Content last revised on November 13, 2025

## Infineon / EUPEC BSM100GB170DLC | A High-Voltage Workhorse for Robust Power Conversion

The Infineon BSM100GB170DLC is an industry-proven dual IGBT module engineered for high-reliability power conversion systems. As a legacy component originally from EUPEC, this module has established a track record for exceptional ruggedness and stable performance in demanding applications where high voltage capability is non-negotiable. It embodies a design philosophy focused on durability and a wide safety margin, making it a trusted choice for engineers designing or maintaining critical power infrastructure.

Key attributes of the BSM100GB170DLC include:

- 1700V Collector-Emitter Voltage (V_CES): Provides a substantial safety margin for systems operating on high DC-link voltages, effectively mitigating risks from voltage spikes and transients.

- 100A Nominal Collector Current: Delivers ample current handling for a wide range of medium-power industrial applications.

- Half-Bridge Configuration: Features two IGBTs in a series configuration with integrated freewheeling diodes, ideal for building inverter legs, choppers, and other classic power topologies.

- Proven NPT Technology: Built on Non-Punch-Through (NPT) IGBT technology, prized for its robustness, wide Safe Operating Area (SOA), and superior short-circuit withstand capabilities.

### Key Technical Specifications

The following parameters represent the core operational characteristics that define the performance of the BSM100GB170DLC. These values are essential for system-level simulation, thermal design, and performance validation.

| Parameter | Value |

|---|---|

| Max. Collector-Emitter Voltage (V_CES) | 1700V |

| Nominal DC Collector Current (I_C_nom) | 100A |

| Collector-Emitter Saturation Voltage (V_CE(sat)) at I_C_nom | 3.9V (Typ.) at Tj=125°C |

| Topology / Configuration | Half-Bridge (Dual IGBT) |

| Max. Junction Temperature (T_jmax) | 150°C |

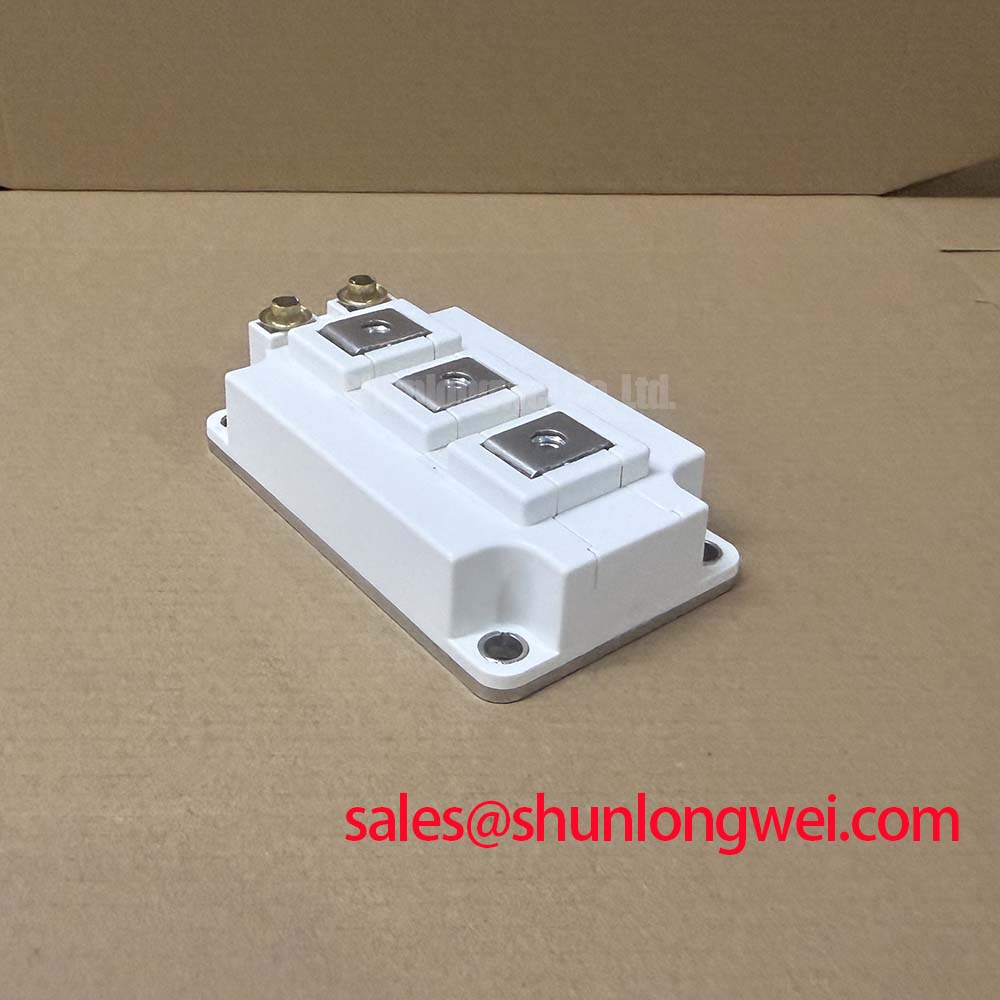

| Package | Standard Industrial Module |

For a comprehensive list of electrical and thermal characteristics, designers should reference the official BSM100GB170DLC datasheet.

### Engineering Deep Dive: The Value of Robustness over Raw Efficiency

In modern power electronics, the focus is often on minimizing conduction losses (V_CEsat). While the BSM100GB170DLC features a higher V_CEsat compared to the latest generation IGBTs, this is a deliberate engineering trade-off. Its NPT chip technology delivers exceptional ruggedness. This translates into a higher tolerance for fault conditions like short circuits and overvoltages, which is a critical requirement in applications where downtime is unacceptable. The positive temperature coefficient of its V_CEsat also promotes even current sharing when paralleling modules, simplifying the design of higher-power systems. For more on preventing component failure, explore our guide to IGBT failure analysis.

### Primary Application Arenas

The unique combination of high voltage rating and proven reliability makes the BSM100GB170DLC an ideal solution for specific, demanding power conversion tasks.

- Industrial Motor Drives: Perfectly suited for variable frequency drives (VFDs) and servo drives connected to 690V AC industrial grids, where the 1700V rating provides essential protection against DC-link voltage fluctuations.

- Renewable Energy Systems: A solid choice for central solar inverters and wind turbine converters, particularly in legacy systems or designs prioritizing long-term field reliability over achieving the absolute highest efficiency figures.

- Uninterruptible Power Supplies (UPS): Its robust nature ensures continuous, reliable operation in large-scale UPS systems that protect critical data centers, hospitals, and industrial processes.

- Welding and Induction Heating: In applications like high-frequency induction heating, the module's ability to withstand harsh electrical conditions is paramount for consistent performance.

### Frequently Asked Questions (FAQ)

Q1: Can the BSM100GB170DLC be used as a replacement for a 1200V module?

A: While electrically compatible in terms of footprint and function, substituting a 1700V module for a 1200V one is an over-specification unless the system requires a higher safety margin. The higher V_CEsat of the 1700V device will result in increased conduction losses compared to a modern 1200V equivalent. This change should only be made after careful analysis of the system's thermal management capabilities.

Q2: What are the critical gate drive considerations for this module?

A: Due to its high voltage rating, a robust and well-designed gate drive circuit is crucial. To ensure reliable and fast turn-off and to prevent parasitic turn-on induced by the Miller effect, a negative gate voltage (e.g., -8V to -15V) is strongly recommended. Additionally, clean power rails and minimized loop inductance in the gate drive path are essential for optimal switching performance.