Content last revised on November 20, 2025

SKM100GB123D: Engineering Analysis of a 1200V, 100A IGBT Module

Product Overview: Core Specifications and Strategic Value

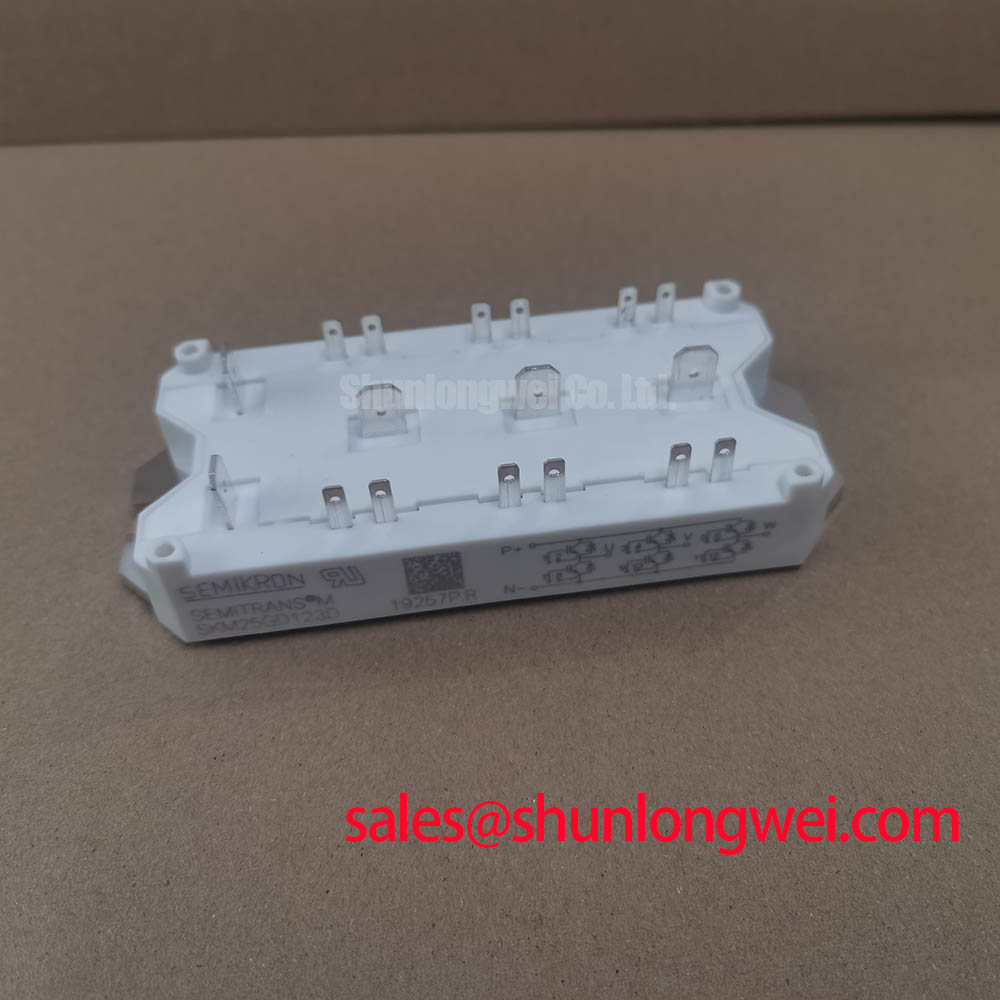

The Semikron SKM100GB123D is a SEMITRANS 2 dual IGBT module engineered for high-reliability power conversion systems. This device integrates two IGBTs in a half-bridge configuration, offering a robust solution for designers of motor drives and power inverters. It delivers a balanced performance profile optimized for efficient power switching. Core specifications include: 1200V VCES | 100A IC | 3.0V VCE(sat) (typ). Key engineering benefits are its low tail current with minimal temperature dependence and the inclusion of fast, soft-recovery inverse CAL diodes. This module directly addresses the challenge of achieving durable performance in demanding industrial applications by leveraging an isolated copper baseplate with Direct Copper Bonding (DCB) technology, enhancing thermal transfer and electrical insulation. For industrial drives operating on 400V/480V lines that require substantial design margin and proven reliability, the SKM100GB123D is a well-suited choice.

