Sharp LQ10D363: Technical Review of a Robust 10.4-inch Industrial TFT-LCD Module

An Engineering-Focused Analysis of the LQ10D363 Display

Content last revised on October 14, 2025.

The Sharp LQ10D363 is an industrially-hardened 10.4-inch VGA display engineered for long-term reliability in harsh thermal environments and seamless integration into legacy systems. This color active matrix TFT-LCD module delivers a specification-driven solution for demanding operational contexts. Key performance metrics include a 10.4-inch diagonal screen, 640x480 VGA resolution, 350 cd/m² brightness, and a -10°C to +70°C operating temperature range. The design provides two primary engineering benefits: exceptional thermal resilience and straightforward legacy system compatibility. It directly addresses the need for a durable, drop-in replacement for aging control panels in industrial machinery. For legacy industrial HMIs requiring a thermally robust and direct-fit VGA replacement, the LQ10D363 is a benchmark for reliability.

Key Parameter Overview

Decoding the Specs for Environmental Resilience and Visual Performance

The technical specifications of the Sharp LQ10D363 are foundational to its performance in industrial settings. Each parameter is a critical factor in the design and integration process for engineers and system architects.

| Parameter | Specification | Engineering Implication |

| Display Size | 10.4 inch (26 cm) diagonal | Standardized form factor for a wide range of industrial panel cutouts. |

| Resolution | 640(H) × 480(V) pixels (VGA) | Ensures compatibility with a vast installed base of industrial software and controllers. |

| Luminance (Brightness) | 350 cd/m² (Typical) | Provides clear readability in typical indoor industrial lighting conditions. |

| Contrast Ratio | 300:1 (Typical) | Delivers distinct separation between light and dark elements for clear data visualization. |

| Operating Temperature | -10°C to +70°C | Guarantees operational stability in non-climate-controlled environments, from cold starts to high-heat processes. |

| Storage Temperature | -30°C to +80°C | High resilience against extreme temperature swings during transport or storage. |

| Backlight System | 1 CCFL with external inverter requirement | Offers design flexibility in selecting a driving circuit tailored to specific system power and EMI constraints. |

| Surface Treatment | Anti-glare, Hard coating (3H) | Minimizes distracting reflections and resists surface scratches in high-traffic areas. |

Application Scenarios & Value

System-Level Benefits in Industrial Equipment Modernization

The LQ10D363 is engineered for environments where reliability and long-term availability are paramount. Its value is most evident in the maintenance, repair, and overhaul (MRO) of capital-intensive equipment. What is the primary benefit of its wide operating temperature? Reliable performance in thermally demanding industrial environments.

Consider a common engineering challenge: retrofitting the operator console of a 15-year-old CNC machine. The original CRT or early-generation LCD has failed, and a replacement must integrate seamlessly without extensive rework. The LQ10D363's standard 10.4-inch VGA format provides a direct mechanical and electrical fit. Its wide operating temperature range of -10°C to +70°C is critical, as the machine enclosure may lack active cooling and be subject to significant temperature fluctuations on the factory floor. The 350 cd/m² brightness ensures the user interface remains legible under variable overhead lighting, directly impacting operator efficiency and reducing errors. This module provides a cost-effective path to extending the productive life of existing industrial automation assets. While this module is optimized for VGA systems, for applications requiring a smaller footprint, the related G084SN05 V9 offers an 8.4-inch alternative.

Frequently Asked Questions (FAQ)

Engineering Inquiries on the LQ10D363

How does the -10°C to +70°C operating temperature range directly impact system design?

This wide range reduces the need for complex and costly thermal management systems, such as heaters or high-power fans, within an equipment enclosure. It allows the display to be deployed in environments where temperature is not precisely controlled, enhancing the overall robustness and lowering the total cost of ownership of the end system.

What is the significance of the 350 cd/m² brightness for a typical Human Machine Interface (HMI)?

A brightness of 350 candelas per square meter (cd/m²) provides strong visibility for indoor industrial environments with fluorescent or mixed lighting. To understand this value, think of it as being significantly brighter than a typical office monitor. This level of luminance is a key factor in ensuring that critical process data displayed on an HMI is always clear and unambiguous for the operator, which is essential for both productivity and safety.

Does the LQ10D363 require an external backlight inverter?

Yes, the datasheet confirms that the CCFL backlight requires an external DC/AC inverter. While this means an additional component is necessary, it provides engineers with the flexibility to select an inverter that best matches their system's power supply voltage, EMI/EMC requirements, and desired dimming control capabilities.

What makes the 10.4-inch VGA format a strategic choice for system maintenance and upgrades?

The 10.4-inch diagonal size and 640x480 VGA resolution represent a long-standing de facto standard in industrial control panels. Selecting a display with these specifications, like the LQ10D363, minimizes mechanical and software integration challenges when replacing failed units in the field. This simplifies the supply chain for spare parts and reduces equipment downtime during repairs.

Technical Deep Dive

Analyzing the Impact of CCFL and Surface Treatment on Reliability

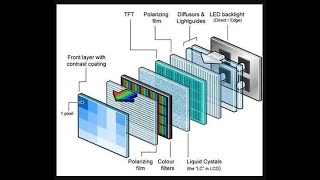

While newer LED backlights are common, the Cold Cathode Fluorescent Lamp (CCFL) technology in the LQ10D363 offers a known and highly stable performance profile essential for industrial reliability. CCFLs have a well-documented behavior across wide temperature ranges, ensuring consistent brightness and color rendering, which is critical for process control applications where color-coded alerts are used. This predictability is a key reason for its continued use in systems demanding long operational lifetimes.

Furthermore, the specified anti-glare (AG) surface treatment is a critical feature for usability. The AG coating functions much like a frosted glass window, diffusing incident light rather than reflecting it directly back at the operator. This microscopic etching of the surface scatters ambient light, significantly reducing specular reflections from overhead lights or nearby windows. For an engineer designing an operator panel, this means better ergonomics, reduced eye strain, and fewer errors caused by misreading a display obscured by glare, a common issue in dynamic factory environments. Combined with a hard coating, the surface is also protected against the physical wear common in industrial use.

The strategic value of the LQ10D363 lies in its precise alignment with the needs of long-lifecycle industrial systems. By providing a robust, reliable display with a standard interface, it enables the continued operation and modernization of essential machinery, protecting capital investment and ensuring operational continuity. Its design philosophy prioritizes stability and compatibility over featuring the latest display innovations, making it a calculated choice for engineers focused on system longevity and maintainability. For further reading on display technologies, see this resource on Industrial vs. Consumer Displays and information from leading manufacturers like Sharp.