Content last revised on February 7, 2026

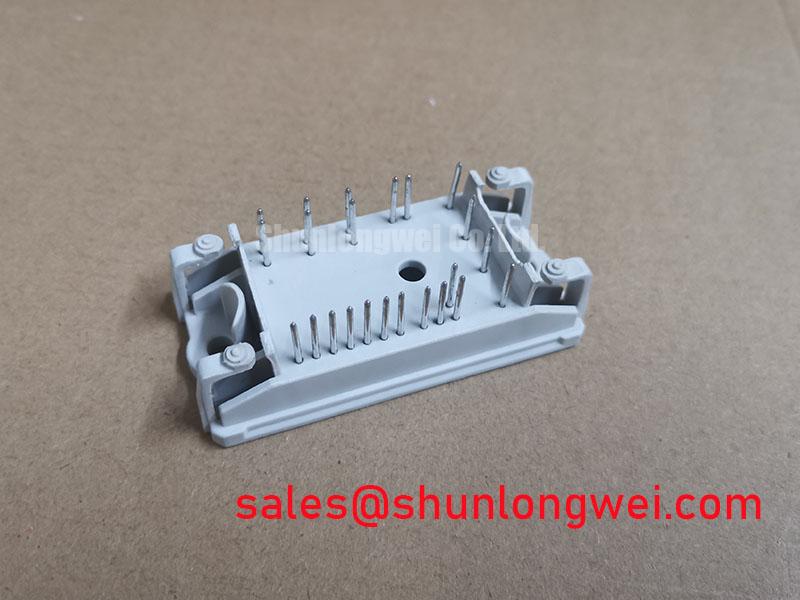

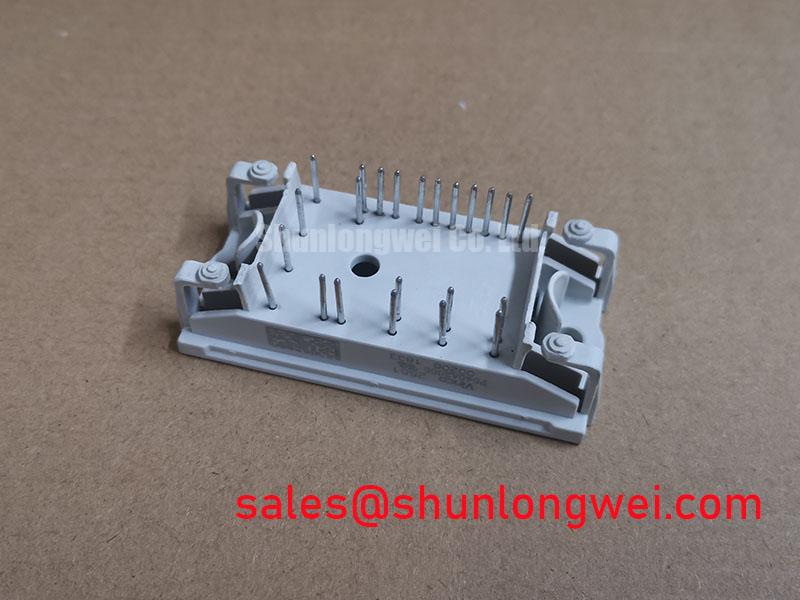

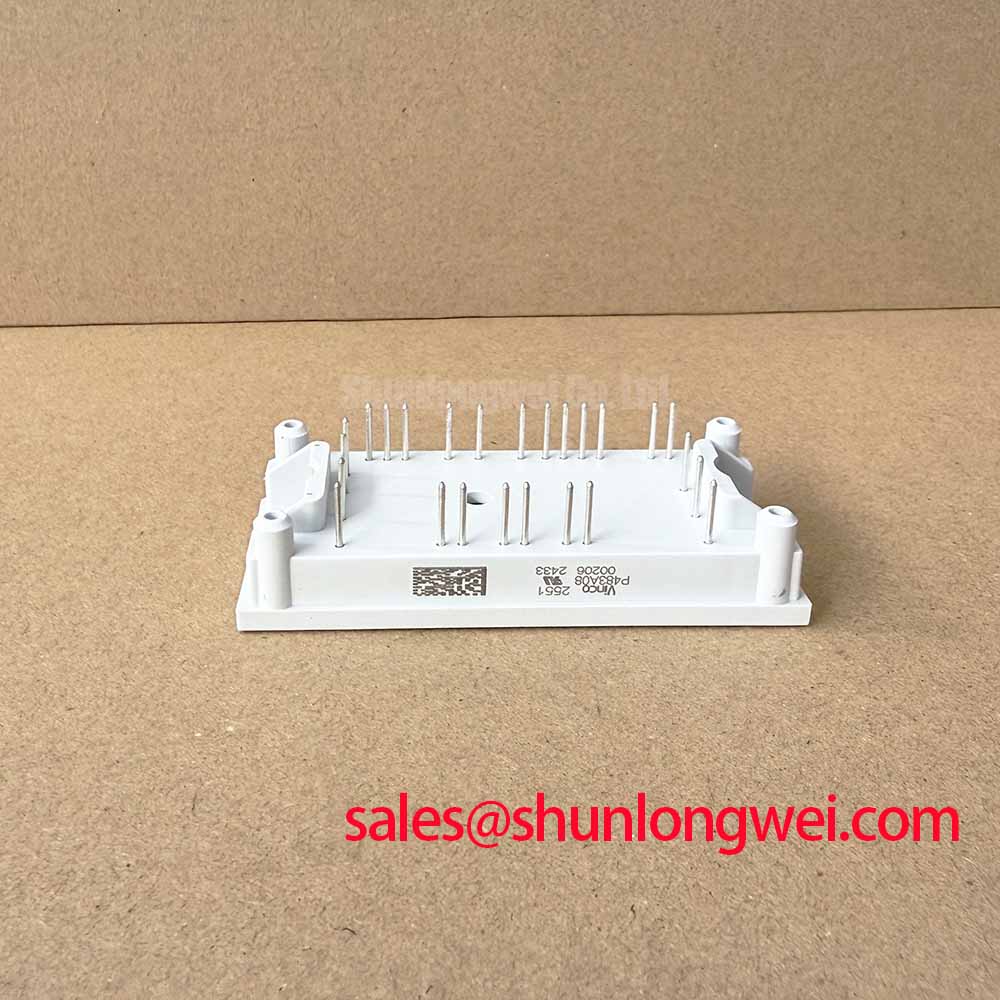

P546A2005 Tyco Electronics 1200V IGBT Power Integrated Module

The P546A2005 is a high-performance Power Integrated Module (PIM) from Tyco Electronics, designed to consolidate the input rectifier, inverter stage, and brake chopper into a single, thermally efficient housing. This 1200V | 35A module is engineered to maximize power density in industrial motor control applications while minimizing the parasitic inductance typically associated with discrete component layouts. By integrating multiple power stages, the P546A2005 provides a robust solution for engineers seeking to reduce system footprint without compromising electrical isolation or switching efficiency. For mid-range motor drives where board space is at a premium, this 1200V integrated module offers the most efficient path to reduced footprint.

Application Scenarios & Value

Achieving System-Level Footprint Reduction in Industrial Motor Controllers

Engineers often face the daunting challenge of managing thermal dissipation and electromagnetic interference (EMI) within increasingly cramped industrial control cabinets. The P546A2005 addresses this by centralizing the heat-generating components of a Variable Frequency Drive (VFD) onto a single isolated baseplate. In a high-fidelity engineering scenario, such as an automated conveyor system, the P546A2005 allows for the removal of multiple discrete heat sinks and complex busbar arrangements. Its integrated brake chopper stage is particularly critical for handling regenerative energy during rapid deceleration of heavy loads, preventing overvoltage trips in the DC link.

