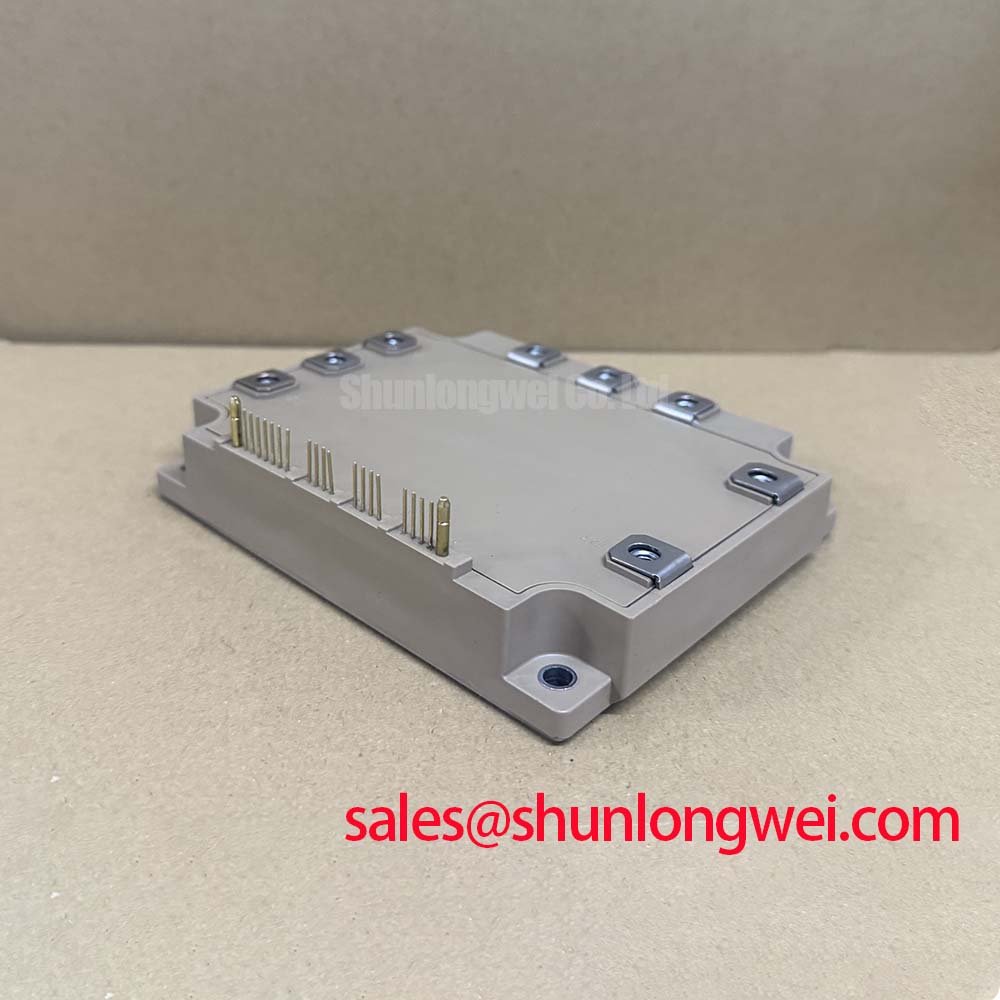

6MBP300VEA060-58: Fuji V-Series 600V 300A IPM Module

This Fuji Electric V-Series Intelligent Power Module (IPM) accelerates system design by integrating the gate drive, protection circuits, and a 6-pack IGBT array. Core Specs: 600V | 300A | V-Series Technology. Key Benefits: Reduced component count and simplified thermal design. It directly addresses the challenge of implementing robust fault protection by embedding over-current and over-temperature sensors that provide a direct alarm signal, streamlining control logic and enhancing system reliability.

Deploying Integrated Power in Demanding Motor Control

The 6MBP300VEA060-58 is engineered for power conversion systems where reliability and a compact footprint are critical design criteria. Its highly integrated nature makes it a strong candidate for a range of motor control applications, reducing both the physical size of the power stage and the engineering time required for development. The module's architecture is particularly valuable in environments that demand consistent performance and robust self-protection capabilities.

- Variable Frequency Drives (VFDs): The module's ability to manage 300A facilitates precise and efficient control of large induction motors used in industrial machinery, pumps, fans, and conveyor systems.

- Commercial HVAC Systems: In high-capacity air conditioning and refrigeration units, the integrated protection features ensure operational safety and longevity, minimizing downtime.

- Servo Drives and Robotics: For applications requiring high-precision motion control, the optimized gate drive and low-loss V-Series IGBTs enable accurate and responsive power delivery to servo motors. For systems with different power requirements, the 7MBR50VP120-50 provides a 1200V, 50A alternative.

For motor drives up to ~150 kW requiring rapid development cycles, this 300A IPM offers an optimal balance of integration and power handling.

Meeting Industry 4.0 Demands with Intelligent Module Design

The evolution towards smarter, more connected industrial environments places new demands on power electronics. The core value of an Intelligent Power Module like the 6MBP300VEA060-58 lies in its ability to abstract away complexity. What is the main benefit of an IPM like the 6MBP300VEA060-58? It simplifies design by integrating the gate drive and protection circuits. Instead of designing, validating, and sourcing separate gate drivers, protection logic, and discrete IGBTs, engineers can leverage a pre-validated subsystem. This approach directly supports faster time-to-market and allows development teams to focus on higher-level system control and application-specific software, which are key differentiators in the Industry 4.0 landscape. This module embodies the principle of functional integration, a crucial enabler for creating more compact and reliable automated systems. For a deeper understanding of how these modules fit into modern power systems, explore this guide on IPM vs. Discrete IGBTs.

