Content last revised on February 1, 2026

SKM400GAR12T4: High-Speed 1200V IGBT for Demanding Power Conversion Systems

M2. Introduction & Core Strengths

Engineered for High-Frequency and Robust Performance

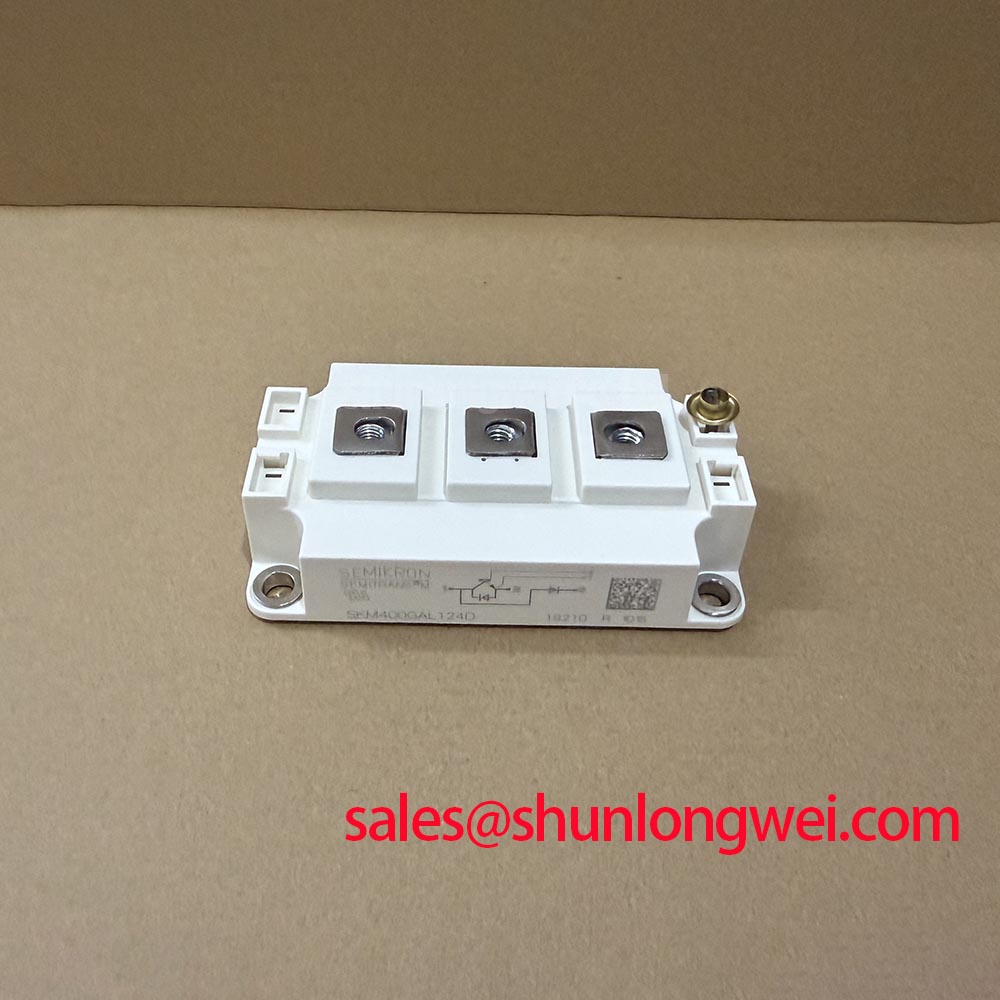

The SEMIKRON SKM400GAR12T4 is a fast single IGBT module engineered for robust performance in high-frequency power systems, offering a superior balance of switching speed and conduction efficiency. With its core specifications of 1200V | 400A | VCE(sat) of 2.2V (typ. at 150°C), this module delivers two critical engineering benefits: minimized switching losses and high short-circuit resilience. It directly addresses the need for durable power stages in applications like high-frequency DC/DC converters and electronic welders. For systems requiring robust switching up to 20 kHz while maintaining thermal stability, the SKM400GAR12T4 provides an optimized solution.

