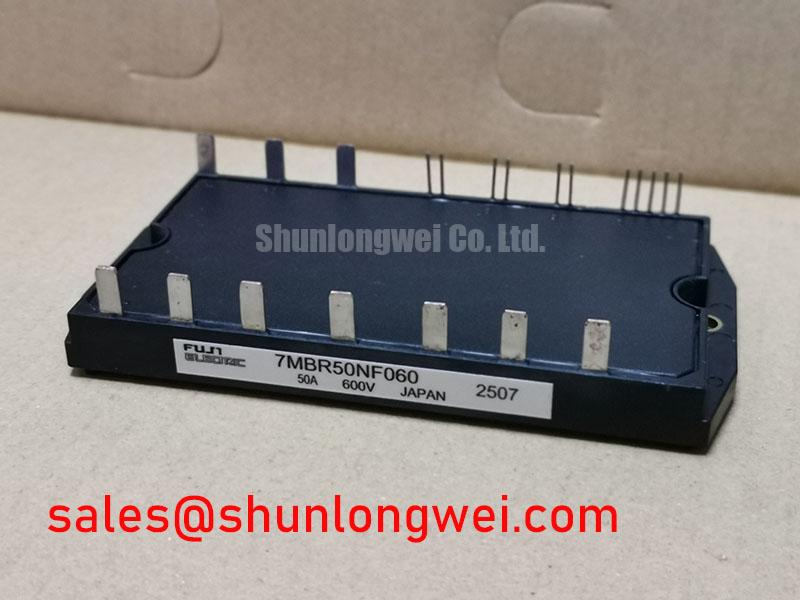

Fuji 7MBR50NF-060 IGBT Module: Datasheet & Specs Review

An integrated 7-in-1 IGBT module engineered to simplify power stage design and reduce assembly complexity in compact motor drives.

The Fuji Electric 7MBR50NF-060 is a Power Integrated Module (PIM) providing a comprehensive solution for low-power motor control. It consolidates a three-phase inverter, a converter diode bridge, and a dynamic brake circuit into a single, compact package rated for 600V and 50A. This level of integration directly addresses the engineering need to reduce physical footprint and streamline the manufacturing process. By combining seven power stages, the module minimizes external component count, which simplifies both the PCB layout and the overall thermal management architecture. What is the key benefit of the 7-in-1 topology? It significantly reduces component count and simplifies PCB layout.

Application Scenarios & Value

Leveraging Integrated Functionality in Compact Power Systems

The 7MBR50NF-060 is specified for applications where space, assembly efficiency, and reliability are primary design drivers. Its architecture provides a robust foundation for various power conversion systems.

- Compact Variable Frequency Drives (VFDs): In systems for conveyors, pumps, and HVAC, the all-in-one design accelerates development. The integrated brake chopper is essential for managing deceleration and regenerative energy, a frequent requirement in dynamic motor applications.

- AC and DC Servo Drive Amplifiers: The module's low inductance and integrated nature support the precise control needed in robotics and automated systems. A low collector-emitter saturation voltage (VCE(sat)) reduces conduction losses, improving thermal performance in space-constrained control cabinets.

- Uninterruptible Power Supplies (UPS): For small to medium UPS systems, the 7MBR50NF-060 offers a pre-validated power core that simplifies the design and enhances system reliability by minimizing interconnections.

For low-power motor drives operating below 15 kHz, the 7MBR50NF-060's typical VCE(sat) of 1.8V makes it a sound choice for simplifying thermal management requirements.

Industry Insights & Strategic Advantage

Meeting the Demands of Modern Automation with Integrated Power Stages

The trend towards distributed and compact automation systems places a premium on power density and design simplicity. The 7MBR50NF-060 aligns directly with this industry vector. Consolidating multiple power stages into one module, like in this IGBT for robotic servo drives, not only shrinks the final product size but also de-risks the design process. Engineers can bypass the complex task of matching and laying out discrete components, reducing parasitic inductance and optimizing thermal pathways from the outset. This pre-integrated approach shortens time-to-market, a crucial advantage in the competitive industrial equipment landscape.

