Content last revised on January 22, 2026

SKKT273/16E Thyristor/Diode Module | Semikron | 1600V

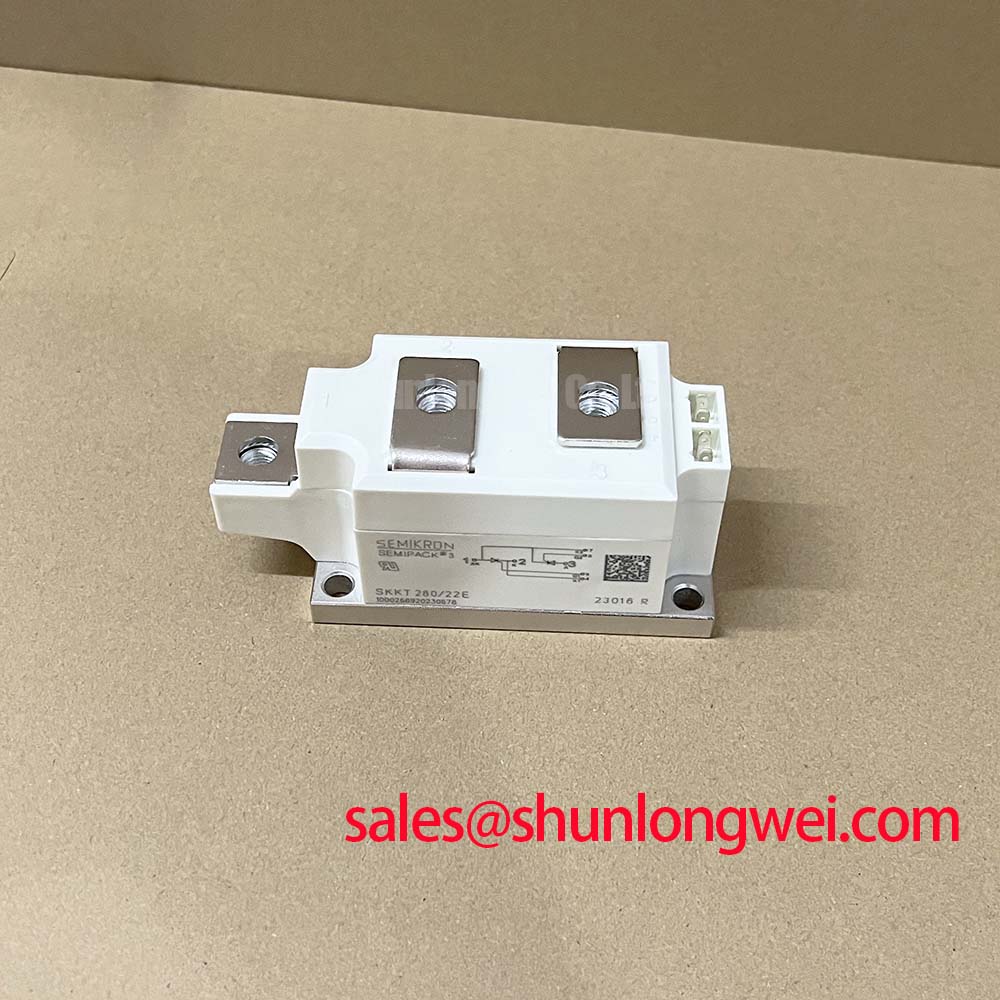

Introduction to the SKKT273/16E Power Module

The Semikron SKKT273/16E is a high-reliability thyristor/diode module engineered for superior thermal performance and extended operational life in demanding power control systems. It delivers robust power handling with key specifications of 1600V repetitive peak voltage, 275A average forward current, and an excellent thyristor thermal resistance of 0.08 K/W. This module's design provides two primary engineering benefits: enhanced thermal efficiency and exceptional long-term reliability. For engineers asking how to mitigate common module failure points, the SKKT273/16E's pressure contact technology directly addresses the challenge of solder fatigue, ensuring integrity through extensive thermal cycling.

Industry Insights & Strategic Advantage

Aligning with Industrial Demands for Uptime and Power Density

In modern industrial automation and heavy-duty power conversion, the emphasis is increasingly on maximizing system uptime and achieving higher power density. Equipment is expected to run longer, in more demanding thermal environments, without unscheduled maintenance. The architectural choices within a power module directly impact these goals. The SKKT273/16E, with its sophisticated thermal design, supports the trend of building more compact yet powerful systems. Its ability to efficiently transfer heat away from the semiconductor junctions allows designers to either push for higher output power or to optimize the cooling system for reduced size, weight, and cost, contributing to a lower total cost of ownership (TCO).

Technical Deep Dive

The Engineering Behind its Thermal and Mechanical Integrity

The performance of the SKKT273/16E is anchored in its internal construction, which prioritizes both thermal management and mechanical stability. Central to this design is its pressure contact technology. Unlike soldered modules, this approach eliminates a key wear-out mechanism—solder layer fatigue caused by repeated expansion and contraction during temperature changes. This results in a significantly higher power cycling capability and a more predictable operational lifespan.

