Content last revised on January 12, 2026

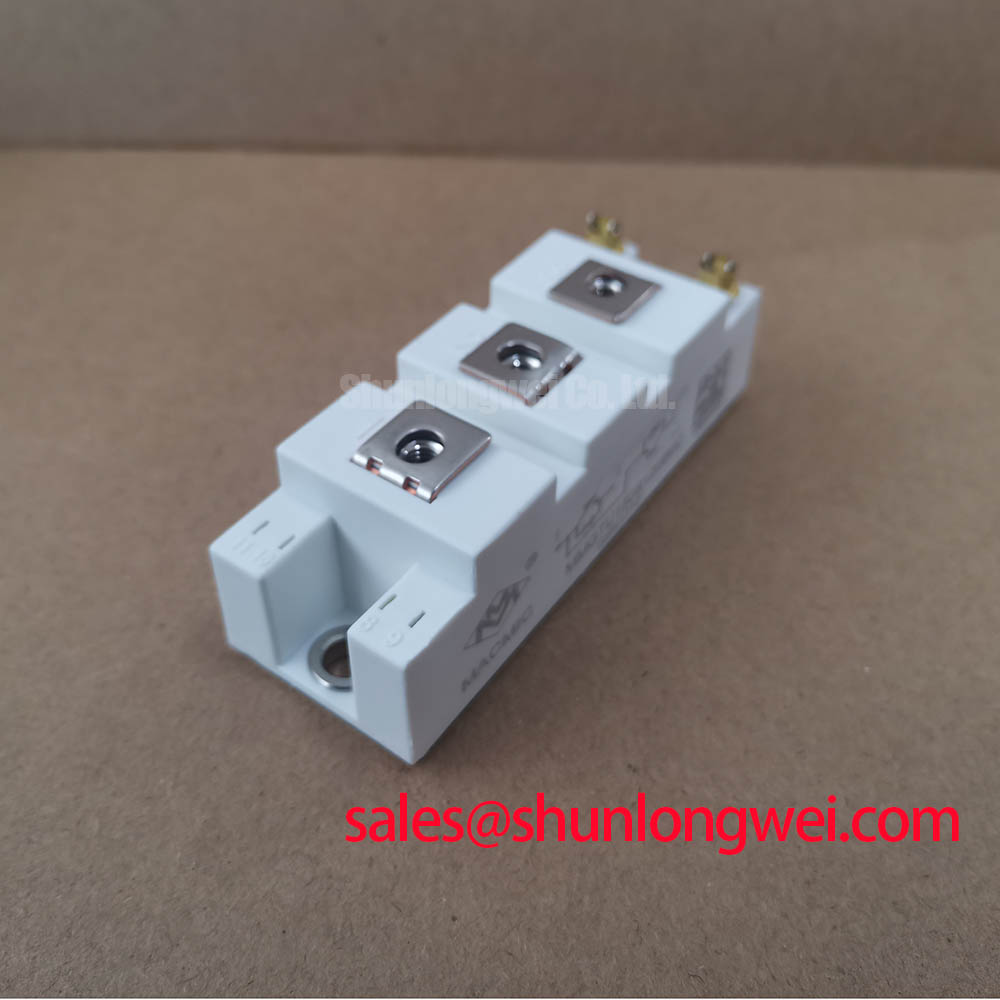

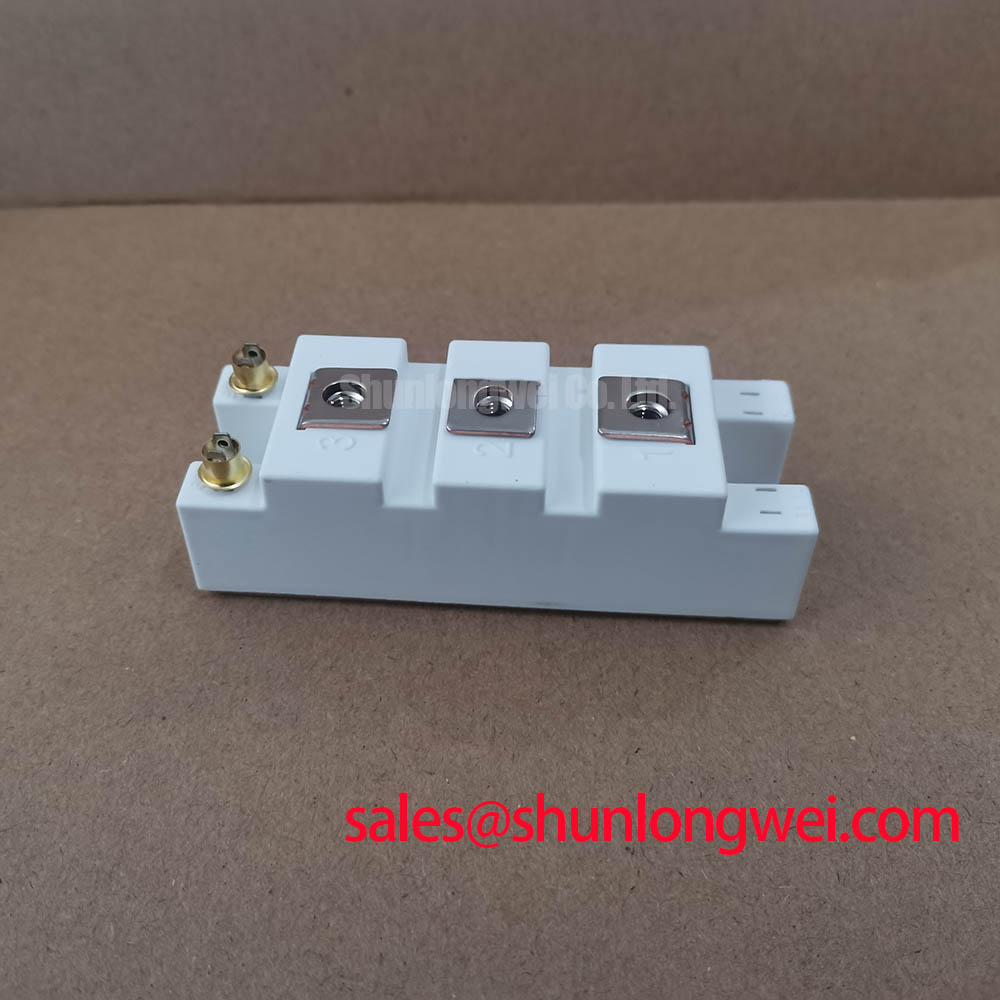

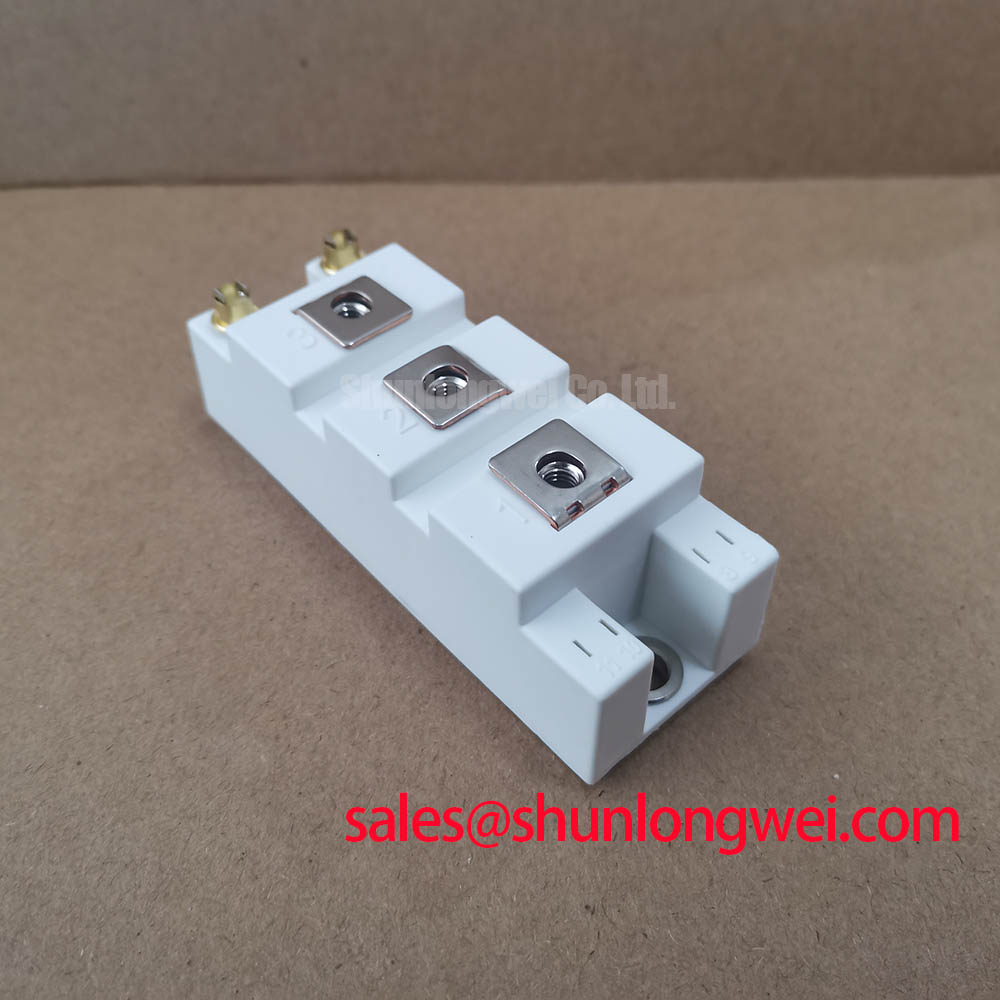

MacMic MMGTU150S120B6C | High-Integration 1200V PIM for Compact Motor Drives

The MacMic MMGTU150S120B6C is a high-performance Power Integrated Module (PIM) engineered to streamline the design of compact and efficient power conversion systems. By co-packaging a three-phase input rectifier, a brake chopper, and a three-phase inverter into a single, thermally optimized housing, this module offers a robust, all-in-one solution for engineers seeking to reduce system complexity, assembly time, and overall bill of materials (BOM).