Data-Backed Considerations for Your Drive System

Evaluating power modules requires a data-centric approach. As a distributor, our goal is to provide clear, factual information to support your component selection process. The following points highlight key datasheet parameters for an objective engineering assessment. This information is intended to empower your design decisions, not to guide them.

- Current and Voltage Ratings: The 6MBP300VEA060-58 is specified for a collector current (Ic) of 300A and a collector-emitter voltage (Vces) of 600V, defining its primary operating envelope for 200V-class AC motor drives.

- Integrated Functionality: This module is an IPM (Intelligent Power Module), which inherently includes optimized gate drive circuits and protection features. This contrasts with discrete IGBTs or Power Integrated Modules (PIMs) that require external drive and protection logic, impacting board space and design complexity.

- Protection Features: The module includes built-in protection against Over-Current (OC), Short-Circuit (SC), Control Power Supply Under-Voltage (UV), and Over-Temperature (OT). The alarm signal (VFO) output provides a direct feedback mechanism to the system controller.

Critical Specifications for Simplified System Design

The performance of the 6MBP300VEA060-58 is defined by a set of parameters optimized for integrated motor drive applications. The table below highlights key specifications from the datasheet and their direct engineering implications, following a value-centric format.

| Parameter | Value | Engineering Significance |

|---|---|---|

| Collector-Emitter Voltage (Vces) | 600V | Provides a secure voltage margin for operation in 200-240V AC line applications, ensuring robustness against voltage transients. |

| Collector Current (Ic) @ Tc=80°C | 300A | Defines the continuous current handling capability under typical industrial operating temperatures, directly correlating to the module's output power capacity. |

| Over Temperature (OT) Protection | Trip Level: 125°C (Tj) | Offers autonomous thermal protection by triggering an alarm when the IGBT junction temperature exceeds a safe limit, preventing catastrophic failure. This is like a built-in thermostat for the power stage. |

| Isolation Voltage (Viso) | 2500 Vrms (1 min) | Ensures high dielectric strength between the power terminals and the mounting baseplate, a critical safety requirement for UL compliance and operator protection. |

| Control Supply Voltage (Vcc) | 15V ± 10% | Operates from a standard 15V rail, simplifying the system's power supply architecture and reducing the need for multiple voltage regulators. |

Download the Datasheet for complete specifications.

Architectural Breakdown: The Core of Integrated Protection

The fundamental advantage of the 6MBP300VEA060-58 is its cohesive internal architecture. What protection features are included? This module includes built-in over-current and over-temperature protection. This integration moves critical, high-speed protection functions from the main control board directly to the power semiconductor. The internal logic continuously monitors the current through the IGBT emitters and the temperature via a sensing diode. If a fault threshold is breached, the control IC immediately initiates a soft shutdown of the respective IGBT and asserts the common fault alarm pin (VFO). This localized, rapid response is significantly faster than what can typically be achieved with external current shunts and microcontroller-based monitoring, providing a superior level of protection against destructive events. This design philosophy simplifies the overall system and enhances its resilience, a topic further explored in articles on preventing IGBT failures.

Technical Inquiries for the 6MBP300VEA060-58

1. How does the integrated over-current protection (OC) in the 6MBP300VEA060-58 function?

The module uses a sense-emitter connection on the lower-side IGBTs to monitor current. If the current exceeds a pre-set internal threshold (typically around 2.0 times the rated Ic), the internal control IC triggers a fault condition, initiating a soft shutdown of the IGBTs and sending an alarm signal to the VFO pin.

2. What is the purpose of the alarm signal (VFO) pin?

The VFO (Fault Output) is an open-collector output that signals a fault condition (OC, SC, UV, or OT) to the host microcontroller. This allows the system controller to take appropriate action, such as shutting down the system, displaying an error code, or logging the fault, without needing complex external sensing circuits.

3. Can I parallel these IPM modules for higher current output?

Paralleling IPMs is generally not recommended without careful consideration and is often not supported by manufacturers. The integrated gate drives and protection circuits are optimized for a specific IGBT array, and imbalances in current sharing can lead to unintended tripping of protection circuits or thermal runaway. For higher current needs, it is typically better to select a single module with a higher current rating, such as the CM600DX-24T which handles 600A.

4. What are the key thermal management considerations for this 300A module?

Effective thermal management is crucial. A properly sized heatsink with low thermal resistance is required to keep the case temperature (Tc) within the specified limits. The use of a high-quality thermal interface material (TIM) with a recommended thickness is essential to minimize the thermal resistance between the module's baseplate and the heatsink, ensuring efficient heat transfer away from the IGBT junctions.

5. Does the control circuit require a separate isolated power supply?

Yes, the internal high-side gate drivers are powered via a bootstrap circuit, but the module's primary control logic requires a single, isolated 15V DC power supply (Vcc) that is referenced to the main emitter terminals. It is critical that this supply is stable and meets the under-voltage (UV) protection thresholds to ensure proper operation.

An Engineer's Perspective on Future Designs

From a design standpoint, modules like the 6MBP300VEA060-58 represent a crucial step in the modularization of power electronics. While offering significant benefits in integration, the next design frontier involves optimizing the interplay between the IPM and the system's control algorithm. Future development could focus on leveraging the module's fault feedback to enable more sophisticated diagnostic and prognostic routines. Instead of a simple shutdown, a controller could use fault data to adapt its PWM strategy, derate power gracefully, or predict maintenance needs, leading to systems that are not just protected, but truly intelligent and self-aware. The foundation laid by such integrated modules is what makes these future advancements possible.