The electric vehicle (EV) revolution is accelerating, but two persistent roadblocks remain for mass adoption: range anxiety and charging time. While battery capacity is steadily increasing, the time spent tethered to a charging station is a major pain point for consumers. The industry’s definitive answer is the 800V high-voltage platform, promising to add hundreds of miles of range in the time it takes to grab a coffee. However, this leap in performance creates immense pressure on the power electronics that make it possible. At the heart of the ultra-fast DC charger lies the Insulated Gate Bipolar Transistor (IGBT) module, and the shift to 800V architectures demands a new class of more robust, efficient, and thermally resilient IGBTs.

For engineers and procurement managers designing or sourcing for next-generation charging infrastructure, understanding this shift is not just academic—it’s critical for project success, system reliability, and long-term ROI. The question is no longer *if* 800V systems will dominate, but *how* to select the components that can withstand the extreme electrical and thermal stresses involved.

The Physics of Fast Charging: Why Voltage is King (P = V x I)

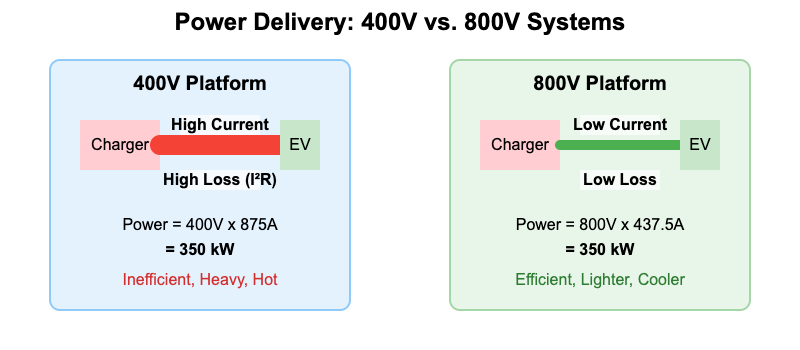

To appreciate the challenge for IGBTs, we must first revisit a fundamental law of electricity: Power (P) equals Voltage (V) multiplied by Current (I). To charge a battery faster, you need to deliver more power (measured in kilowatts, kW). For years, the industry standard has been 400V platforms. To achieve higher power on these systems, manufacturers had to significantly increase the current.

This “high-current” approach has serious drawbacks:

- Excessive Heat Generation: Power loss due to resistance in cables and components is calculated as I²R (current squared times resistance). Doubling the current quadruples the heat loss. This waste heat reduces efficiency and puts enormous thermal strain on all components, especially the power-switching semiconductors.

- Bulky and Expensive Cabling: To safely handle hundreds of amps, charging cables must be thick, heavy, and often liquid-cooled. This increases the cost, reduces usability, and creates a potential point of failure.

- Component Stress: Every component in the power path, from connectors to busbars and the IGBTs themselves, must be oversized to handle the high current, increasing the overall system cost and footprint.

By doubling the system voltage to 800V, engineers can deliver the same amount of power with half the current. For example, delivering 350kW of power:

- On a 400V system (practical max ~437.5A): P = 400V * 875A (The current is extremely high, practically unfeasible for continuous charging, so let’s use a more realistic 350kW target at a slightly higher voltage). To get 350kW at, say, 500V, you’d need 700A. At 400V, you’d need 875A.

- On an 800V system (practical ~437.5A): P = 800V * 437.5A.

The reduction in current from over 800A to under 450A is transformative. It dramatically reduces I²R losses, allowing for thinner, lighter, and cheaper cables, and most importantly, it fundamentally changes the operating conditions for the power electronics inside the DC fast charger.

The Unsung Hero: The IGBT Module in the 800V DC Fast Charger

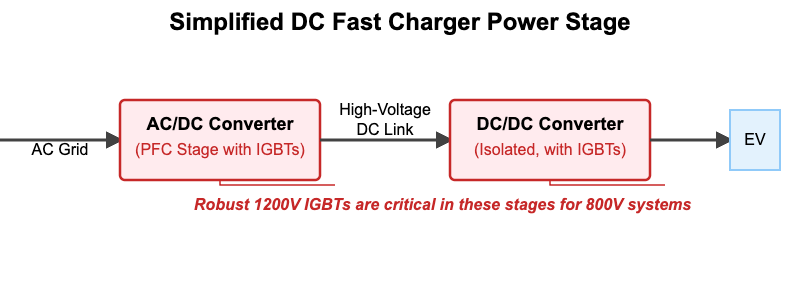

The off-board DC fast charger is where the magic happens. It takes AC power from the grid, converts it to high-voltage DC, and then precisely controls the flow of that DC power into the vehicle’s battery. This process involves two key power conversion stages: an AC/DC rectifier and a DC/DC converter. IGBT modules are the workhorses in both stages, switching on and off thousands of times per second to manage these immense power flows.

In an 800V architecture, these IGBTs face a far more hostile environment. The requirements are no longer incremental; they represent a significant step-change in performance demand.

Challenge 1: The Need for 1200V Blocking Voltage

This is a point that often confuses newcomers. Why does an 800V system require IGBTs rated for 1200V? The 800V is the *nominal* system voltage. In a real-world power-switching circuit, high-frequency switching (especially during turn-off) combined with stray inductance in the circuit layout creates significant voltage spikes, or “overshoot.”

A robust design requires a substantial safety margin to prevent these spikes from exceeding the IGBT’s breakdown voltage (V_CES). If the peak voltage exceeds this rating, the device will avalanche, leading to catastrophic failure. A 1200V-rated IGBT provides the necessary headroom to reliably and safely operate on an 800V DC bus, ensuring long-term operational stability.

