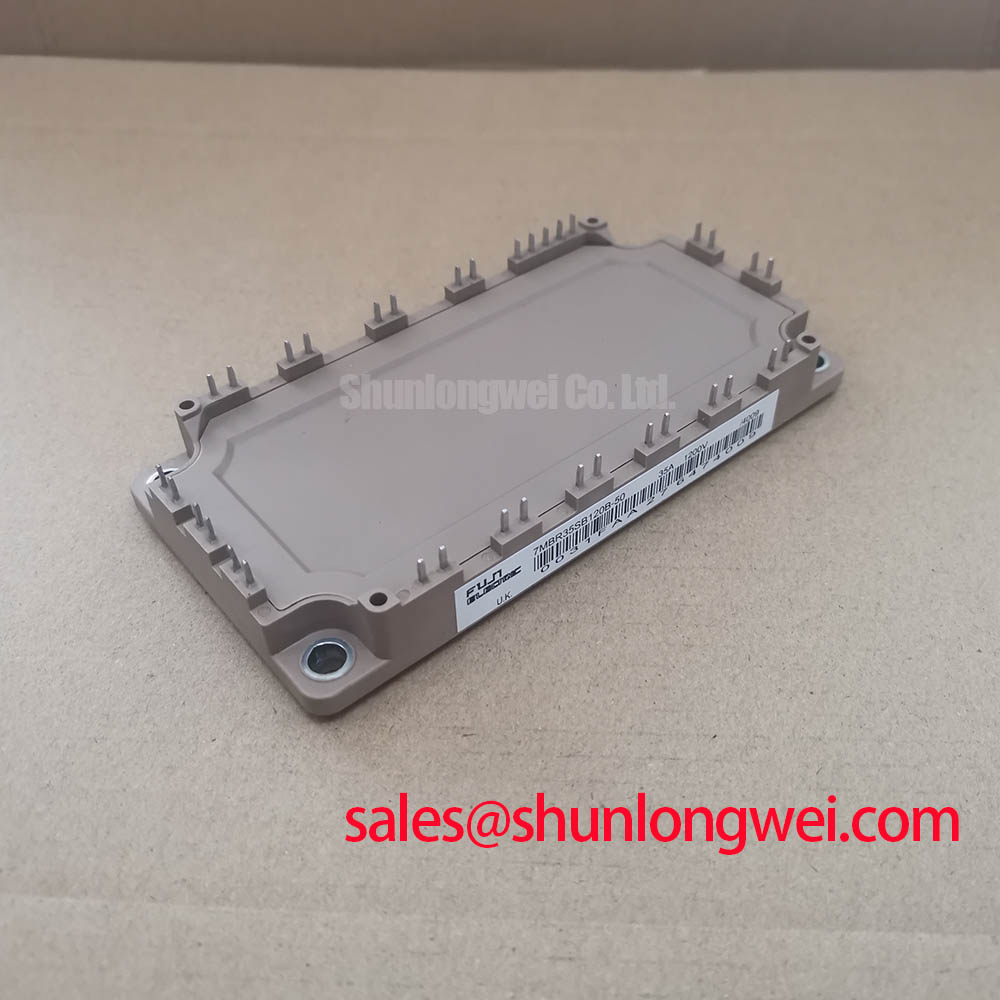

7MBR35SB120B-50: Technical Review of a 1200V/35A PIM IGBT Module

The 7MBR35SB120B-50 is a highly integrated Power Integrated Module (PIM) from Fuji Electric, engineered to optimize the performance and reliability of compact motor drives and power conversion systems. This 7-in-1 module consolidates a three-phase converter bridge, a three-phase inverter, and a dynamic brake circuit into a single package, offering a streamlined solution for system designers. With core specifications of 1200V and 35A, it delivers exceptional thermal efficiency and simplified system integration. Key benefits include reduced conduction losses and enhanced thermal monitoring capabilities. Answering a key engineering question, this module's integrated nature drastically reduces parasitic inductance and simplifies assembly compared to discrete component solutions. For low-to-mid-power motor drives requiring high reliability within a constrained footprint, the 7MBR35SB120B-50 presents a technically robust and efficient power stage solution.

Key Parameter Overview

Content last revised on October 22, 2025.

