Content last revised on January 20, 2026

SKiiP603GB172CT IGBT: Reliable 1700V Power Conversion

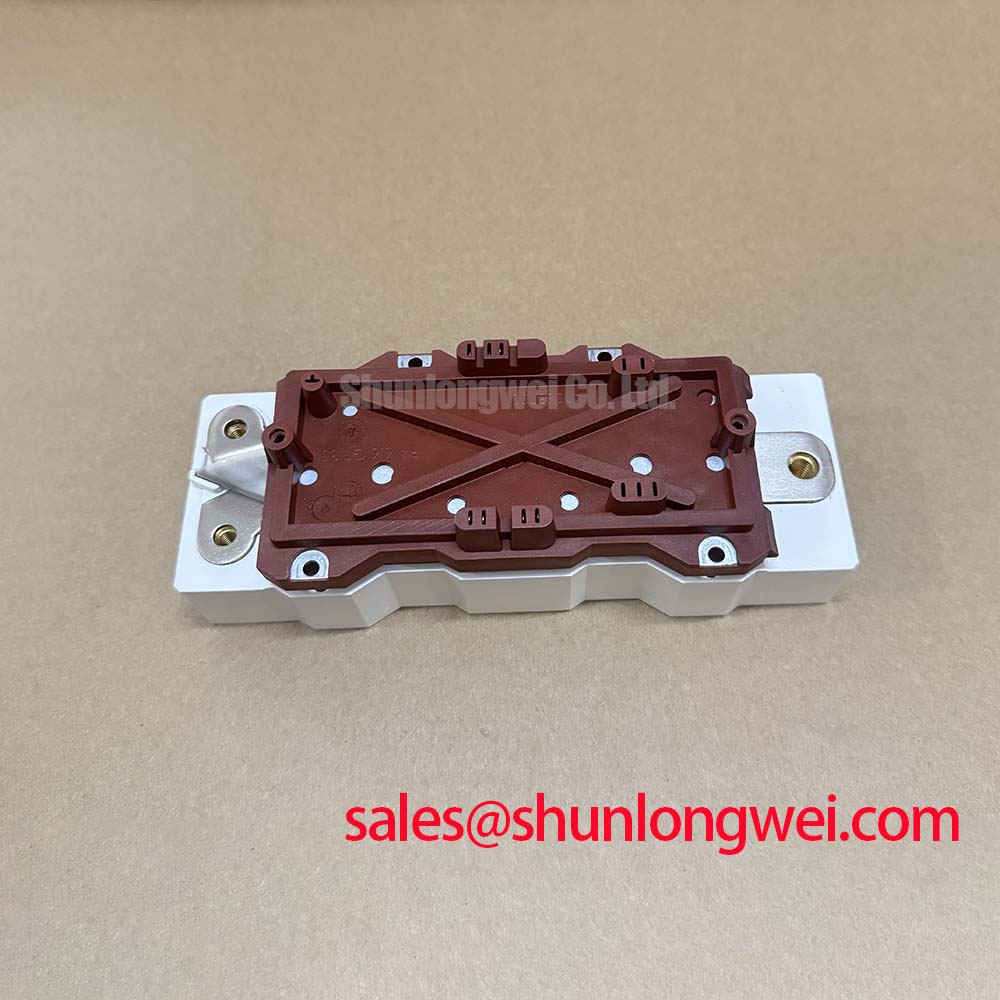

Engineered for exceptional operational lifetime, the Semikron SKiiP603GB172CT is an intelligent power module that leverages solder-free pressure contact technology to mitigate common failure modes in high-power systems. It combines robust electrical characteristics with superior thermal management, providing a durable foundation for demanding power conversion applications. The module's design directly addresses the engineering challenge of long-term reliability by eliminating solder fatigue, ensuring consistent performance throughout its service life.

Applications Forged in Extreme Temperatures

The robust thermal design of the SKiiP603GB172CT makes it an exemplary component for systems where thermal cycling and high ambient temperatures are standard operating conditions. Its architecture is particularly advantageous in applications where maintenance is difficult or costly, and long-term reliability is a primary design criterion. What defines the SKiiP603GB123CT's reliability? Its solder-free pressure contact system, which prevents common fatigue-related failures. For multi-megawatt wind converters where maintenance is costly, the SKiiP603GB172CT's low thermal resistance offers a quantifiable advantage in system longevity.

