G150XG01 V3: Industrial LCD with Wide Temp & Anti-Glare

Engineered for environmental resilience and long-term operational integrity, the AUO G150XG01 V3 is a 15.0-inch XGA display built to perform where standard panels falter. As industrial automation and outdoor systems demand components that can withstand wider environmental variants, the need for displays that offer consistent readability and durability has become paramount. This panel directly addresses that trend. Its design prioritizes sustained performance in fluctuating temperatures and challenging light, ensuring that critical data remains clear and accessible. For engineers developing systems for harsh conditions, this focus on fundamental robustness simplifies thermal management and enhances end-product reliability.

The Strategic Value of Environmentally Resilient Displays

In today's interconnected industrial landscape, the reliability of a Human-Machine Interface (HMI) is not a luxury; it is a core component of system uptime and operational safety. The selection of a display module increasingly hinges on its ability to withstand environmental stressors. The AUO G150XG01 V3 is built on this principle, offering a strategic advantage to system designers. Its wide operating temperature range reduces the need for auxiliary heating or cooling components, directly lowering the bill of materials (BOM) and simplifying the mechanical enclosure design. This approach not only saves initial costs but also reduces potential points of failure, contributing to a lower total cost of ownership over the product's lifespan. This is a crucial consideration when comparing against panels that may have a lower initial price but require more extensive environmental support systems. For a deeper understanding of these long-term value calculations, explore our guide on Industrial vs. Consumer Displays.

Data-Driven Comparison for System Integration

To empower your design and procurement decisions, this section provides factual data points for evaluation. The G150XG01 V3 is positioned to offer a specific balance of features geared towards environmental toughness. When evaluating alternatives, it is crucial to consider how parameters like temperature range and surface treatment align with your application's specific operational environment. Systems requiring higher resolution or a different interface may find panels like the G150XNE-L01 to be a relevant data point for comparison, as it offers a similar screen size with different specifications.

The table below outlines key metrics for an objective assessment. Please note that all data is provided for technical evaluation purposes and does not imply availability or direct interchangeability.

| Feature | AUO G150XG01 V3 | Typical Standard Industrial Panel |

|---|---|---|

| Operating Temperature | -30°C to +80°C | 0°C to +50°C |

| Surface Treatment | Anti-Glare | Glare or Anti-Glare |

| Backlight Lifetime (Typ.) | 50,000 Hours | 20,000 - 30,000 Hours |

| Interface | LVDS (1 ch, 6/8-bit) | LVDS / eDP |

Application Arenas for the G150XG01 V3

The specific feature set of the G150XG01 V3 makes it exceptionally well-suited for applications where environmental conditions are a primary design constraint. Its ability to function reliably in sub-zero and high-heat environments opens up deployments that are inaccessible to standard commercial-grade displays.

- Outdoor Kiosks and Ticketing Systems: The anti-glare surface ensures screen legibility in bright ambient light, while the wide temperature range allows for year-round operation in varying climates without failure.

- Industrial Control Panels: In factories, foundries, or processing plants, this display can be integrated into HMIs that are exposed to significant temperature swings near machinery or external doors.

- Transportation and Marine Systems: The panel's durability is advantageous for vehicle-mounted displays in logistics, construction equipment, or on-deck marine instrumentation where temperature and light conditions are uncontrolled.

- Cold Chain and Refrigerated Logistics: What defines its reliability in extreme cold? A validated operational floor of -30°C makes it suitable for control interfaces in cold storage warehouses and refrigerated transport.

For outdoor kiosks or unheated warehouses requiring consistent uptime, its -30°C operational limit makes the G150XG01 V3 a more robust choice than standard 0°C panels.

G150XG01 V3: A Breakdown of Key Technical Parameters

Effective system integration starts with a clear understanding of the component's core specifications. The G150XG01 V3 provides a balanced set of parameters optimized for industrial clarity and longevity. The following table highlights specifications from the official datasheet and explains their engineering significance, providing a foundation for your design evaluation.

