Content last revised on January 24, 2026

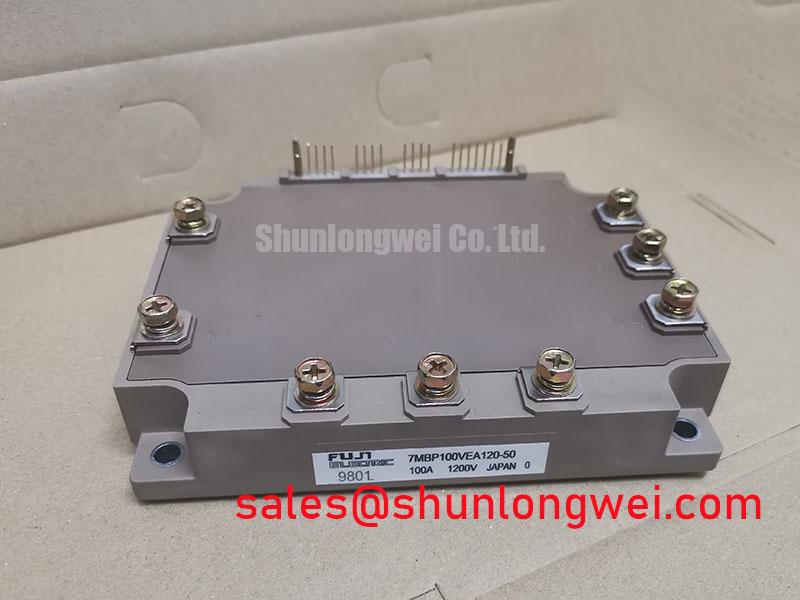

7MBP100VEA120-50: A 1200V/100A 7-Pack Intelligent Power Module for High-Efficiency Inverter Drives

The 7MBP100VEA120-50 from Fuji Electric is a highly integrated Intelligent Power Module (IPM) designed to streamline the development of compact and reliable motor drives. This module provides an optimized solution for power conversion by combining low-loss V-series IGBTs with dedicated gate drive and protection circuits. Key specifications include a 1200V collector-emitter voltage, a 100A continuous collector current, and a typical VCE(sat) of 1.7V. This integration results in two primary engineering benefits: significantly reduced conduction losses for improved thermal performance and simplified system design due to fewer external components. What is the topology of the 7MBP100VEA120-50? It is a 7-in-1 module with a three-phase inverter and a brake chopper. For motor drives up to 37 kW requiring integrated braking and precise thermal feedback, the 7MBP100VEA120-50 offers an optimal balance of performance and integration.

Key Parameter Overview

A Data-Centric Look at Performance and Operating Limits

The technical specifications of the 7MBP100VEA120-50 are tailored for demanding power conversion applications. The parameters below highlight its capability to deliver efficient and reliable performance. The module's characteristics support robust designs in variable frequency drives, servo systems, and other industrial inverters.

| Parameter | Symbol | Condition | Value | Unit |

|---|---|---|---|---|

| Absolute Maximum Ratings (Tc=25°C) | ||||

| Collector-Emitter Voltage | VCES | 1200 | V | |

| Collector Current (Continuous) | IC | 100 | A | |

| Collector Current (Peak) | ICP | 1ms | 200 | A |

| Collector Power Dissipation | PC | Per IGBT | 581 | W |

| Operating Junction Temperature | Tj | +150 | °C | |

| Electrical Characteristics (Tj=25°C) | ||||

| Collector-Emitter Saturation Voltage | VCE(sat) | IC=100A | 1.7 (Typ) / 2.2 (Max) | V |

| Turn-on Switching Loss | Eon | IC=100A, VCC=600V | 10.0 (Typ) | mJ |

| Turn-off Switching Loss | Eoff | IC=100A, VCC=600V | 7.5 (Typ) | mJ |

| Thermal Resistance (Junction to Case) | Rth(j-c) | IGBT Part | 0.215 (Max) | °C/W |

Download the 7MBP100VEA120-50 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in AC Motor Drive and Servo Applications

The 7MBP100VEA120-50 is engineered for core applications such as general-purpose inverters, Variable Frequency Drive (VFD) systems, and servo drives for factory automation. Its primary value lies in its high level of integration, which provides a tangible advantage in modern, power-dense designs.

Consider the engineering challenge of designing a compact VFD for a conveyor belt system. This application requires precise motor control and must safely manage regenerative energy during deceleration. The 7MBP100VEA120-50 directly addresses this by incorporating a brake chopper circuit within the same package as the three-phase inverter. This eliminates the need for a separate, bulky braking module, reducing both the bill of materials (BOM) and the overall system footprint. Furthermore, its low VCE(sat) of 1.7V at its nominal 100A rating translates directly to lower conduction losses. This reduction in waste heat simplifies Thermal Management, potentially allowing for a smaller heatsink and a more compact enclosure. For systems demanding higher current, the 6MBP150VEA120-50 provides a 150A capability in a similar integrated package.

Application Vignette

Vignette: Optimizing a Mid-Power VFD for Material Handling Systems

In automated warehousing, material handling systems undergo frequent start-stop cycles, placing significant thermal and electrical stress on the motor drive. A key challenge is ensuring long-term reliability without over-specifying the power stage. The 7MBP100VEA120-50's integrated features provide a robust solution.

The frequent braking events generate regenerative energy that must be dissipated. The module's integrated brake chopper, when connected to an external Brake Resistor, efficiently manages this energy, preventing DC bus overvoltage faults and protecting the system. More critically, the module includes built-in over-temperature protection. This is achieved by directly sensing the IGBTs' junction temperature, providing a much faster and more accurate response than an external NTC thermistor mounted on the heatsink. This allows the VFD controller to implement intelligent thermal rollback—reducing output power to prevent a critical shutdown—or to trigger a safe stop, vastly improving the operational lifespan and preventing catastrophic failure under demanding, repetitive load conditions.

Frequently Asked Questions

Engineering Inquiries on Implementation and Performance

How does the integrated over-temperature protection in the 7MBP100VEA120-50 improve system reliability?

The module provides an alarm signal (VALM) by directly detecting the IGBT junction temperature (Tj). This direct detection is far more accurate and responsive than relying on an external heatsink thermistor. It allows the system controller to take immediate protective action, such as reducing the switching frequency or shutting down the drive, before a destructive thermal runaway can occur, thereby enhancing the drive's operational lifetime.

What is the primary advantage of the low VCE(sat) rating in a Variable Frequency Drive (VFD) application?

A low VCE(sat), such as the 1.7V typical for this module, directly reduces power loss during the conduction phase of the IGBT. This loss manifests as heat (Power Loss = VCE(sat) * IC). By minimizing this value, the module operates more efficiently, generates less waste heat, and reduces the demand on the cooling system. This enables a higher power density, a smaller heatsink, and ultimately, a lower total cost of ownership.

For design engineers and procurement specialists, the 7MBP100VEA120-50 provides a well-documented, highly integrated foundation for developing next-generation motor control systems. The data and features detailed in the official documentation empower a streamlined and reliable design process from initial concept to final deployment.