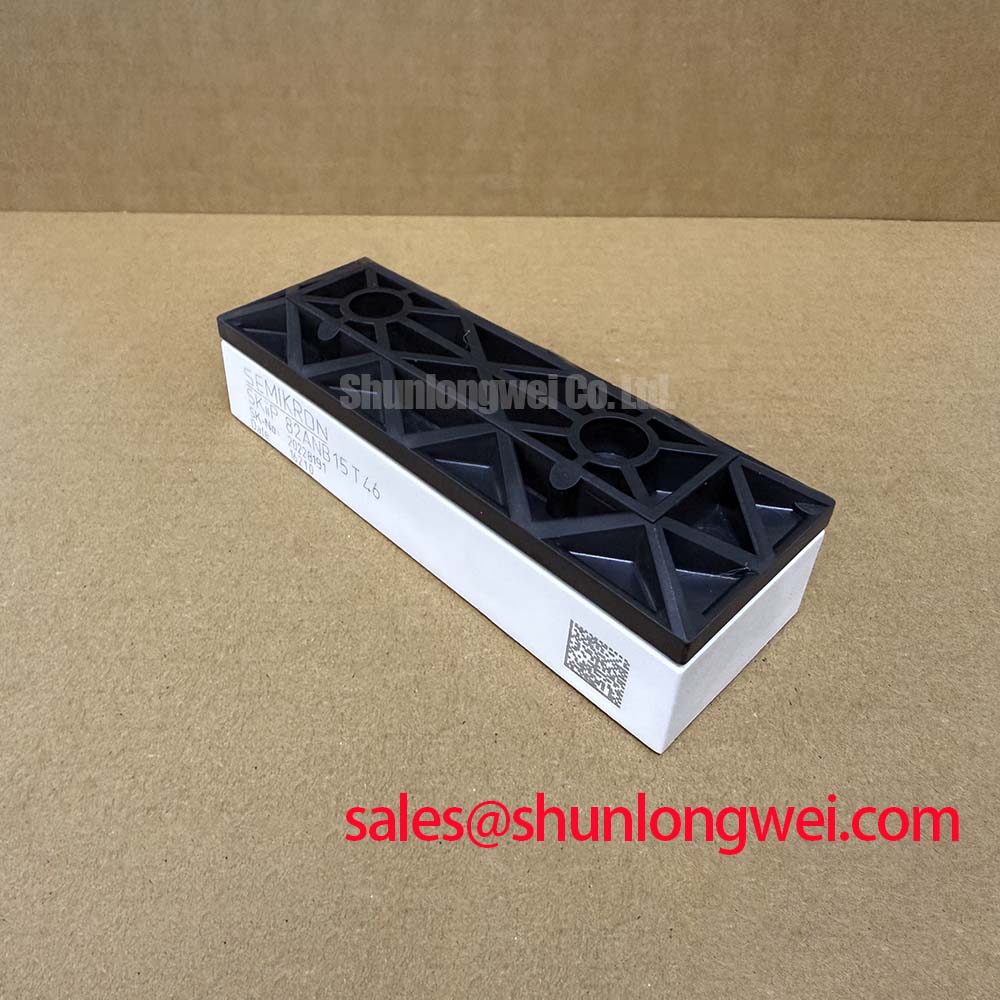

SKiiP 82ANB15T46: Integrated Power Module for High-Reliability Industrial Drives

The SKiiP 82ANB15T46 is an intelligent power module (IPM) engineered for compact and reliable power conversion systems. This module integrates a 1500V three-phase input rectifier and a 1200V IGBT braking chopper into a single, solder-free package, delivering a robust solution for demanding industrial applications. With key specifications of **1500V (Rectifier) | 100A (Rectifier @ Th=80°C) | 1200V (Chopper IGBT)**, it provides exceptional performance density. Core engineering benefits include enhanced thermal cycling capability and simplified mechanical assembly. The design directly addresses the challenge of building durable, space-efficient motor drives by combining multiple power stages and eliminating failure-prone solder joints. For industrial drive applications demanding robust performance and a compact footprint, the SKiiP 82ANB15T46 provides an optimized and reliable power core.

Application Scenarios & Value

System-Level Benefits in Motion Control and Power Conversion

The SKiiP 82ANB15T46 is engineered for applications where reliability and power density are critical design drivers. Its primary value is demonstrated in sophisticated motion control systems, such as industrial Servo Drive and Variable Frequency Drives (VFDs), which power everything from automated manufacturing lines to conveyor systems. In a high-precision CNC machine, for instance, the drive must handle rapid acceleration and deceleration cycles, which places significant thermal and mechanical stress on power components. The module's integrated nature—combining the input rectifier and a dynamic braking chopper—simplifies the power stage layout, reducing component count, minimizing potential points of failure, and shrinking the overall drive dimensions. This integration is a crucial enabler for designers aiming to meet stringent space constraints without compromising on long-term operational stability.

