“2021 is known as the first year of composite robots, which means that the industry recognizes composite robots as an important trend in future technological development. As with human legs, hands, and eyes, composite robots can meet the increasingly subdivided production needs of industrial application scenarios. Some Chinese industrial media estimates that by 2025, the sales of local composite robots are expected to exceed 12,000 units.

“

2021 is known as the first year of composite robots, which means that the industry recognizes composite robots as an important trend in future technological development. As with human legs, hands, and eyes, composite robots can meet the increasingly subdivided production needs of industrial application scenarios. Some Chinese industrial media estimates that by 2025, the sales of local composite robots are expected to exceed 12,000 units.

As early as February 2020, Mobile Industrial Robots (hereinafter referred to as: MiR), the leader in the global mobile robot market, and Universal Robots (hereinafter referred to as UR) joined hands to invest 36 million US dollars to jointly establish a collaborative robot in Denmark Center, and join forces to develop the composite robot market.

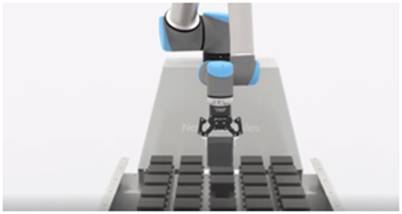

MiR’s autonomous mobile robot (Autonomous Mobile Robot C AMR) can be combined with UR’s collaborative robot arm and related fixtures to form a composite mobile collaborative robot. The composite robot has both the ability of autonomous navigation of the AMR driving chassis, as well as the precise grasping, identification, loading and unloading functions of the collaborative robot arm, and can undertake various automation tasks in industrial manufacturing scenarios to meet flexible needs.

Flexible and safe superimposed fine movements, compound robots have significant advantages

The advantage of MiR AMR is its flexibility and safety. On the one hand, dual laser scanners and a number of safety function configurations can ensure the stable operation of the robot in a human-machine mixed-flow operating environment, including area shielding, safety limit speed, safety protection parking, system emergency parking, etc., which can fully avoid collision accidents. On the other hand, AMR’s autonomous navigation technology means that it can be deployed quickly without changing any physical environment. MiR AMR is easy to use, and ordinary employees can learn to operate it after a short period of training.

The AMR with a collaborative robotic arm has been fully expanded. Taking the UR robotic arm as an example, it can complete delicate work including packaging and palletizing, quality inspection, pick and place, welding, assembly and even quality inspection. These expanded functions are suitable for fast-moving consumer goods, warehousing and logistics, industrial manufacturing, 3C precision production and other fields.

Precise scanning, quality inspection sample picking automation

Taking the fast-moving goods industry as an example, in the face of a wide variety of products and shorter production cycles, manufacturing needs to meet the multi-level requirements of shorter market delivery times, more punctuality and greater price pressure.workshop as any manufacturing enterprise

Its efficiency management directly affects the completion of various indicators of product “quality, cost, delivery time”. The MiR AMR equipped with the UR robot arm can shoulder the autonomous movement of the production line, realize the automatic selection and transportation of quality inspection samples from the production line to the quality inspection laboratory and storage area, simplify the related work process, and help the production line improve efficiency. .

Precise grasping, automatic production line and unloading

Through the use of composite robots, material transfer automation can be realized between production workshops, machines, and production lines. The composite robot can transport and grab products of various specifications and move between different stations, greatly reducing the production line’s dependence on manual material transportation and loading and unloading.

MiR currently has six AMRs with UR collaborative robotic arms operating at the Sino-German Intelligent Manufacturing Research Institute in Nanjing. These six composite robots cooperate with the processing center in the Sino-German Research Institute and are embedded in its industrial mobile collaborative sorting system to demonstrate and train the links of loading and unloading, transfer and transportation of products.

Top Module, Enhanced Industrial Automation

MiR AMR is extremely open and adaptable. In addition to connecting the robotic arm to form a composite robot, it can also be connected with different top Modules to further enhance its functions and usage scenarios. Through the solution platform MiRGo,

MiR AMRs fit dozens of out-of-the-box solutions, including Nord Modules tray modules.

The MiR AMR with the pallet module can transport the material to the designated point, and then seamlessly connect with the composite robot to complete the fine material grasping action and enhance the automation scene in the industrial field.

MiR currently has seven AMR products with different load levels, ranging from the lightest 100kg to 1,350kg, which can meet the application of multi-industry production lines in all scenarios. With the continuous development of technology, MiR is also constantly exploring the functional boundaries and application scenarios of AMR, including continuing to develop the application of composite robots. In addition, MiR will hold technology sharing activities in Beijing and Shanghai respectively in December, at which time, it will demonstrate the functions of composite robots, and will showcase its new product MiR1350 AMR for the first time in the world.

The Links: BSM200GA120DLCS TPS40131RHBR