Content last revised on November 21, 2025

Engineered for Consistency in Demanding AC Drive Applications

Delivering Stable Performance and Thermal Resilience for Compact Inverter Designs

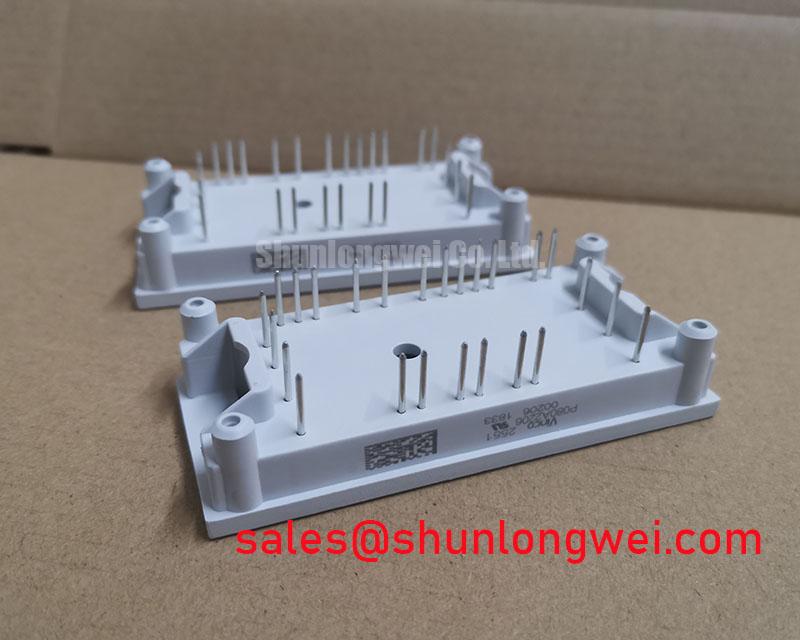

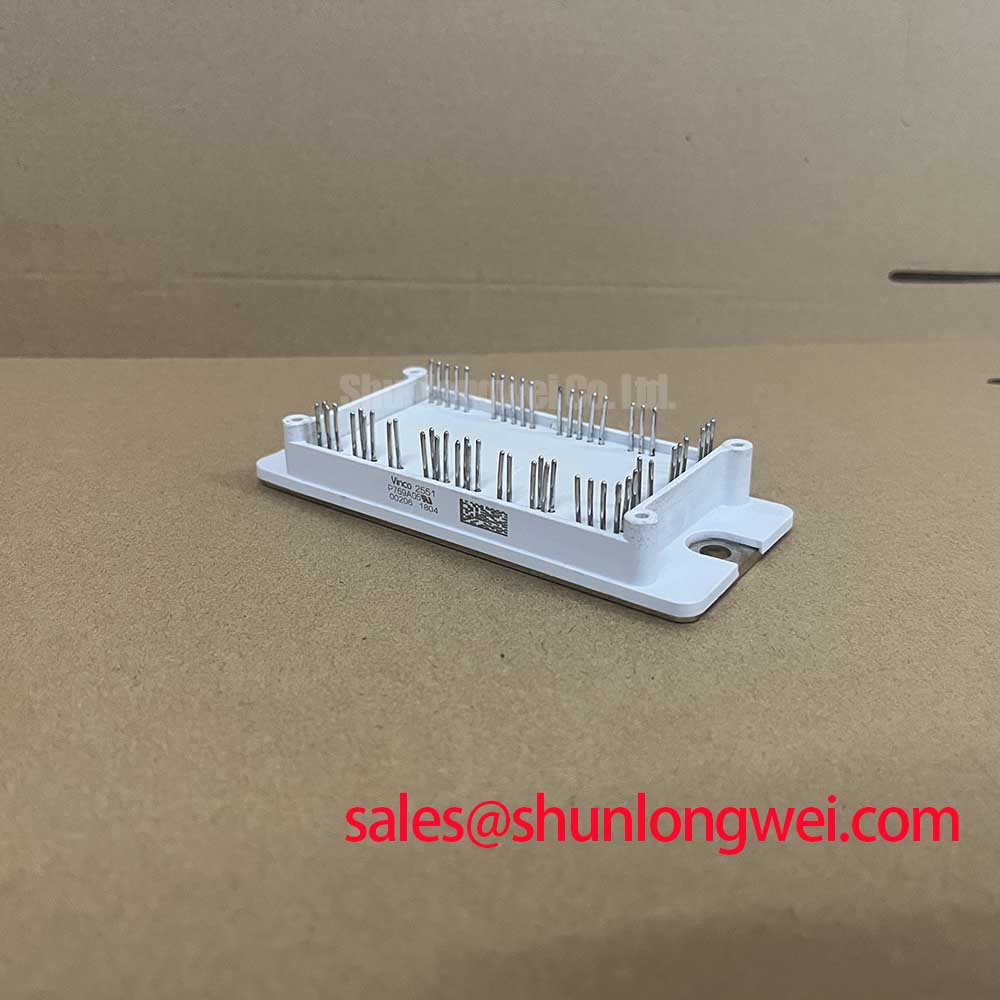

The Vinco K209A05 is an Insulated Gate Bipolar Transistor (IGBT) module designed to provide a stable and reliable power switching solution for low-power industrial systems. It offers a robust electrical specification of 600V and 15A, ensuring dependable operation in its target applications. Key benefits include consistent thermal performance and high electrical resilience, which are critical for the longevity of motor drives and power converters. This module directly addresses the engineering need for a component that can maintain performance integrity under the electrical and thermal stresses typical of compact industrial environments, making it a strong candidate for systems where long-term reliability is a primary design criterion. For applications requiring higher voltage blocking capabilities, such as those operating on higher industrial line voltages, the related SKM75GB128D provides a 1200V alternative.

Application Scenarios & Value

Optimizing Performance in Auxiliary Motor Control and Small AC Inverter Drives

The K209A05 is best suited for power conversion systems where efficiency and reliability are paramount, particularly in the sub-2kW range. Its specifications make it a practical choice for small AC inverter drives, which are fundamental components in automated manufacturing for controlling conveyor belts, fans, and pumps.

A primary engineering challenge in these compact drive designs is managing thermal load without complex cooling systems. The K209A05's architecture is focused on efficient switching, which helps to minimize energy loss as heat. This directly translates to a reduced thermal burden on the system, allowing engineers to design more compact enclosures and potentially reduce or eliminate the need for forced-air cooling, thereby simplifying the overall mechanical design and lowering the bill of materials. Its robust build ensures it can handle the repetitive electrical cycles inherent in motor control applications, contributing to greater system uptime. For engineers designing for variable frequency drives or small uninterruptible power supplies, this module provides a dependable core switching component.

Key Parameter Overview

Core Specifications Highlighting Electrical Robustness

The technical parameters of the K209A05 underscore its suitability for low-power industrial switching applications. The highlighted specifications below are critical for ensuring the device operates reliably within its intended design envelope.

| Parameter | Value | Engineering Significance |

|---|---|---|

| Collector-Emitter Voltage (Vces) | 600V | Provides a sufficient voltage margin for systems operating on 230V or 400V AC lines, protecting against common line voltage transients. |

| Continuous Collector Current (Ic) | 15A | Defines the maximum continuous current handling capability, suitable for driving fractional horsepower motors and other low-power loads. |

| Configuration | Power Module | Integrates multiple components into a single package, simplifying assembly and PCB layout compared to discrete solutions. |

