Wind Turbine Converters: How IGBTs Tame Unstable Wind for Grid Integration

The global push for renewable energy has placed wind power at the forefront of our transition to a sustainable future. However, harnessing the wind is not as simple as putting up a turbine and connecting it to the grid. The very nature of wind—its variability and intermittency—poses a significant challenge to the stability of our electrical grid, which demands a constant, predictable supply of power at a precise frequency. This is where power electronics, and specifically the Insulated-Gate Bipolar Transistor (IGBT), play a pivotal role. The converter system within a wind turbine, powered by IGBT modules, is the unsung hero that tames volatile wind energy, converting it into high-quality, grid-compliant electricity.

For engineers and system designers, understanding the function of these components isn’t just academic; it’s critical for developing efficient, reliable, and cost-effective wind energy systems. This article delves into the heart of the wind turbine converter, exploring how IGBTs function to bridge the gap between unpredictable wind and the stable power grid.

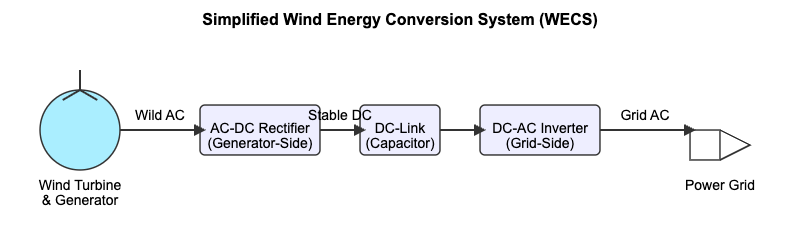

The Anatomy of a Wind Energy Conversion System (WECS)

To appreciate the role of the IGBT, we must first understand its place within the larger Wind Energy Conversion System (WECS). A modern, utility-scale wind turbine is far more than just blades and a tower. Its core purpose is to convert kinetic energy from the wind into electrical energy that is perfectly synchronized with the grid.

The process begins with the turbine blades capturing wind, which turns a rotor connected to a generator (often through a gearbox). This generator produces “wild AC” – alternating current that fluctuates in voltage and frequency as the wind speed changes. This raw power is unusable by the grid. It must be conditioned by a full-power converter system.

This converter system typically consists of two main stages connected by a DC-link capacitor:

- Generator-Side Converter (AC-DC Rectifier): This stage takes the variable AC output from the generator and converts it into a stable Direct Current (DC). By controlling this rectification process, engineers can manage the generator’s torque and speed, enabling Maximum Power Point Tracking (MPPT). MPPT ensures the turbine operates at its peak aerodynamic efficiency across a wide range of wind speeds.

- Grid-Side Converter (DC-AC Inverter): This stage takes the stable DC voltage from the DC-link and synthesizes a clean, stable AC waveform. This output must precisely match the grid’s voltage (e.g., 690V), frequency (50 or 60 Hz), and phase. This is the critical grid integration step, and it’s where the performance of the IGBT is most crucial.

The IGBT module is the fundamental building block for both the generator-side and grid-side converters. Its ability to switch high currents at high voltages with remarkable speed and efficiency makes the entire conversion process possible.

The Heart of the Converter: Why IGBTs are the Unsung Heroes

An IGBT is a power semiconductor that combines the simple gate-drive characteristics of a MOSFET with the high-current and low-saturation-voltage capability of a bipolar transistor. In a wind converter, it acts as an extremely fast and robust electronic switch.

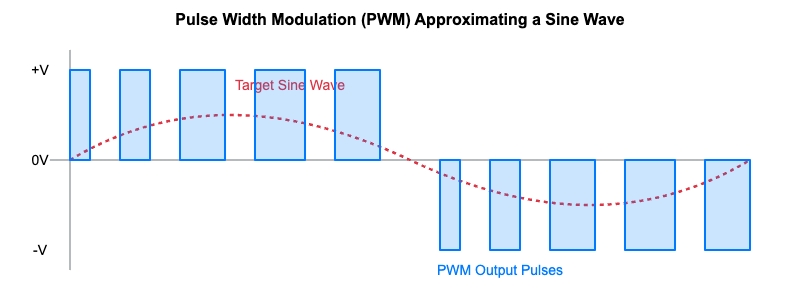

The magic happens through a technique called Pulse Width Modulation (PWM). The grid-side converter’s control system rapidly turns the IGBTs on and off thousands of times per second. By precisely varying the duration (the “width”) of the “on” pulses, the inverter can construct a high-frequency square wave that, when filtered, closely approximates a perfect sine wave at the desired grid frequency. The quality of this synthesized AC power, measured by its Total Harmonic Distortion (THD), is directly related to the performance of the IGBTs and the sophistication of the PWM algorithm.

For megawatt-scale wind applications, several IGBT characteristics are non-negotiable:

- High Voltage & Current Ratings: Wind turbines operate at high power levels, requiring IGBTs that can handle DC-link voltages of 1100-1500V and continuous currents of hundreds or even thousands of amperes.

- Low Power Losses: Efficiency is paramount. Power lost as heat in the converter is power that isn’t sold to the grid. Key parameters include low collector-emitter saturation voltage (Vce(sat)), which dictates conduction losses, and low switching energy (Eon/Eoff), which determines switching losses. Minimizing these losses is a core goal in IGBT power loss calculation.

- Robustness and Reliability: Wind turbines are often located in harsh, remote environments with wide temperature fluctuations. IGBT modules must be built to withstand these conditions, offering high short-circuit withstand times and excellent power cycling capability to handle the constant variations in wind power.