Challenge 2: Extreme Power Density and Thermal Stress

Charger manufacturers are constantly pushing to make their units smaller, lighter, and cheaper. A 350kW or 500kW charger today might occupy the same physical footprint as a 150kW unit from a few years ago. This means the power density has more than doubled. Consequently, the amount of waste heat generated in a confined space has also skyrocketed.

The IGBT module is the primary source of this heat. It must be ableto dissipate this thermal energy efficiently to keep its junction temperature (T_vj) below the maximum limit (typically 150°C or 175°C). Exceeding this limit degrades the device, shortens its lifespan, and can lead to thermal runaway and failure. This makes the thermal performance of the IGBT module a paramount concern.

Selecting the Right IGBT for 800V Architectures: Key Parameter Deep Dive

When selecting an IGBT module for a high-power, 800V fast charger, engineers must look beyond the headline voltage and current ratings. A nuanced understanding of datasheet parameters is essential for designing a reliable and efficient system. The ideal IGBT for this application, such as the high-performance FS450R12KE3, is a masterpiece of trade-offs.

Here’s a comparative look at the critical parameters:

| Parameter | Importance in 800V Fast Charging | What to Look For |

|---|---|---|

| V_CE(sat) (Collector-Emitter Saturation Voltage) | Determines conduction losses when the IGBT is on. Since the charger delivers high current for extended periods, this is a major source of heat. | The lowest possible value at the operating current and temperature. A difference of even 0.2V can translate to hundreds of watts of extra heat. |

| E_on / E_off (Switching Energy) | Determines switching losses. In high-frequency DC/DC converters, these losses can be even more significant than conduction losses. | A balance is key. Very low switching losses often come at the cost of higher V_CE(sat). Look for IGBTs with advanced trench-gate and field-stop technologies that optimize this trade-off. |

| R_th(j-c) (Thermal Resistance, Junction-to-Case) | Measures how effectively heat can travel from the silicon chip to the module’s baseplate. It is the single most important parameter for thermal management. | An extremely low value. This is heavily influenced by package technology (e.g., AlN substrates, silver sintering) and indicates a superior module design. |

| Short-Circuit Withstand Time (t_SC) | A critical safety and robustness metric. It defines how long the IGBT can survive a direct short-circuit event before failing, allowing time for protection circuits to trip. | Typically 8-10 microseconds (μs). A robust rating provides a larger safety window for the system. |

| Package Technology | The physical construction of the module impacts thermal performance, reliability, and stray inductance. Power cycling (heating/cooling) can cause material fatigue. | Look for enhanced packages with copper baseplates, advanced substrate materials (AlN), and low-inductance internal layouts. Modules like the SKM400GAR12T4 showcase how package innovation leads to superior field reliability. |

Case Study: Upgrading a 150kW Charger to a 350kW, 800V System

Problem: A European charging network operator faced declining utilization of their 150kW/400V chargers as newer EVs with 800V capability entered the market. Their goal was to develop a new 350kW charger that could service both 400V and 800V vehicles, targeting a 10-80% charge time of under 20 minutes for flagship EV models.

Solution: Their engineering team redesigned the power stage from the ground up. They replaced their previous 750V IGBTs with high-performance 1200V IGBT modules designed specifically for high-power applications. The selection criteria focused heavily on a low V_CE(sat) and a market-leading R_th(j-c) to manage the massive thermal load within the new, more compact enclosure. The chosen module featured an enhanced copper baseplate and an optimized internal layout to minimize both thermal resistance and stray inductance.

Result: The new 350kW chargers were a success. Field tests on a popular 800V EV model showed a consistent 10-80% charge time of 18-19 minutes. More impressively, thermal analysis during continuous full-power operation showed the IGBT case temperature stabilizing at 85°C, a full 20°C below their design’s maximum warning limit. This thermal headroom directly translates to a significantly higher Mean Time Between Failures (MTBF) and lower service costs over the charger’s 10-year projected lifespan.

Future Outlook: IGBTs, SiC, and the Road Ahead

No discussion of high-voltage power electronics is complete without mentioning Silicon Carbide (SiC). SiC MOSFETs offer clear advantages in switching speed and lower losses, making them an excellent choice, particularly within the EV’s onboard charger and traction inverter. However, for ultra-high-power off-board DC fast chargers (350kW and above), the decision is more complex.

Advanced 1200V IGBT modules still hold a powerful position. They are a mature, highly reliable technology with a robust supply chain. For pure power-handling capability and cost-effectiveness at these extreme power levels, IGBTs often provide a better overall value proposition. The latest generation of IGBTs has narrowed the performance gap, offering excellent efficiency and unparalleled ruggedness.

The future will likely see a hybrid approach, with both technologies being used where they make the most sense. But for the engineers designing the backbone of our global ultra-fast charging network today, high-performance 1200V IGBTs remain the proven, reliable, and powerful choice.

Conclusion: The Power to Charge Forward

The transition to 800V platforms is the single most important enabler of ultra-fast EV charging. This shift, however, places unprecedented demands on the power conversion electronics that form the heart of DC chargers. It elevates the role of the IGBT module from a simple component to the cornerstone of system performance and reliability.

Engineers must now specify 1200V IGBTs that not only handle the higher voltage but are also optimized for extreme thermal loads and demanding switching cycles. Focusing on key parameters like V_CE(sat), R_th(j-c), and robust package technology is essential. Choosing the right IGBT is a strategic decision that directly impacts charger efficiency, longevity, and the end-user experience.

Navigating the vast landscape of power modules can be daunting. For expert guidance on selecting the ideal 1200V IGBT module for your next-generation fast charger design, we invite you to contact our technical support team. Or, browse our extensive inventory of high-performance IGBT modules to find the right fit for your application.

* SAE J1772 standard for DC fast charging

* Thermal management techniques for power electronics