- Core Specification: 1200V / 150A rating, providing ample power for a wide range of industrial applications.

- Integrated Topology: Features a full Converter-Inverter-Brake (CIB) configuration, ideal for AC motor control and regenerative applications.

- Advanced Chip Technology: Utilizes low-loss Trench Field-Stop IGBTs and soft-recovery Free-Wheeling Diodes (FWDs) to maximize efficiency and minimize thermal load.

- Simplified Thermal Design: A single, isolated copper baseplate ensures excellent heat transfer to the heatsink, simplifying thermal management.

- Built-in Monitoring: Includes an integrated NTC thermistor for precise, real-time temperature sensing, enabling robust over-temperature protection.

Engineered for Efficiency in Demanding Power Conversion Systems

The highly integrated nature of the MMGTU150S120B6C makes it an exceptional choice for applications where power density and reliability are paramount. Its CIB topology directly maps to the functional requirements of modern power electronics, delivering tangible benefits across various systems.

- Variable Frequency Drives (VFDs): In motor control, this PIM serves as the complete power core. The integrated rectifier, brake, and inverter stages significantly reduce the parasitic inductance between components, leading to lower voltage overshoots during switching. This simplifies the design of Snubber Circuit networks and improves overall system reliability.

- Robotic and Servo Drives: Precision and dynamic response are critical in robotics. The compact and optimized layout of the MMGTU150S120B6C ensures a clean and efficient power stage, which is fundamental for the high-fidelity control loops required in robotic servo drives.

- Uninterruptible Power Supplies (UPS): For high-reliability UPS (Uninterruptible Power Supply) systems, this module's high integration level translates to fewer potential points of failure and a smaller overall system footprint, allowing for more power in less space.

Technical Deep Dive: The Synergy of Advanced Silicon and Integrated Design

The performance of the MacMic MMGTU150S120B6C is rooted in its advanced semiconductor technology and intelligent package design. The module leverages a sophisticated Trench Field-Stop IGBT structure. This technology creates a superior balance between conduction losses (a very low VCE(sat) ) and switching losses. For the design engineer, this directly translates to reduced power dissipation, allowing for smaller heatsinks or higher operational power output within the same thermal budget.

Beyond the silicon, the PIM architecture provides significant electrical advantages. Consolidating the entire power stage into one module standardizes the layout and minimizes stray inductances that are unavoidable in discrete designs. This controlled internal environment is a key reason why integrated IGBT modules often exhibit superior EMC performance and heightened robustness against transient voltage spikes, simplifying the engineer's design and qualification process.

MMGTU150S120B6C Key Electrical Characteristics

| Parameter | Value |

|---|---|

| Max Collector-Emitter Voltage (VCES) | 1200 V |

| Continuous Collector Current (IC) @ TC=80°C | 150 A (Inverter) |

| Collector-Emitter Saturation Voltage (VCE(sat)) @ IC=150A, Tj=125°C | 1.85 V (Typ.) |

| Topology | Three-Phase Rectifier + Brake Chopper + Three-Phase Inverter (CIB/PIM) |

| Short-Circuit Withstand Time (tSC) | ≥ 10 µs |

| Max Operating Junction Temperature (Tjmax) | 150 °C |

Engineer's FAQ: Getting the Most Out of the MMGTU150S120B6C

What are the primary thermal management considerations for a PIM like this?

Effective thermal management is crucial. The module's single, flat copper baseplate is designed for optimal heat transfer to a heatsink. It is critical to ensure the heatsink surface is perfectly flat (typically <50µm) and clean. Apply a high-quality Thermal Interface Material (TIM) evenly and at the manufacturer's recommended thickness. The integrated NTC thermistor should be connected directly to your controller's monitoring circuit to enable real-time temperature feedback for overload and fault protection strategies. Understanding these factors is key to unlocking the full IGBT thermal performance.

Does the integrated brake chopper have any specific gate drive requirements?

Yes, while part of the same module, the brake chopper's gate drive can be treated slightly differently. It is typically operated in a pulsed, low-duty-cycle mode to dissipate regenerative energy. The gate drive circuit must still deliver a clean, fast-rising pulse with sufficient current to fully charge the IGBT's input capacitance, ensuring low conduction losses. Most importantly, robust protection against parasitic turn-on is essential. This can be achieved with a strong pull-down resistor or an active Miller clamp, even for this less frequently switched part of the circuit. For any complex design, please contact our technical team for detailed application support.