Furthermore, the module's 1500V rectifier stage makes it well-suited for systems connected to 575V or 690V industrial power grids, providing the necessary voltage headroom for safe and reliable operation. The integrated braking chopper efficiently dissipates regenerative energy from the motor, protecting the DC bus from overvoltage conditions and ensuring controlled deceleration. For applications requiring a complete inverter stage in addition to the front-end rectifier and chopper, the related SKiiP 35NAB126V1 integrates a full three-phase inverter, offering a more comprehensive single-module solution.

Key Parameter Overview

Functional Specifications for System Integration

The technical specifications of the SKiiP 82ANB15T46 are structured to provide a clear path for system integration. The parameters are grouped by their core function within the module: the three-phase input rectifier and the IGBT braking chopper. This functional grouping allows engineers to quickly assess the module's suitability for their specific power conversion topology.

| Parameter | Conditions | Value |

|---|---|---|

| Input Rectifier Stage (Three-Phase Bridge) | ||

| Repetitive Peak Reverse Voltage (VRRM) | - | 1500 V |

| DC Forward Current (ID) | Theatsink = 80°C | 100 A |

| Forward Voltage (VF) | IF = 75 A, Tj = 125°C | typ. 1.15 V |

| IGBT Braking Chopper | ||

| Collector-Emitter Voltage (VCES) | - | 1200 V |

| Continuous Collector Current (IC) | Theatsink = 80°C | 40 A |

| Collector-Emitter Saturation Voltage (VCE(sat)) | IC = 50 A, Tj = 125°C | typ. 3.1 V |

| Chopper Freewheeling Diode (CAL Technology) | ||

| Repetitive Peak Reverse Voltage (VRRM) | - | 1200 V |

| Continuous Forward Current (IF) | Theatsink = 80°C | 26 A |

| Module General & Thermal Characteristics | ||

| Isolation Voltage (Visol) | AC, 1 minute | 2500 V |

| Operating Junction Temperature (Tj) | - | -40 to +150 °C |

Download the SKIIP 82ANB15T46 datasheet for detailed specifications and performance curves.

Technical Deep Dive

The Engineering behind Solder-Free Pressure Contact Technology

A defining feature of the SKiiP 82ANB15T46 is its reliance on pressure contact technology, a core element of the SKiiP® Technology platform. Unlike conventional power modules that use soldered connections between the DCB (Direct Copper Bonded) substrate and the baseplate, this design eliminates solder layers entirely. Instead, it uses a precisely engineered spring system to apply consistent pressure, ensuring a reliable electrical and thermal connection. What is the primary benefit of its pressure-contact design? Enhanced long-term reliability by eliminating solder fatigue.

This approach directly counters a common failure mechanism in high-power modules: solder fatigue. During operation, frequent temperature swings (power cycles) cause different materials in the module to expand and contract at different rates. Over thousands of cycles, this mismatch in thermal expansion coefficients creates stress in the solder layers, leading to micro-cracks that degrade thermal performance and eventually cause catastrophic failure. By removing the solder, the pressure contact system creates a more resilient interface that can withstand a significantly higher number of power cycles. This is analogous to using a bolted mechanical joint instead of a welded one in a structure subjected to constant vibration; the bolted joint is designed to accommodate movement and maintain integrity, whereas a rigid weld is more prone to fatigue cracking over time. This inherent robustness makes the module an excellent choice for applications with frequent start/stop cycles or highly variable loads, such as servo drives and solar inverters.

Frequently Asked Questions (FAQ)

How does the integrated topology of the SKiiP 82ANB15T46 benefit the design of a Variable Frequency Drive (VFD)?

By combining a three-phase rectifier and an IGBT braking chopper into one component, the SKiiP 82ANB15T46 significantly reduces the complexity and physical size of the power stage in a VFD. This leads to a smaller PCB footprint, simplified assembly, reduced bus bar connections, and lower stray inductance. The result is a more compact, cost-effective, and reliable VFD design with an accelerated time-to-market.

What is the significance of the 1500V rating on the input rectifier bridge?

The 1500V rating for the rectifier diodes provides a substantial safety margin for operation on industrial three-phase AC lines, particularly 575V and 690V nominal systems. After rectification, the peak DC bus voltage can be significantly higher than the AC line-to-line RMS voltage. This high VRRM ensures the rectifier diodes can safely block these peak reverse voltages, even with voltage spikes and transients present on the grid, enhancing the overall robustness of the power conversion equipment.