Download the complete G150XG01 V3 Datasheet

| Parameter | Value | Engineering Significance |

|---|---|---|

| Screen Size | 15.0 inch | Provides a substantial active area for complex GUIs in industrial control and information displays. |

| Resolution | 1024(RGB)×768, XGA | Offers a standard resolution that is widely supported by industrial controllers and single-board computers, ensuring broad compatibility. |

| Operating Temperature | -30 ~ 80 °C | Critical for Reliability: This wide range allows deployment in unconditioned environments, from cold storage to sun-exposed enclosures, without requiring costly thermal management systems. |

| Brightness | 300 cd/m² (Typ.) | Delivers solid visibility for typical indoor industrial environments and shaded outdoor use. |

| Viewing Angle | 80/80/70/70 (Typ.)(CR≥10) | Ensures that information is clearly readable from off-axis positions, a key safety and usability factor for operators who may not be directly in front of the screen. |

| Backlight Lifetime | 50,000 hours (Min.) | Lifecycle Value: This translates to over 5.7 years of 24/7 continuous operation, minimizing maintenance cycles and ensuring long-term operational consistency. |

Technical Foundations of its Environmental Endurance

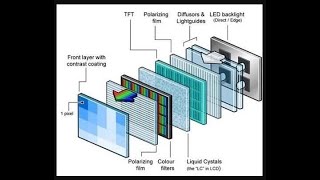

The robust performance of the G150XG01 V3 is not accidental; it stems from specific design and material choices. The use of an a-Si TFT (Amorphous Silicon) glass substrate provides a stable and proven foundation for industrial applications. The LED backlight system is a key contributor to its longevity and wide temperature performance. Unlike older CCFL technology, LEDs are solid-state devices that are inherently more resistant to shock and vibration and do not suffer from the startup issues in cold temperatures. What is the primary benefit of its anti-glare surface? It uses microscopic etching to diffuse ambient light, preventing mirror-like reflections that can render a screen unreadable. This diffusion is crucial for maintaining operator focus and data accuracy in brightly lit control rooms or outdoor settings.

Deployment Spotlight: Ensuring Uptime in the Field

While specific customer deployments are confidential, the G150XG01 V3 is frequently integrated into systems that share common challenges: the need for unwavering performance despite environmental volatility. For instance, in agricultural technology, this display serves as the main HMI in tractor cabs, which experience everything from sub-zero morning starts to intense solar heating in the afternoon. Similarly, in public-facing information terminals located in transportation hubs, the panel's resilience ensures that vital travel information remains accessible to the public around the clock, regardless of the season. These examples highlight how the display's core features directly translate into real-world operational continuity, a cornerstone of designing for extreme environments. For more insights, refer to our guide on engineering reliable displays for heavy machinery.

Frequently Asked Questions (FAQ)

1. What is the significance of the -30°C minimum operating temperature?

This specification validates the display for use in freezing environments, such as unheated warehouses, outdoor terminals in cold climates, and cold-chain logistics equipment, without requiring a dedicated internal heater. This simplifies system design and improves overall reliability by reducing component count.

2. How does the anti-glare (AG) surface treatment impact image quality?

The AG coating diffuses harsh external light, significantly improving readability under direct overhead lighting or near windows. While it can slightly soften the image sharpness compared to a glossy screen, this trade-off is critical in industrial settings to reduce operator eye strain and prevent errors caused by screen reflections.

3. What does a 50,000-hour backlight lifetime mean in practical terms?

A 50,000-hour minimum lifetime means the backlight's brightness is engineered to remain at 50% or more of its initial value after approximately 5.7 years of continuous 24/7 operation. This is a key indicator of long-term reliability and low maintenance requirements.

4. Is the LVDS interface on the G150XG01 V3 compatible with modern embedded systems?

Yes, the LVDS interface remains a widely used standard in industrial computing. It is known for its noise immunity and is supported by a vast number of single-board computers (SBCs) and industrial motherboards, ensuring straightforward integration. The panel supports both 6-bit and 8-bit color depth over a single channel.

5. Can the G150XG01 V3 be mounted in both portrait and landscape orientations?

The mechanical specifications support mounting in either orientation. However, designers should consider the viewing angle characteristics. The datasheet specifies optimal viewing horizontally. If portrait mode is a primary use case, it is important to evaluate the 70-degree vertical viewing angles to ensure they meet the application's ergonomic and readability requirements.

Designer's Perspective: Future-Proofing with Robust Components

As you architect the next generation of industrial or outdoor systems, the choice of a display module extends beyond its immediate specifications. Selecting a component like the G150XG01 V3 is a forward-looking decision. By building in environmental resilience at the component level, you create a more robust and adaptable final product. This reduces future service costs, broadens the potential market for your equipment to more demanding climates, and builds a reputation for reliability. The engineering challenge is shifting from simply displaying data to ensuring that data is dependably accessible, anywhere and anytime. Integrating a panel designed with this philosophy is a direct investment in that future.