A Breakdown of Electrical and Thermal Specifications

The performance of the 7MBR35SB120B-50 is defined by its electrical and thermal characteristics, which are critical for system design, simulation, and thermal management. The parameters below are specified at Tj=25°C unless otherwise noted.

| Parameter | Symbol | Condition | Value | Unit |

|---|---|---|---|---|

| Inverter Section | ||||

| Collector-Emitter Voltage | VCES | - | 1200 | V |

| Continuous Collector Current | IC | Tc=80°C | 35 | A |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC=35A, VGE=15V, Tj=125°C | 2.1 (Typ.) | V |

| Thermal Resistance (Junction to Case) | Rth(j-c) | IGBT | 0.59 (Max) | °C/W |

| Converter Section (Diode Bridge) | ||||

| Repetitive Peak Reverse Voltage | VRRM | - | 1600 | V |

| Average Output Current | IO | - | 35 | A |

| Thermistor Section | ||||

| Resistance | R25 | T=25°C | 50 | kΩ |

Download the 7MBR35SB120B-50 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Advantages in Compact Motor Control Systems

The 7MBR35SB120B-50 is engineered for applications where power density, efficiency, and reliability are paramount. Its high level of integration makes it a primary choice for designers of low-to-mid-power (approx. 7.5kW - 15kW) industrial systems.

A high-fidelity engineering scenario for this module is the development of a compact Variable Frequency Drive (VFD) for conveyor belt systems in a logistics facility. The engineering challenge is to house the drive in a sealed, non-ventilated enclosure to protect against dust, which severely restricts thermal management options. The 7MBR35SB120B-50 directly addresses this by combining a low VCE(sat), which minimizes heat generation from conduction losses, with an integrated NTC thermistor. This thermistor provides real-time temperature feedback to the VFD's controller, allowing for intelligent power scaling or shutdown to prevent thermal runaway—a critical feature for maintaining system uptime and longevity in harsh environments. The module's PIM construction also significantly reduces the PCB footprint and assembly complexity, enabling a more compact final product.

For systems that require higher current handling for more demanding motor loads, the related 7MBR50SB120-50 provides a similar 1200V rating with a 50A capacity within the same family.

Frequently Asked Questions (FAQ)

Engineering Inquiries on Implementation and Performance

What is the primary benefit of the integrated NTC thermistor in the 7MBR35SB120B-50?

The integrated NTC thermistor provides a direct, cost-effective method for monitoring the module's internal temperature. This enables the implementation of precise over-temperature protection within the drive's control logic, enhancing system safety and preventing catastrophic failures due to excessive heat. What is the advantage of its high integration level? By combining seven power devices into one package, it significantly improves long-term reliability by reducing solder joints and simplifying thermal design.

How does the 2500V isolation voltage (Viso) impact system design and safety compliance?

The specified 2500V AC isolation for one minute between the terminals and the copper baseplate ensures robust electrical separation between the high-voltage power circuit and the grounded heatsink. This is crucial for meeting safety standards such as those from UL or IEC, simplifying the certification process for the end equipment (e.g., servo drives, UPS) and ensuring operator safety.

Technical Deep Dive

Analyzing the Thermal Path for Enhanced System Longevity

A critical factor in the long-term reliability of any power module is its ability to efficiently evacuate heat from the semiconductor junctions. The 7MBR35SB120B-50 specifies a maximum thermal resistance from junction to case (Rth(j-c)) of 0.59°C/W for the inverter IGBTs. This parameter is more than just a number; it dictates the entire thermal design of the system.

Think of thermal resistance as the width of a pipe for heat to flow through. A lower Rth(j-c) value, like the one in this module, represents a very wide, unobstructed pipe. This allows the heat generated during switching and conduction to travel quickly and easily from the silicon chip to the module's baseplate. This efficiency has two direct engineering benefits: for a given power loss, the junction temperature will be lower, extending the module's operational life. Alternatively, it allows engineers to design a more compact and cost-effective cooling system (heatsink) while maintaining the same target junction temperature, directly supporting the goal of increasing power density. This effective thermal management is fundamental to the module's value proposition in space-constrained industrial applications. For more insights into optimizing thermal performance, explore this guide on mastering IGBT thermal management.

Request for Quotation

To evaluate the 7MBR35SB120B-50 for your power conversion or motor drive application, please contact our technical sales team. We provide engineering-level support to help you assess component suitability based on official documentation from the manufacturer, Fuji Electric. Submit your inquiry to receive detailed information and to discuss your project requirements.