How does the P546A2005 simplify drive design? It eliminates the need for complex inter-stage wiring, significantly lowering the risk of assembly errors and enhancing long-term reliability against mechanical vibration. While this model is ideal for 1200V systems requiring moderate current handling, for designs needing higher capacity, the related FS50R12KE3 offers a 50A rating. Integrating this module into a UPS or solar inverter system ensures a streamlined assembly process and a more predictable thermal profile under variable PWM frequency loads.

Technical Deep Dive

Optimizing Switching Efficiency Through Low-Inductance Integrated Topology

The core architectural advantage of the P546A2005 lies in its internal layout, which utilizes an NPT (Non-Punch-Through) or Trench-gate IGBT structure (depending on the specific die generation) to balance low VCE(sat) with high short-circuit ruggedness. Think of the P546A2005 as a well-planned integrated highway interchange; whereas discrete components act like local stoplights that cause congestion (parasitic inductance), the PIM architecture allows current to flow between stages with minimal impedance. This reduces voltage overshoots during high-speed switching transitions, thereby protecting the gate oxide and extending the module's operational lifespan.

From a Thermal Management perspective, the module's internal isolation between the power chips and the copper baseplate is optimized for a low Thermal Resistance (Rth). This integration is akin to a compact multi-tool compared to a bag of individual wrenches; it provides exactly what is needed in a more manageable form factor. By reducing the number of external connections, the P546A2005 minimizes the "antenna effect," which often plagues discrete designs, making it easier to comply with strict IEC 61800-3 EMI standards. Engineers can further explore the trade-offs of this technology in our guide on IGBT vs. MOSFET vs. BJT selection.

Key Parameter Overview

Decoding Specs for High-Density Power Conversion

| Critical Metric | Rated Value / Specification | Engineering Significance |

|---|---|---|

| Collector-Emitter Voltage (Vces) | 1200V | Provides necessary headroom for 400V-480VAC grid systems. |

| Continuous Collector Current (Ic) | 35A (at Tc=25°C) | Determines maximum motor horsepower rating (approx. 5.5-7.5kW). |

| Saturation Voltage (Vce(sat)) | Typ. 2.1V | Directly influences conduction losses and cooling requirements. |

| Integration Topology | CIB (Converter-Inverter-Brake) | Replaces up to 13 discrete power components in a single module. |

| Isolation Voltage (Visol) | 2500V AC (1 min) | Ensures safety and compliance with international industrial standards. |

Download the P546A2005 datasheet for detailed specifications and performance curves: Request Technical Documentation.

Frequently Asked Questions

What is the primary benefit of the P546A2005 integrated brake chopper?

The integrated brake chopper allows the system to dissipate regenerative energy through an external resistor during motor braking, which simplifies the protection of the DC bus in Variable Frequency Drive (VFD) applications.

How does the Vce(sat) of 2.1V impact the cooling system design?

A lower Vce(sat) reduces conduction losses. With a typical value of 2.1V, the P546A2005 allows for smaller heat sinks compared to older Darlington modules, facilitating higher power density in the inverter stage.

Can the P546A2005 be used for 690V industrial line applications?

No, the 1200V rating is specifically intended for 400V-480V mains. For 690V systems, a module with a Vces of 1700V would be required to maintain a safe operating margin against transient overvoltages.

How does the module's thermal resistance (Rth) influence long-term reliability?

Low thermal resistance ensures that the junction temperature (Tj) remains well below the maximum limit during peak loads. This prevents thermal cycling fatigue, which is a common failure mode in heavy industrial machinery. For more on this, see our article on why Rth matters.

The strategic adoption of the P546A2005 reflects a shift toward highly integrated power stages that balance cost-efficiency with engineering precision. As industrial systems move toward more compact and modular designs, the ability to rely on a single, verified PIM housing becomes a competitive advantage for OEM designers. For a broader understanding of how these modules are evolving, explore the future role of IGBTs in power electronics. To support lower-power auxiliary drives, the FP25R12KE3 provides a complementary solution for 25A requirements within the same voltage class.