Further enhancing its performance are several key features:

- Isolated Metal Baseplate: An Al2O3 ceramic insulator is hard-soldered to the baseplate, providing robust electrical isolation. This simplifies thermal design by allowing multiple modules to be mounted on a single, non-isolated heatsink, streamlining assembly and reducing potential points of failure.

- Glass Passivated Chips: The thyristor chips undergo glass passivation, a process that protects the sensitive junction termination area. This ensures stable blocking characteristics and low leakage currents, particularly at elevated operating temperatures, which is fundamental to long-term voltage-handling reliability.

Key Parameter Overview

Critical Specifications for System Evaluation

Evaluating the SKKT273/16E for a specific application requires a focus on its core electrical and thermal ratings. The following parameters are crucial for design calculations and system integration. Understanding the thermal resistance is particularly important; it acts like the width of a highway for heat, where a lower value (like this module's 0.08 K/W) signifies a wider, more efficient pathway for heat to escape the semiconductor junction.

| Parameter | Value |

|---|---|

| Repetitive Peak Off-State and Reverse Voltage (VDRM, VRRM) | 1600 V |

| Average On-State Current (ITAVM) @ Tc=85°C | 275 A |

| RMS On-State Current (ITRMS) | 430 A |

| Thermal Resistance, Junction to Case (Rth(j-c) per Thyristor) | 0.08 K/W |

| Mounting Force (Fm) | 20 ± 2 kN |

| Operating Junction Temperature Range (Tvj) | -40 to 130 °C |

Download the Complete SKKT273/16E Datasheet

Application Scenarios & Value

Where Robust Power Control is Paramount

The SKKT273/16E is engineered for high-current applications where precise control and operational durability are essential. Its electrical characteristics and robust thermal design make it a suitable component for a range of power conversion and control circuits. What is the key design benefit of its low thermal resistance? It allows for more compact heatsink solutions or higher current operation under stringent thermal constraints. For high-current rectifiers where minimizing heatsink size is critical, the SKKT273/16E's 0.08 K/W thermal resistance presents a distinct design advantage.

Primary application areas include:

- AC Motor Soft Starters: Provides controlled voltage ramping to reduce mechanical stress and inrush currents in large induction motors.

- Controlled Field Rectifiers: Used for regulating the field current of large generators and synchronous motors.

- Industrial DC Drives: Forms the core of the controlled rectifier stage for variable speed DC motor control.

- Temperature Control Systems: Suitable for high-power heating elements where phase-angle control is employed for precise temperature regulation.

Success Stories / Deployment Snippets

Field-Proven Topologies Enabled by the SKKT273/16E

While specific customer deployments are proprietary, modules with the capabilities of the SKKT273/16E are foundational to building resilient power systems. For instance, in three-phase controlled bridge rectifiers (B6C circuits) for industrial DC supplies, these modules provide the necessary voltage blocking and current handling for direct connection to 400V or 690V AC lines. Their proven pressure-contact design is particularly valued in systems like metal processing and mining, where equipment reliability directly translates to production output and operational safety. For more information on fundamental power module concepts, a review of how to decode power module datasheets can provide valuable context.

Intra-Series Comparison & Positioning

Positioning the SKKT273 Within the SEMIPACK 3 Family

The SKKT273/16E is part of Semikron's proven SEMIPACK 3 family, which offers a range of current and voltage ratings in a standardized industrial housing. The SKKT273/16E sits in a high-power segment of this series, offering a balanced combination of significant current capability and a 1600V blocking voltage rating. For systems requiring even higher current handling within a similar footprint, designers might evaluate the SKKH330/16E. Conversely, for applications with slightly lower power demands, the SKKT250/16E could be considered. The choice between these modules allows engineers to scale their power stage design precisely to the load requirements without significant mechanical redesigns.

Frequently Asked Questions

The primary advantage is enhanced long-term reliability. By eliminating solder layers between the chip and the baseplate, it drastically improves the module's resistance to thermal cycling fatigue, a common failure mode in high-power applications with fluctuating loads.

A 1600V rating provides a significant safety margin for applications operating on 400V or 480V AC lines, and it is essential for controlled rectifiers connected to 690V industrial grids. This higher blocking voltage capability enhances system robustness against line voltage transients. For a deeper understanding of thermal parameters, see this guide on why thermal resistance (Rth) matters.

Yes, the integrated Al2O3 ceramic provides sufficient electrical isolation for mounting onto a common, grounded heatsink in most industrial applications. This simplifies the mechanical and thermal design, but engineers must always ensure that system-level creepage and clearance requirements are met.

Yes, the SKKT273/16E contains two thyristors in a common cathode configuration, making it ideal for building one phase of an AC controller circuit (W3C). By using three such modules, a full three-phase AC-to-AC voltage controller can be implemented.

Future-Proofing Power Systems

As industrial systems become more integrated and demands for operational longevity increase, the intrinsic reliability of core power components like the SKKT273/16E becomes a strategic asset. Selecting a module built with technologies that inherently counter common wear-out mechanisms is a forward-looking design choice. It lays the groundwork for power conversion platforms that are not only powerful and efficient today but are also engineered to deliver sustained performance throughout an extended service life, ultimately enhancing the value and dependability of the end equipment.