Key Parameter Overview

Decoding the Specs for Efficient Power Switching

The electrical and thermal characteristics of the SKM100GB123D are tailored for demanding power conversion applications. The highlighted parameters below are critical for system design, directly influencing efficiency, thermal management strategy, and operational robustness. Understanding these values is the first step in leveraging the module's full potential.

| Parameter | Symbol | Conditions | Value |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | - | 1200 V |

| Continuous Collector Current | IC | Tcase = 80 °C | 90 A |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 75 A, VGE = 15 V, Tj = 25 °C | 2.5 V (typ), 3.0 V (max) |

| Gate Threshold Voltage | VGE(th) | IC = 2 mA, VGE = VCE | 4.5 V (min), 6.5 V (max) |

| Total Power Dissipation | Ptot | Tcase = 25 °C, per IGBT | 500 W |

| Thermal Resistance, Junction-to-Case | Rth(j-c) | per IGBT | 0.25 K/W |

| Isolation Voltage | Visol | AC, 1 minute | 2500 V |

Download the SKM100GB123D datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Industrial Motor Control and Power Supplies

The SKM100GB123D is engineered for power systems where reliability and controlled switching are paramount. Its 1200V breakdown voltage provides a significant safety margin for applications connected to 400V and up to 575V AC lines, making it a robust choice for industrial Variable Frequency Drives (VFDs). A key engineering challenge in VFDs is managing the power losses during switching. The module's trench gate IGBT technology and integrated CAL freewheeling diodes are optimized to reduce these losses, directly contributing to higher drive efficiency and reduced heatsink requirements. For example, the "soft" recovery characteristic of the CAL diode minimizes voltage overshoots during turn-off, which mitigates EMI and reduces stress on the IGBT itself, enhancing system longevity. This makes it particularly suitable for servo drives, uninterruptible power supplies (UPS), and welding power supplies that demand both efficiency and durability. While this model is well-suited for 100A requirements, for systems needing higher current handling, the related SKM300GA123D offers a higher current rating within a similar voltage class.

Frequently Asked Questions (FAQ)

What is the primary benefit of the isolated copper baseplate with DCB technology?

The Direct Copper Bonding (DCB) technology provides superior thermal performance and high electrical isolation. It creates a direct, low-resistance path for heat to travel from the IGBT chip to the heatsink, which is critical for reliability. This is analogous to using a thermal paste with extremely high conductivity, ensuring the component runs cooler and extending its operational life under heavy loads.

How does the VCE(sat) of 3.0V (max) impact system design?

The Collector-Emitter Saturation Voltage, or VCE(sat), is the voltage drop across the IGBT when it is fully on. A lower VCE(sat) means lower conduction losses (Power Loss = VCE(sat) * IC). The 3.0V maximum value for the SKM100GB123D directly impacts the thermal design; engineers can calculate the heat generated during operation more accurately, allowing for right-sized heatsinks and a more compact, cost-effective overall system design.

Is the SKM100GB123D suitable for high-frequency switching applications?

Based on its datasheet characteristics, including turn-on and turn-off times, this module is optimized for applications in the lower to medium switching frequency range, typical for motor drives and UPS systems. While it features fast CAL diodes, its performance is balanced for low conduction losses, which are dominant in these applications. For very high-frequency designs (well above 20 kHz), designers should analyze the trade-off between switching and conduction losses carefully.

What does the "low tail current with low temperature dependence" feature mean for reliability?

Tail current occurs during the IGBT turn-off phase and is a source of switching loss. A low tail current, especially one that doesn't increase significantly with temperature, means more predictable and lower switching losses across the entire operating range. This stability is crucial for reliability in applications like IGBT-based inverters where temperatures can fluctuate, ensuring the device does not enter a thermal runaway condition.

What gate drive voltage is recommended for the SKM100GB123D?

The datasheet specifies a gate-emitter threshold voltage (VGE(th)) between 4.5V and 6.5V. However, to ensure the device is fully saturated (turned on) for minimal conduction losses, a gate voltage of +15V is typically recommended, as shown in the VCE(sat) test conditions. A negative gate voltage (e.g., -8V to -15V) during the off-state is also a standard practice to improve noise immunity and prevent accidental turn-on.

Technical Deep Dive

A Closer Look at CAL Diode and Thermal Design Integration

A standout feature of the SKM100GB123D is its integration of "CAL" (Controlled Axial Lifetime) freewheeling diodes. This isn't just a standard diode; it's specifically engineered for soft recovery. In a half-bridge circuit, when one IGBT turns on, it forces the diode paired with the other IGBT to turn off rapidly. This rapid turn-off in a standard diode can cause a sharp current drop, leading to significant voltage spikes and electromagnetic interference (EMI). The CAL diode's "soft" characteristic means this transition is smoother, like a car braking progressively rather than slamming on the brakes. This reduces electrical stress on the entire circuit and simplifies EMI filtering design. This feature, combined with the module's low thermal resistance (Rth(j-c) of 0.25 K/W), illustrates a design philosophy focused on system-level reliability. The low thermal resistance ensures that the heat generated, even during these controlled switching events, is efficiently evacuated from the semiconductor junction to the case, maintaining a lower operating temperature which is a cornerstone of long-term component life in power electronics.

Strategic Outlook

The SKM100GB123D embodies a design philosophy centered on robustness and predictable performance, key requirements for industrial-grade power conversion. As industrial automation and renewable energy systems demand higher efficiency and longer service life, components that offer a strong thermal foundation and controlled switching behavior become critical. This module's use of established technologies like DCB and CAL diodes provides a reliable, field-proven solution, enabling engineers to design systems that not only meet today's performance benchmarks but also adhere to long-term reliability standards essential for critical infrastructure like industrial motor controllers and UPS systems.