B3. Key Parameter Overview

Decoding the Specs for High-Frequency Operation

The technical specifications of the SKM400GAR12T4 are tailored for applications where switching efficiency and device protection are paramount. The following parameters highlight its suitability for demanding power conversion tasks.

| Parameter | Symbol | Condition | Value | Unit |

|---|---|---|---|---|

| Absolute Maximum Ratings (Tj = 25 °C unless otherwise specified) | ||||

| Collector-Emitter Voltage | VCES | - | 1200 | V |

| Continuous DC Collector Current | IC | Tc = 80°C, Tj = 175°C | 475 | A |

| Nominal Collector Current | ICnom | - | 400 | A |

| Short Circuit Withstand Time | tpsc | VGE ≤ 15V, Tj = 150°C | 10 | µs |

| Characteristics (Tj = 150 °C unless otherwise specified) | ||||

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 400A, VGE = 15V | 2.2 (typ.) / 2.4 (max.) | V |

| Gate-Emitter Threshold Voltage | VGE(th) | IC = 15.2mA | 5.8 (typ.) | V |

| Internal Gate Resistor | RGint | Tj = 25°C | 1.9 | Ω |

Download the SKM400GAR12T4 datasheet for detailed specifications and performance curves.

B2. Application Scenarios & Value

Achieving Robustness in High-Current DC Choppers and Welders

The SKM400GAR12T4 is specifically designed for high-power, high-frequency applications where reliability under harsh electrical conditions is non-negotiable. Its value is particularly evident in systems like industrial DC brake choppers and electronic welders. In a DC brake chopper used in a large Variable Frequency Drive (VFD), the IGBT must rapidly switch high currents to dissipate regenerative energy from a decelerating motor.

What is the primary benefit of its short-circuit capability? Enhanced system survivability during fault conditions. The module’s high short-circuit capability, self-limiting to 6 times the nominal current for 10µs, is a critical protective feature. This is like having an automotive airbag for the power circuit; it provides a crucial window for protection systems to react and prevent catastrophic failure of the inverter. This robustness allows designers to build more resilient systems that can withstand unexpected load conditions, reducing downtime and maintenance costs in industrial environments. For systems with even higher current demands, the SKM600GB12M7 can be considered for its increased current handling capacity.

B7. FAQ

How does the positive temperature coefficient of VCE(sat) benefit system design?

The positive temperature coefficient of the collector-emitter saturation voltage (VCE(sat)) is a key feature for ensuring stable parallel operation of multiple IGBT modules. As a device heats up under load, its VCE(sat) increases, which naturally helps balance the current distribution between parallel devices. This prevents one module from taking on a disproportionate share of the current, a condition known as thermal runaway, thereby enhancing the overall reliability and longevity of the high-power inverter system.

What is the significance of the integrated CAL (Controlled Axial Lifetime) diodes?

The integrated fast and soft inverse CAL diodes are crucial for reducing electromagnetic interference (EMI) and improving efficiency. During turn-off, these diodes exhibit "soft" recovery, meaning they avoid abrupt current changes that can cause voltage overshoots and ringing. This behavior simplifies the design of snubber circuits and filtering, leading to a more compact and cost-effective final product.

What design advantage is provided by the large clearance (10 mm) and creepage (20 mm) distances?

These specified distances are critical for high-voltage safety and compliance. Creepage is the shortest path between two conductive parts measured along the surface of the insulation, while clearance is the shortest distance through the air. The generous 10mm clearance and 20mm creepage distances ensure the module can safely handle high voltages without the risk of arcing, making it suitable for industrial systems operating on higher DC bus voltages and simplifying UL certification.

B1. Technical Deep Dive

Analyzing the SEMITRANS 3 Package and DBC Technology

The reliability and thermal performance of the SKM400GAR12T4 are fundamentally linked to its SEMITRANS 3 package and the use of Direct Copper Bonding (DBC) technology. The isolated copper baseplate, bonded directly to the ceramic substrate, provides excellent thermal conductivity and superior electrical isolation (4000V). This construction minimizes the thermal resistance from the IGBT chip to the heatsink, allowing for more efficient heat dissipation and a lower operating junction temperature. Think of DBC as a superhighway for heat; it provides a direct, low-resistance path for thermal energy to escape from the silicon chip to the cooling system. This efficient thermal management is essential for achieving the module’s high power cycling capability and ensuring long-term operational reliability, especially in applications with frequent start-stop cycles like servo drives.

B5. Industry Insights & Strategic Advantage

Meeting the Demands for Higher Power Density in Industrial Automation

The ongoing trend in industrial automation and power conversion is the drive for increased power density—delivering more processing power in a smaller physical footprint. The SKM400GAR12T4 directly supports this objective. Its ability to operate efficiently at higher switching frequencies (up to 20 kHz) allows for the use of smaller and lighter magnetic components, such as transformers and inductors, within the overall system. This reduction in passive component size is a key enabler for designing more compact power supplies and motor drives. By leveraging technologies like the fast trench IGBT and CAL diode, SEMIKRON provides engineers with a component that not only meets performance specifications but also aligns with the strategic need to reduce system size, weight, and ultimately, cost.

To discuss your specific application needs or to request further information, please contact our technical sales team for expert guidance.