- Fast Switching Speed: Higher PWM frequencies lead to lower THD and smaller, less expensive filtering components. However, this must be balanced against increased switching losses. Modern IGBTs, like those found in our extensive IGBT module catalog, are optimized for this balance.

Key Converter Topologies for Wind Applications: A Comparative Look

As wind turbines have grown in power, converter topologies have evolved to improve efficiency and power quality. While simple 2-level inverters are sufficient for smaller systems, large-scale wind applications predominantly use multilevel inverter topologies.

The most widely adopted of these is the 3-Level Neutral-Point Clamped (NPC) inverter. Unlike a 2-level inverter that switches between the positive and negative DC rails, a Neutral Point Clamped inverter introduces a third, middle voltage level (the neutral point). This approach offers significant advantages for high-voltage applications.

Here’s a comparison between the two:

| Parameter | 2-Level Inverter | 3-Level NPC Inverter |

|---|---|---|

| Output Voltage Steps | 2 Levels (+Vdc/2, -Vdc/2) | 3 Levels (+Vdc/2, 0, -Vdc/2) |

| Voltage Stress on IGBTs | Full DC-link voltage (Vdc) | Half DC-link voltage (Vdc/2) |

| Output Power Quality (THD) | Higher; requires large output filters | Lower; waveform is closer to sinusoidal, requiring smaller filters |

| Switching Losses | Higher, due to switching the full DC voltage | Lower, as each device switches only half the voltage |

| Complexity & Component Count | Simpler, fewer components per phase | More complex, requires more IGBTs and clamping diodes per phase |

| Ideal Application | Lower voltage, lower power systems | Medium-to-high voltage, high power systems (e.g., >1 MW wind turbines) |

The reduced voltage stress on the switches in an IGBT multilevel inverter is a game-changer. It allows for the use of lower-voltage-rated IGBTs, which typically have better performance characteristics (lower Vce(sat) and faster switching). This leads to higher overall system efficiency and superior power quality, making the 3-Level NPC topology the industry standard for modern wind converters.

Selecting the Right IGBT Module for Your Wind Converter Design: An Engineer’s Checklist

Choosing the correct IGBT module is one of the most critical design decisions. A mistake here can lead to inefficiency, thermal issues, or premature failure. Here is a practical checklist for engineers:

- Verify Voltage and Current Ratings: The module’s blocking voltage (Vces) must exceed the maximum DC-link voltage with a sufficient safety margin (typically 40-50%). The continuous current rating must handle the nominal power, while its peak current capability must accommodate transient overloads during grid faults or wind gusts.

- Analyze Thermal Performance: The module’s thermal resistance from junction to case (Rth(j-c)) is critical. A lower value means heat can be extracted more efficiently. The choice of baseplate material (e.g., copper for standard performance, AlSiC for superior thermal cycling) and substrate technology (e.g., DCB, AMB) directly impacts reliability and lifetime.

- Evaluate the Package and Topology: Standard high-power packages, such as those offered by major manufacturers like Infineon or Mitsubishi, are designed for low stray inductance and easy paralleling. For NPC topologies, integrated modules that contain multiple IGBTs and diodes in the correct configuration can simplify assembly and improve performance.

- Prioritize Reliability and Lifetime Data: Wind power is a long-term investment. Look for modules with extensive reliability data, particularly power cycling curves. This data helps predict the module’s lifetime under the specific thermal stresses of a wind power profile. Reputable suppliers like SLW-ELE.COM provide access to components with proven track records in demanding applications.

- Consider the Freewheeling Diode (FWD): The diode integrated into the IGBT module is just as important as the IGBT itself. It must have soft and fast recovery characteristics (low Qrr and trr) to minimize turn-on losses in the opposing IGBT.

The Future: Trends Shaping IGBTs in Wind Power

The technology for IGBTs in wind power is continuously advancing, driven by the demand for larger turbines and lower levelized cost of energy (LCOE).

- Higher Power Density: Manufacturers are packing more power into smaller, more efficient packages. This reduces the overall size and cost of the converter system.

- Hybrid and Full SiC Modules: While silicon IGBTs remain dominant, Silicon Carbide (SiC) is making inroads. Hybrid modules combining Si IGBTs with SiC freewheeling diodes are already common, offering lower switching losses. Full SiC modules promise even higher efficiency and operating temperatures, though at a higher cost.

- Enhanced Reliability Features: New module designs incorporate advanced bonding and sintering technologies to improve thermal performance and dramatically increase power cycling lifetime. Integrated temperature and current sensors are also becoming more common, enabling real-time condition monitoring and predictive maintenance.

Conclusion: The Indispensable Role of IGBTs in a Green Energy Future

The smooth integration of volatile wind energy into our stable power grids is a modern engineering marvel, and the IGBT module is at its very core. By functioning as highly efficient, controllable switches within sophisticated converter topologies, IGBTs perform the essential task of transforming chaotic “wild AC” into clean, grid-compliant power. Their performance directly dictates the efficiency, reliability, and economic viability of wind power projects.

As turbine technology scales to 15 MW and beyond, the demands on these power electronic components will only intensify. For engineers and procurement managers, a deep understanding of IGBT characteristics, converter topologies, and selection criteria is essential. Partnering with a knowledgeable supplier who can provide reliable, high-performance IGBT modules is the first step toward building the robust renewable energy systems of tomorrow.