The power level of power electronic devices can be increased by connecting power electronic components in series or parallel. This is particularly advantageous in designing high-power converters, offering simple structures and low costs. By connecting IGBT (Insulated Gate Bipolar Transistor) in parallel, the current rating of the converter can be significantly increased, thereby enhancing the overall power density, making it cost-effective.

Analysis of Parallel Operation of IGBT

- Factors Affecting Current Sharing in Parallel IGBTs

a. Static Parameters of IGBT and Anti-parallel Diode: – The saturation voltage drop of the IGBT (Vce(sat)) and the forward voltage drop of the anti-parallel diode (Vf) primarily affect static current sharing. – The transconductance of the IGBT (gfs), gate-emitter threshold voltage (Vge_th), and the reverse recovery characteristics of the anti-parallel diode (such as reverse recovery time trr and reverse recovery charge Qrr) mainly affect dynamic current sharing.

b. Driver Circuit Parameters: – The gate drive voltage (Vge) of parallel IGBTs affects static current sharing. – The rate of change of the gate drive signal, gate drive resistance (Rg), and the layout and inductance of the drive circuit significantly affect dynamic current sharing.

c. Thermal Considerations: – Uneven cooling of IGBTs can lead to temperature differences, impacting their temperature characteristics and creating a positive feedback effect, affecting current sharing.

d. Main Circuit Structure: – Differences in line inductance caused by the main circuit structure affect dynamic current sharing. – Line resistance affects static current sharing.

- Principles of Parallel Technology

a. Module Selection: – Select IGBT units with positive temperature coefficients, preferably from the same batch, to improve device parameter consistency and achieve optimal static current sharing.

b. Shared Drive Circuit: – Through rational design of IGBT drive circuit parameters and sharing the same drive circuit, the switching speed of the IGBTs can be improved, reducing the impact of device parameter distribution and enhancing dynamic current sharing.

c. Symmetrical Layout: – Ensure that all power loops and drive loops in the parallel circuit have minimal loop inductance and maintain strict symmetrical layout. Modules should be placed as close as possible, optimizing balanced cooling to enhance the current sharing effect of parallel IGBTs.

d. Series Current Sharing Inductor: – The inductance connected in series at the AC output end can suppress the current change rate of IGBT and diode during the switching process, greatly reducing current imbalance caused by switching process differences. Proper design of the current sharing inductor ensures the dynamic current sharing effect of parallel IGBTs meets design requirements.

e. Derating Use: – Even if the selection of IGBT modules, shared drive circuit, and optimized layout are at their best, static and dynamic performance cannot reach ideal balance. It is advisable to derate IGBT usage by 15%-20%.

Practical Application and Design Example

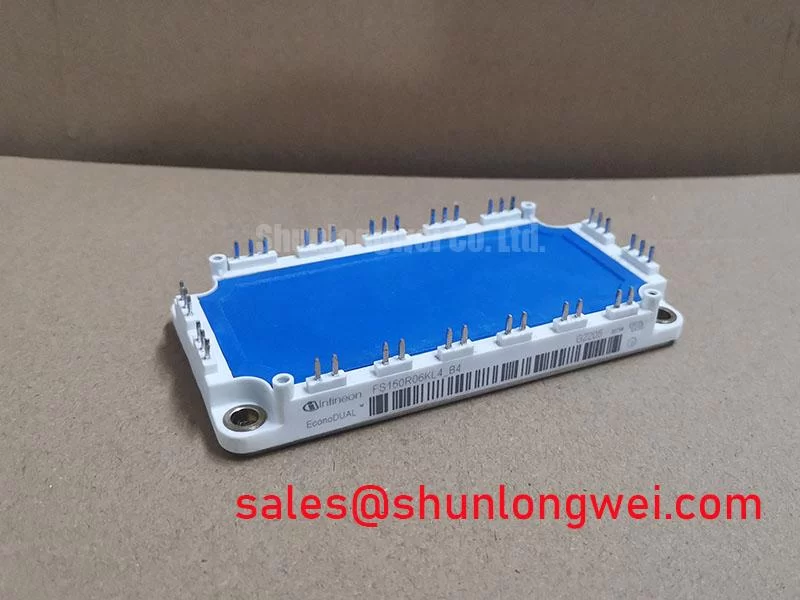

A 250kVA rated circuit is designed with a three-phase AC output line voltage of 380V and an AC output phase current of 380A. Each phase half-bridge circuit consists of three parallel IGBT half-bridge circuits, connected through current sharing inductors to enhance dynamic current sharing. The IGBT modules are connected to the DC support capacitor via a composite busbar, reducing overvoltage during the switching process and lowering electromagnetic interference, thereby improving electromagnetic compatibility (EMC) of the circuit.

IGBT Parameter Selection Method

- Saturation Voltage Drop Test:

- Test the saturation voltage drop (Vsat) of IGBTs to ensure parameter consistency within 100mV.

- Built-in Diode Saturation Voltage Drop Test:

- Test the saturation voltage drop of the built-in diode of IGBTs to ensure consistent temperature rise during static current.

- Built-in Diode Reverse Recovery Time Test:

- Test the reverse recovery time of the built-in diode to determine its speed and ensure it meets the requirements for parallel connection.

Experimental Results and Analysis

The experiment demonstrates that the hardware system design is reasonable, the control system operates normally, and the system can run stably at 250kVA capacity.

Conclusion

Through theoretical research and experimental verification, a high-efficiency, reliable 250kVA circuit is designed. Its compact structure, independent function, and low cost have high application value. By using parallel IGBT technology, higher power levels can be achieved while maintaining system stability and reliability.