Content last revised on October 31, 2025

7MBI100U4E-120-50: Fuji Electric 1200V 7-in-1 IGBT Module for Motion Control

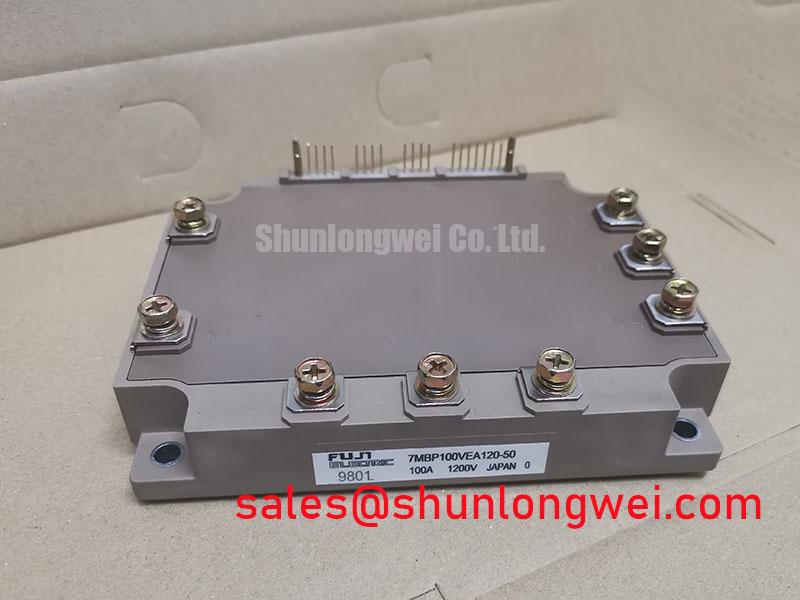

The Fuji Electric 7MBI100U4E-120-50 is a 1200V IGBT module engineered for high-performance, three-phase inverter applications. It integrates a three-phase bridge, a brake chopper, and a thermistor in a single compact package. With its balanced design focused on reducing both conduction and switching losses, this module provides a robust foundation for building efficient and reliable power conversion systems. Key specifications include: 1200V Vces | 100A Collector Current | Low VCE(sat). This integrated approach simplifies thermal management and streamlines assembly in complex motor drives and power supplies.

Key Parameter Overview

Decoding Specs for Integrated Three-Phase Inverter Designs

The electrical and thermal characteristics of the 7MBI100U4E-120-50 are optimized for industrial drive applications. The parameters below detail the module's capabilities, providing the necessary data for system design, simulation, and thermal evaluation.

| Parameter | Symbol | Condition | Value | Unit |

|---|---|---|---|---|

| Absolute Maximum Ratings (Tc = 25°C) | ||||

| Collector-Emitter Voltage | VCES | 1200 | V | |

| Gate-Emitter Voltage | VGES | ±20 | V | |

| Continuous Collector Current (Inverter) | IC | Tc = 80°C | 100 | A |

| Pulsed Collector Current (Inverter) | ICP | 1ms pulse | 200 | A |

| Continuous Collector Current (Brake) | IC | Tc = 80°C | 50 | A |

| Pulsed Collector Current (Brake) | ICP | 1ms pulse | 100 | A |

| Max Power Dissipation (Inverter) | PC | 540 | W | |

| Operating Junction Temperature | Tj | +150 | °C | |

| Electrical Characteristics (Tj = 25°C) | ||||

| Collector-Emitter Saturation Voltage (Inverter) | VCE(sat) | IC = 100A, VGE = 15V | 2.1 (Typ) / 2.7 (Max) | V |

| Collector-Emitter Saturation Voltage (Brake) | VCE(sat) | IC = 50A, VGE = 15V | 2.1 (Typ) / 2.7 (Max) | V |

| Gate-Emitter Leakage Current | IGES | VGE = ±20V | ±500 | nA |

| Collector-Emitter Cut-off Current | ICES | VCE = 1200V | 1.0 | mA |

| Forward Voltage Drop (FWD) | VF | IF = 100A | 2.0 (Typ) / 2.6 (Max) | V |

Application Scenarios & Value

Streamlining Servo Drive and Industrial Inverter Design

The 7MBI100U4E-120-50 is primarily engineered for power conversion systems where space, assembly efficiency, and reliability are critical. Its 7-in-1 topology, which includes the inverter stage and braking chopper, makes it a strong candidate for applications such as AC servo drives, general-purpose industrial inverters, and small-to-medium power Uninterruptible Power Supply (UPS) systems. The primary engineering value lies in its integration. For a design engineer developing a compact servo drive for factory automation, using this module eliminates the need for a separate braking IGBT and its associated wiring, gate drive circuit, and thermal considerations. This high level of integration directly reduces the bill of materials (BOM), simplifies the PCB layout, and shortens the assembly process. The built-in thermistor further enhances system reliability by providing a direct thermal feedback mechanism, crucial for implementing effective over-temperature protection in demanding robotic servo drives and preventing catastrophic failures.

Technical Deep Dive

Analyzing the Impact of the Integrated Braking Chopper

A key feature of the 7MBI100U4E-120-50 is the on-board braking chopper circuit. In motor drive applications, particularly during rapid deceleration, the motor acts as a generator, feeding energy back into the DC link. This regenerative energy causes the DC bus voltage to rise, which can damage capacitors and other components if left unmanaged. The integrated braking chopper provides an elegant solution. It acts like a controlled switch that diverts this excess energy into an external braking resistor, where it is safely dissipated as heat. The value of an integrated chopper extends beyond just component protection. It simplifies compliance with machinery safety standards like ISO 13849-1 by providing a reliable, pre-engineered method for energy dissipation. For engineers, this means less time spent on designing, validating, and sourcing a discrete braking solution, allowing for a faster time-to-market. The chopper's 50A continuous current rating is well-matched to the 100A inverter, providing robust braking capability for a wide range of industrial motor sizes.

Frequently Asked Questions (FAQ)

What is the primary benefit of the 7-in-1 configuration in the 7MBI100U4E-120-50?

The primary benefit is system simplification. By integrating the three-phase inverter, braking chopper, and NTC thermistor into one module, it significantly reduces component count, simplifies the printed circuit board layout, minimizes assembly labor, and centralizes thermal management, leading to a more compact and cost-effective final design.

How does the integrated NTC thermistor improve system reliability?

The integrated NTC thermistor provides real-time temperature feedback directly from the module's baseplate. This allows the motor drive's control system to accurately monitor the IGBT's operating temperature and trigger protective measures, such as reducing the switching frequency or shutting down the system, before a thermal runaway event can occur, thus preventing damage to the module and enhancing overall operational safety.

Engineering a More Integrated Power Stage

For engineering teams looking to accelerate their design cycle for motor control and power conversion systems, the 7MBI100U4E-120-50 offers a compelling platform. Its high level of integration provides a clear path to reducing system complexity and improving manufacturability. We encourage you to review the datasheet to see how its electrical and thermal characteristics align with your specific application requirements. For inquiries regarding evaluation or design support, please contact our technical team.