Key Parameter Overview

Data-Driven Insights for System Designers

The technical specifications of the 7MBR50NF-060 are foundational to its application. Understanding these parameters is key to leveraging the module's full potential while ensuring system reliability.

One of the most critical parameters is the thermal resistance (Rth(j-c)). This value represents how effectively heat can be transferred from the active semiconductor junction to the module's case. Think of it as the bottleneck in a pipe; a lower thermal resistance is like a wider pipe, allowing more heat to escape efficiently. A low Rth(j-c) simplifies heatsink selection and can lead to a more compact and cost-effective thermal solution.

Another key metric is the Collector-Emitter Saturation Voltage (VCE(sat)). This defines the voltage drop across the IGBT when it is fully turned on, directly impacting conduction losses. Lower VCE(sat) means less power is wasted as heat during operation, which improves overall system efficiency and further eases thermal design constraints.

| Parameter | Symbol | Conditions | Value |

|---|---|---|---|

| Inverter Stage | |||

| Collector-Emitter Voltage | VCES | 600V | |

| Collector Current (DC) | IC | Tc=80°C | 50A |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC=50A, VGE=15V | 1.8V (Typ) / 2.2V (Max) |

| Brake Stage | |||

| Collector-Emitter Voltage | VCES | 600V | |

| Collector Current (DC) | IC | Tc=80°C | 25A |

| Converter Stage | |||

| Repetitive Peak Reverse Voltage | VRRM | 800V | |

| Average Output Current | Io | 50A | |

| Thermal Characteristics | |||

| Operating Junction Temperature | Tj | +150°C | |

| Isolation Voltage | Viso | AC, 1 minute | 2500V |

Download the Datasheet for 7MBR50NF-060

Technical Deep Dive

Anatomy of a High-Integration Power Module

The architecture of the 7MBR50NF-060 from Fuji Electric is a strategic choice for system simplification. By co-packaging the input three-phase diode rectifier, the output three-phase IGBT inverter, and the brake chopper IGBT, the module provides a nearly complete power stage. What is the effect of minimized internal wiring? Reduced stray inductance, which lowers voltage overshoot during switching and improves EMC performance. This integration means engineers can focus on the control logic and external interfaces, rather than the intricacies of power component layout. The module also includes an NTC thermistor for direct temperature feedback, simplifying the implementation of thermal protection schemes and enhancing long-term operational safety.

Frequently Asked Questions (FAQ)

How does the integrated brake chopper in the 7MBR50NF-060 benefit motor drive applications?

The integrated brake chopper provides a built-in circuit to safely dissipate regenerative energy from a decelerating motor. This prevents the DC bus voltage from rising to dangerous levels, protecting other components. By integrating this function, the 7MBR50NF-060 eliminates the need for an external braking unit, saving space, reducing wiring complexity, and simplifying the bill of materials for the drive system.

Can the 7MBR50NF-060 be used if the brake function is not required?

Yes. If the dynamic braking functionality is not needed for a specific application, the brake chopper section can be left unused. The gate and emitter terminals of the brake IGBT should be shorted to ensure it remains in a safe, off-state. This allows the module to function as a standard 6-in-1 inverter with an integrated converter, providing design flexibility.

Forward-Looking Engineering

For engineers and procurement managers evaluating power solutions, the Fuji Electric 7MBR50NF-060 presents a compelling case for design simplification. By adopting an integrated module, development teams can significantly reduce the design cycle and assembly costs associated with discrete solutions. As systems in industrial automation and power conversion continue to demand smaller footprints and higher reliability, the strategic value of integrated modules like the 7MBR50NF-060 becomes increasingly evident. The decision to use this module is a step toward more streamlined, cost-effective, and robust power electronic designs. For systems requiring different power levels, the related 7MBR50SA060 offers similar integration in a different series.