Content last revised on February 1, 2026

SKiiP 37NAB12T4V1: 1200V 300A Six-Pack IGBT Intelligent Power Module

Introduction: Engineering Reliability into High-Performance Motor Drives

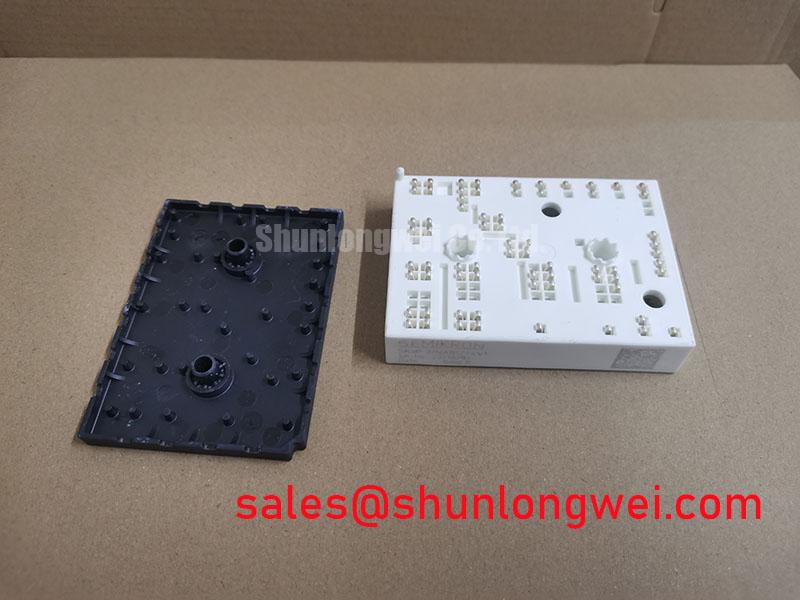

The SKiiP 37NAB12T4V1 is an intelligent power module (IPM) that delivers robust performance through superior thermal management and integrated system protection. With its core specifications of 1200V | 300A (Nominal) | Rth(j-c) 0.09 K/W, this module provides two key engineering benefits: exceptional operational lifetime and simplified system design. By integrating the gate driver and protection circuits, it directly addresses the challenge of reducing design complexity while enhancing the reliability of the power stage. For mid-power industrial drives up to 150 kW requiring simplified assembly and maximum operational lifetime, the SKiiP 37NAB12T4V1 is the definitive choice.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the SKiiP 37NAB12T4V1 are tailored for efficiency and durability in demanding power conversion systems. The module's low thermal resistance is a critical factor, enabling more effective heat dissipation and allowing for higher power density or the use of more compact cooling systems. This is analogous to a high-performance engine's cooling system; the more efficiently heat is removed, the harder and more reliably the engine can run. The following table highlights the key performance metrics based on the official datasheet.

| Parameter | Value | Conditions |

| Collector-Emitter Voltage (V_CES) | 1200 V | T_j = 25 °C |

| Nominal DC Collector Current (I_Cnom) | 300 A | T_case = 25 °C |

| Peak Repetitive Collector Current (I_CRM) | 600 A | T_case = 25 °C, t_p = 1 ms |

| Collector-Emitter Saturation Voltage (V_CEsat) | 1.75 V (typ.) | I_C = 300 A, V_GE = 15 V, T_j = 25 °C |

| Diode Forward Voltage (V_F) | 1.6 V (typ.) | I_F = 300 A, V_GE = 0 V, T_j = 25 °C |

| Thermal Resistance, Junction-to-Case (R_th(j-c)) | 0.09 K/W | Per IGBT |

| Short Circuit Withstand Time (t_sc) | 10 µs | V_CC ≤ 800 V, V_GE ≤ 15 V, T_j = 125 °C |

| Max. Junction Temperature (T_j,max) | 150 °C | - |

Download the SKiiP 37NAB12T4V1 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Industrial Motion Control

The SKiiP 37NAB12T4V1 is engineered for high-reliability applications where uptime and performance are critical. Its primary use case is in industrial Variable Frequency Drives (VFDs) and Servo Drives, which control the speed and torque of AC motors in machinery such as conveyors, pumps, fans, and robotics.

