Content last revised on January 15, 2026

Fuji 7MBI75SA-120B-50 | 1200V 75A PIM for High-Efficiency Motor Control

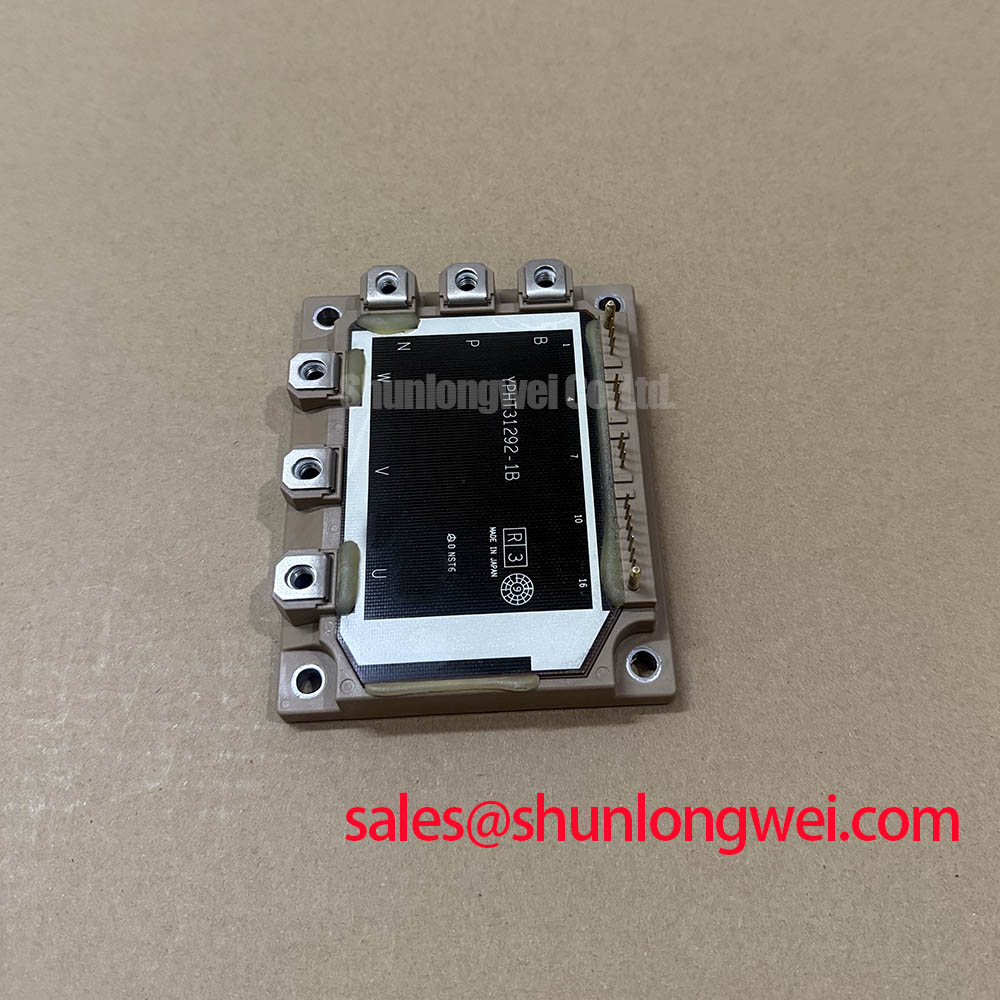

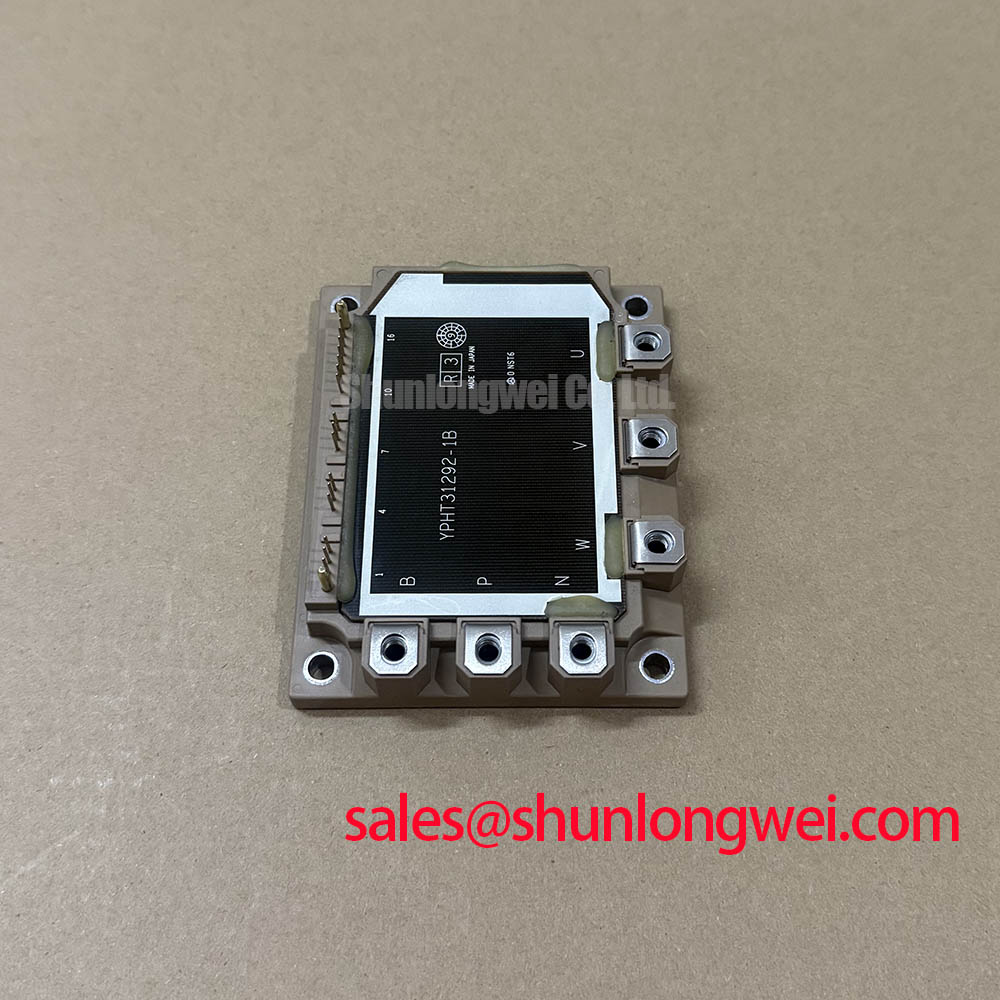

The Fuji 7MBI75SA-120B-50 is a 1200V, 75A Power Integrated Module (PIM) engineered specifically for engineers developing compact and highly reliable motor drive systems. By integrating a three-phase converter, a three-phase inverter, and a brake chopper into a single, thermally efficient package, this module streamlines system design, reduces assembly complexity, and enhances overall performance.

- High Integration (7-in-1): Combines a full three-phase diode bridge rectifier, a three-phase inverter stage, and a braking IGBT with a freewheeling diode. This significantly reduces the Bill of Materials (BOM) and required PCB space.

- Advanced 6th Generation V-Series IGBT Technology: Utilizes Fuji Electric's advanced trench-gate and field-stop technology, achieving an optimal balance between low conduction loss (VCE(sat)) and reduced switching losses.

- Enhanced Thermal Performance: Features a low thermal resistance package and an integrated NTC thermistor for precise, real-time temperature monitoring, enabling robust thermal protection strategies.

- Simplified Assembly: The M712 package offers a streamlined mechanical and electrical interface, reducing manufacturing time and improving production yields compared to discrete component solutions.

Application Scenarios & Value Proposition

The highly integrated nature of the Fuji 7MBI75SA-120B-50 makes it a cornerstone component for power conversion systems up to approximately 30kW. Its design directly addresses the core challenges in modern drive applications.

- Variable Frequency Drives (VFDs): For general-purpose AC motor control, the 7-in-1 topology provides a complete power stage solution. The low VCE(sat) minimizes heat dissipation, allowing for smaller heatsinks and more compact VFD enclosures—a critical factor in space-constrained industrial environments.

- Servo Drives: In precision motion control, the integrated brake chopper is invaluable. It provides a built-in mechanism for managing regenerative energy from the motor during rapid deceleration, improving system stability and protecting the DC bus without requiring external braking circuits.

- Industrial Automation Systems: For applications like conveyor belts, pumps, and fans, reliability is paramount. The module's reduced number of internal solder joints and connections, compared to a discrete solution, leads to a lower probability of failure, directly contributing to higher system uptime. Understanding the full scope of IGBT modules is key to appreciating this reliability gain.

Technical Deep Dive: V-Series Technology and PIM Advantages