- Renewable Energy Systems: Ideal for the main inverter stage in multi-megawatt wind turbines and large-scale solar power plants, where uptime and resilience to environmental stress are critical.

- Industrial Motor Drives: Powers high-torque AC motor drives in heavy machinery, such as mining conveyors, pumps, and manufacturing automation, ensuring continuous operation under heavy loads.

- Traction and Transportation: Suitable for auxiliary power converters and main propulsion in railway systems and heavy-duty electric vehicles, offering dependable performance despite mechanical vibrations and thermal shocks.

Meeting the Demands of Modern Power Grids and Drives

As industrial and renewable energy sectors push for higher efficiency and greater power density, the demand for power modules with superior thermal performance and proven longevity intensifies. The SKiiP603GB123CT directly addresses this trend. Its 1700V rating provides the necessary safety margin for 690V AC grid-tied applications, while its internal construction is optimized to handle the repetitive thermal stress inherent in these systems. This focus on durability helps system designers reduce the total cost of ownership by minimizing downtime and extending maintenance intervals, a key strategic advantage in today's competitive landscape.

Field-Validated Reliability in Demanding Environments

The underlying Semikron SKiiP® Technology has a long track record of successful deployment in some of the world's most challenging power conversion environments. This module's pressure contact design is a core element of that success. Unlike soldered connections that can degrade and fail over time due to thermal expansion and contraction, the pressure contact system maintains a consistent, high-integrity connection. This is analogous to a vehicle's suspension system, which flexes to absorb road imperfections, whereas a rigid, welded joint would be prone to cracking under constant stress. This inherent mechanical resilience translates directly to a longer and more predictable operational life for the end system.

Inside the SKiiP 603 GB 172 CT: A Focus on Thermal Integrity

A granular analysis of the SKiiP603GB172CT reveals a design philosophy centered on heat management and long-term stability. The module integrates six IGBTs and six freewheeling diodes in a three-phase bridge configuration. The key to its performance lies in how these silicon components are integrated into the overall package. The elimination of base plate solder and the use of a direct pressure contact system create an exceptionally efficient thermal pathway from the semiconductor junction to the heatsink. This design significantly lowers the thermal resistance, a critical factor in managing heat dissipation. Furthermore, the integrated NTC temperature sensor provides a direct, real-time measurement of the module's thermal state, enabling precise and responsive over-temperature protection mechanisms within the gate driver and control system.

Datasheet at a Glance: Critical Specifications for SKiiP603GB172CT

The following parameters are essential for system design and evaluation. For complete details, please refer to the official datasheet.

| Parameter | Value |

|---|---|

| Absolute Maximum Ratings (per switch) | |

| Collector-Emitter Voltage (VCES) | 1700 V |

| Continuous DC Collector Current (IC) | ICnom = 600 A / IC @ Ts=25°C = 850 A |

| Gate-Emitter Voltage (VGES) | ±20 V |

| Short Circuit Withstand Time (tsc) | 10 µs |

| Thermal and Mechanical Characteristics | |

| Thermal Resistance, Junction to Heatsink (Rth(j-s)) | 0.045 K/W (IGBT) |

| Operating Junction Temperature (Tj op) | -40 to +150 °C |

| Isolation Voltage (Visol) | 4000 V (AC, 1 min.) |

Engineering Trade-offs: A Data-Centric Perspective

When evaluating power modules, engineers must balance multiple performance vectors. The SKiiP603GB172CT is clearly optimized for applications where long-term thermal cycling capability and mechanical robustness are paramount. Its design provides a distinct advantage over modules that rely on traditional soldering for all internal connections. While other modules may offer slightly lower switching losses at very high frequencies, the SKiiP603GB172CT excels in moderate-frequency, high-power applications where reliability over a 15-20 year design life is the primary concern. For systems that need to scale to higher currents while maintaining the 1700V rating and reliability features, the SKiiP1803GB172-3DFW may be considered as part of the same technology family.

Empowering Your Design with Reliable Power

The technical data presented provides a foundation for integrating the SKiiP603GB123CT into your power conversion system. By leveraging its inherent reliability and superior thermal characteristics, engineering teams can design more compact, efficient, and durable products. For detailed application notes, gate driver compatibility, and thermal modeling support, we encourage you to consult the manufacturer's official documentation. Should you require further information to finalize your design evaluation, please feel free to contact us with your specific technical inquiries.