Download the datasheet for K209A05 for detailed specifications and performance curves.

Technical Deep Dive

Understanding the Impact of Integrated Design on System Reliability

The designation of the K209A05 as a "Power Module" rather than a discrete IGBT is a key aspect of its value proposition. An integrated module consolidates the power switching transistor and potentially other components like freewheeling diodes into a single, thermally efficient package. This design approach offers distinct advantages over using separate, discrete components.

Think of it like a pre-fabricated structural beam in a building versus assembling one on-site from individual planks. The factory-built beam is engineered with optimized connections and material interfaces for maximum strength and predictable performance. Similarly, the K209A05 module provides tightly matched thermal and electrical characteristics between its internal components. This inherent matching minimizes parasitic inductance and ensures more balanced current sharing, reducing localized hot spots and improving the device's resilience to electrical stress. For a design engineer, this integration simplifies the Gate Drive layout and thermal management, leading to a more predictable and reliable power stage, which is a cornerstone of robust high-efficiency power systems.

Frequently Asked Questions (FAQ)

What is the primary benefit of using a 600V-rated IGBT module like the K209A05?

Its primary benefit is providing a robust safety margin for power converters and motor drives connected to 230V mains, effectively handling voltage spikes without risking component failure.

How does the 15A current rating influence its ideal application?

The 15A rating makes the K209A05 ideal for controlling smaller AC motors, typically those under 2 HP (1.5 kW), and for use in other switched-mode power supplies where current demands are moderate.

Is the K209A05 suitable for high-frequency switching applications?

As a standard IGBT module, it is optimized for switching frequencies typically found in motor drives, which are generally below 20 kHz. Its performance is geared towards minimizing conduction losses in these applications rather than for very high-frequency operation where switching losses dominate.

What does the "Power Module" format imply for manufacturing and assembly?

The module format simplifies the assembly process by reducing the number of individual components to be placed on the PCB. It also provides a single, large surface for mounting to a heatsink, which streamlines thermal design and improves heat dissipation compared to multiple smaller discrete components.

Strategic Outlook for Industrial Automation

In the context of increasing automation in small-scale industrial and commercial equipment, components like the Vinco K209A05 serve a critical role. The demand for decentralized, compact, and reliable motor drives continues to grow. This module's focus on providing essential performance in a durable, integrated package aligns with the industry's need for cost-effective solutions that do not compromise on operational longevity. As system designers face pressure to increase power density while maintaining reliability, leveraging integrated power modules becomes a key strategy for achieving these competing goals efficiently.