Consider the engineering challenge of a VFD in a logistics sorting center, where conveyor belts constantly start, stop, and change speed. These dynamic loads create significant thermal stress on power electronics. The SKiiP 37NAB12T4V1's solder-free pressure contact technology directly mitigates this challenge by eliminating solder fatigue, a common failure point in conventional modules. This results in superior power cycling capability, translating to a longer operational lifespan and reduced maintenance costs for the end system. The integrated driver, with its robust overcurrent and over-temperature protection, further simplifies the design and ensures safe operation under fault conditions. For systems with slightly different power requirements, the related Skiip38NAB12T4V1 offers an alternative power rating within the same technology family.

Frequently Asked Questions (FAQ)

What is the primary benefit of the SKiiP pressure-contact technology used in the SKiiP 37NAB12T4V1?

The key advantage is significantly enhanced long-term reliability. By eliminating soldered connections between the DBC substrate and the baseplate, the module is immune to solder fatigue failure caused by thermal cycling. This leads to a much higher power cycling lifetime compared to traditional soldered modules, making it ideal for applications with frequent load changes like motor drives and servo applications.

How does the integrated gate driver in this Intelligent Power Module (IPM) simplify system design?

The integrated driver board includes optimized gate drive circuitry, protection features like Undervoltage Lockout (UVLO), short-circuit protection, and over-temperature feedback. This integration saves significant engineering time and resources, as designers do not need to develop, test, and qualify a separate gate driver circuit. It also reduces component count, simplifies the PCB layout, and minimizes parasitic inductance for cleaner switching performance.

How does the module's 0.09 K/W thermal resistance impact heatsink selection?

A lower thermal resistance value indicates more efficient heat transfer from the semiconductor junction to the case. The excellent Rth(j-c) of 0.09 K/W means that for a given power loss, the junction temperature will be lower. This gives engineers two options: they can either operate the module at higher power outputs while staying within thermal limits, or they can select a smaller, more cost-effective heatsink for the same power level, thereby improving the overall system's power density and cost structure. A comprehensive guide to mastering IGBT thermal management can provide further context.

Technical Deep Dive

A Closer Look at Solder-Free Design for Long-Term Reliability

At the core of the SKiiP 37NAB12T4V1's durability is the Semikron SKiiP® Technology, which employs a pressure contact system for all electrical and thermal interfaces. In a conventional power module, the different layers are soldered together. Because materials like copper and ceramic expand and contract at different rates with temperature changes, these solder layers are put under immense mechanical stress, eventually leading to cracks and module failure.

The pressure contact system works like a high-quality, pre-loaded spring assembly. It maintains a consistent, high-pressure connection across the operating temperature range, completely avoiding the use of fatigue-prone solder. This is mechanically analogous to using bolted busbars instead of soldered wires for a high-vibration connection; the bolted joint offers superior mechanical stability and long-term integrity. For power electronics, this translates directly to a system that can withstand more frequent and wider temperature swings, a critical requirement for modern, energy-efficient drives that operate under variable load conditions.

Strategic Design Considerations

Integrating the SKiiP 37NAB12T4V1 into a power system is a strategic decision that prioritizes total cost of ownership over initial component price. The module's all-in-one design, combining the power stage with an intelligent driver, accelerates the development cycle and reduces assembly complexity. This approach allows engineering teams to focus on higher-level system optimization, such as implementing advanced motor control algorithms or improving user interface design, rather than on the intricacies of gate drive and protection circuits. The proven reliability of the solder-free platform reduces field failures and warranty costs, strengthening the business case for high-performance industrial equipment where operational continuity is paramount.