The performance of the 7MBI75SA-120B-50 is rooted in two key design pillars: the silicon and the packaging. Fuji's 6th Generation V-Series IGBT technology employs a fine-patterned trench structure that significantly lowers on-state voltage drop. This directly translates to lower power losses during the conduction phase, a dominant loss factor in motor drive applications that operate at moderate switching frequencies. Furthermore, the optimized field-stop layer ensures fast, soft switching turn-off characteristics, which helps to mitigate voltage overshoots and reduces EMI generation, simplifying the design of snubber circuits and filtering.

The Power Integrated Module (PIM) architecture delivers system-level benefits that go beyond simple component consolidation. By placing all power semiconductors on a single insulated substrate, the parasitic inductance between the inverter bridge and the DC link is minimized. This is critical for reducing voltage spikes during high di/dt switching events, thereby improving the module's robustness and expanding the Safe Operating Area (SOA).

Key Parameter Overview

The following table highlights the critical specifications for design engineers.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1200V |

| Continuous Collector Current (IC) @ TC=80°C (Inverter Part) | 75A |

| Collector-Emitter Saturation Voltage (VCE(sat)) @ IC=75A | 1.80V (Typ.) / 2.30V (Max.) |

| Operating Junction Temperature (Tj) | +150°C (Max.) |

| Thermal Resistance, Junction to Case (Rth(j-c)) - Inverter IGBT | 0.27 °C/W (Max.) |

| Short Circuit Withstand Time (tsc) | ≥ 10µs |

Frequently Asked Questions (FAQ)

Our engineers often receive questions about implementing modules like the 7MBI75SA-120B-50. Here are some expert answers to common queries.

- How does the integrated NTC thermistor improve my design?

The built-in NTC provides a direct, accurate measurement of the module's baseplate temperature. This allows the system controller to implement precise over-temperature protection (OTP) and dynamic thermal rollback. Instead of relying on external sensors with potential thermal lag, you get a real-time feedback loop that protects the IGBT modules from catastrophic failure and allows you to push the performance envelope safely. Effective thermal management is crucial for reliability. - Is a PIM like this truly more cost-effective than discrete components?

While the upfront cost of a PIM may be higher than the sum of individual discrete IGBTs and diodes, the total cost of ownership (TCO) is often significantly lower. A PIM reduces PCB complexity, assembly time, and labor costs. It also simplifies inventory management and procurement. Most importantly, the pre-engineered thermal and electrical layout within the module can lead to smaller heatsinks and fewer passive components, a point we explore in our guide on module vs. discrete designs.

For detailed selection advice or to discuss how the Fuji 7MBI75SA-120B-50 can fit into your next power conversion project, please contact our technical team.