EL320.256-FD6 TFEL Display for Extreme Environment Reliability

Engineered for Unfailing Clarity Where Other Displays Fail

The Lumineq EL320.256-FD6 is a Thin Film Electroluminescent (TFEL) display engineered for unwavering visual clarity and operational integrity in environments subject to extreme temperatures, severe shock, and high vibration. Where conventional liquid-crystal displays face risks of freezing, slow response, or physical damage, this solid-state panel delivers consistent performance. Its design directly addresses the core engineering challenge of HMI reliability in harsh conditions by eliminating the physical failure points inherent in other display technologies, ensuring critical data remains accessible.

Top Specs: 320x256 Resolution | -40°C to +85°C Operating Temperature | 100 G Shock Tolerance

Key Benefits:

- Exceptional environmental immunity

- Long-term operational stability

Deconstructing the EL320.256-FD6 for Unmatched Durability

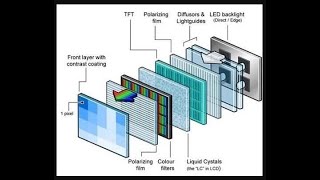

The foundational strength of the Lumineq EL320.256-FD6 stems from its solid-state TFEL construction. This technology deposits inorganic light-emitting materials between transparent dielectric layers and a substrate, creating a robust, monolithic glass structure. Unlike TFT-LCD panels that rely on a liquid crystal layer susceptible to temperature changes and mechanical stress, this display’s pixels are inherently durable. What is the primary benefit of its solid-state design? It provides intrinsic resistance to mechanical shock and vibration without requiring external dampeners or ruggedized enclosures.

This structural integrity is complemented by an exceptionally wide operating temperature range. The display maintains consistent brightness, contrast, and a sub-millisecond response time from -40°C to +85°C. This performance is a direct result of the physics of electroluminescence, which is not dependent on the fluid-dynamics that govern liquid crystals. For engineers, this eliminates the need for costly and power-intensive heating or cooling subsystems often required to keep other displays within their functional thermal window.

A Factual Comparison: TFEL vs. Industrial TFT in Demanding Roles

When selecting a display for demanding environments, engineers must evaluate technologies based on their physical limitations. The table below presents a data-focused comparison to aid in this assessment. The objective is not to declare a superior technology, but to provide the factual basis for an informed system design decision, particularly when reliability is the primary consideration.

| Parameter | EL320.256-FD6 (TFEL) | Typical Industrial TFT LCD |

|---|---|---|

| Operating Temperature | -40°C to +85°C | -20°C to +70°C (standard); wider ranges require heaters |

| Shock Tolerance | 100 G, 6 ms pulse | 15-30 G (varies, often requires mechanical isolation) |

| Response Time | < 1 ms (across all temperatures) | 15-35 ms (can increase significantly at low temperatures) |

| Viewing Angle | >160° (uniform) | Varies by technology (e.g., IPS, TN); can be viewing-cone dependent |

| Failure Mode in Cold | None; instant-on performance | Sluggish response, freezing of liquid crystals, backlight issues |

This data highlights a key trade-off: while industrial TFTs offer color and higher resolutions, the EL320.256-FD6 provides a level of environmental resilience that is structurally unattainable for liquid-crystal based technologies.

Field-Proven Performance in Critical Systems

The inherent ruggedness of the EL320.256-FD6 is not just a datasheet specification; it is validated through its deployment in some of the world's most demanding applications. This display technology is frequently integrated into military ground vehicles, avionics dashboards, and marine navigation systems where failure is not an option. In the industrial sector, it serves as the human-machine interface on heavy-duty machinery in mining, agriculture, and oil and gas exploration, providing clear readability amidst constant vibration and temperature swings. This track record provides system architects with a high degree of confidence in the display's long-term reliability and low total cost of ownership.

Where Resilience is the Primary Design Criterion

The EL320.256-FD6 is engineered for applications where data visibility under punishing conditions is paramount. Its unique characteristics make it a critical component in systems deployed beyond the confines of controlled environments. Key application areas include:

- Avionics and Aerospace: Certified for high-altitude operation (up to 18,000 ft), its immunity to pressure changes and extreme temperatures ensures reliable cockpit and cabin instrumentation.

- Heavy Machinery and Off-Highway Vehicles: With a 100 G shock tolerance, the display provides a stable HMI for excavators, harvesters, and mining trucks where severe, repetitive impacts are standard. For more insights on this topic, review our guide on engineering reliable displays for heavy machinery.

- Rail and Mass Transit: Delivers consistent performance in driver control panels and signaling systems exposed to wide temperature shifts and constant track vibration.

- Industrial Process Control: Ideal for control panels in foundries, cold storage facilities, and outdoor installations where standard displays would quickly degrade or fail.

For avionics or heavy machinery HMIs where operational temperature is below -20°C and shock exceeds 50 G, the EL320.256-FD6 is the definitive choice for long-term reliability.

Engineering Specifications for Harsh-Environment Integration

The following parameters are central to the EL320.256-FD6's value proposition. They provide the quantitative data needed for robust system design and integration.

| Key Metric | Value |

|---|---|

| Display Technology | Thin Film Electroluminescent (TFEL) |

| Resolution | 320 x 256 pixels |

| Operating Temperature Range | -40°C to +85°C |

| Shock Resistance | 100 g-force, 6 ms half-sine |

| Vibration Resistance | 5 to 500 Hz, 0.05 g²/Hz random vibration |

| Typical Luminance | 45 cd/m² at 120 Hz |

Download the Operation Manual for complete electrical and mechanical specifications.

The shock tolerance of 100 G is a critical differentiator. To put this in perspective, this is a force comparable to what pilots experience during an aircraft ejection seat activation. It means the display is not merely 'ruggedized' but structurally engineered to survive catastrophic mechanical events, a factor that can significantly lower the total cost of ownership in high-risk applications.

Future-Proofing HMIs in an Era of Edge Deployment

The industry trend towards decentralized intelligence and IoT places advanced processing and data visualization at the network edge. This often means deploying complex electronics directly into harsh operational environments, from remote pipelines to autonomous agricultural vehicles. In this context, the reliability of the human-machine interface becomes a critical enabler of the entire system's value. The EL320.256-FD6 represents more than a component; it is a strategic choice that de-risks the deployment of technology in these expanding, challenging frontiers. By specifying a display with a proven tolerance for physical and thermal extremes, engineers are not just designing for today's requirements but are building a foundation of reliability that will support the entire lifecycle of the asset. For systems requiring alternative resolutions, the related AA084VC03 offers a different feature set for consideration.