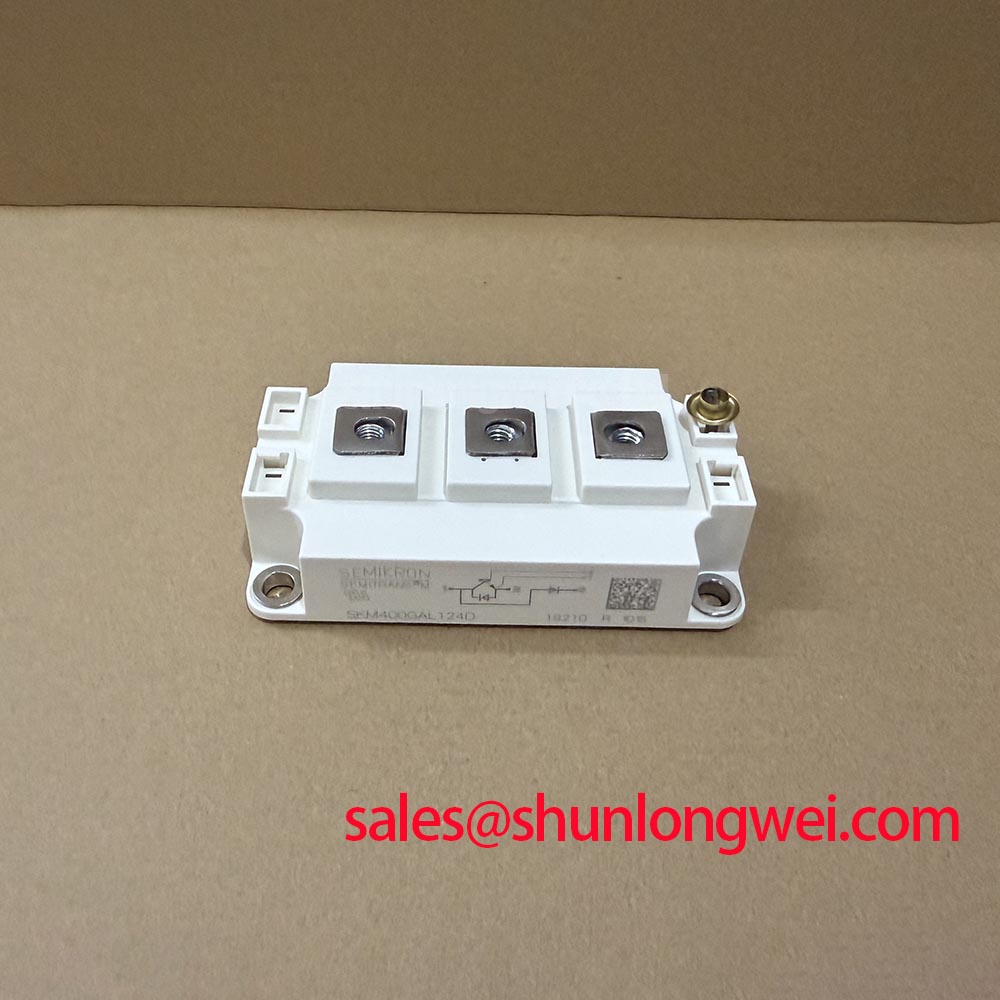

SKM400GAL124D IGBT: Low-Loss 1200V/400A Module Data

Engineered for exceptional switching efficiency, the SEMITRANS 2 SKM400GAL124D minimizes total power loss in high-frequency power conversion systems. This IGBT module leverages an advanced NPT IGBT structure and a fast, soft-recovery CAL freewheeling diode to deliver superior performance. Key specifications include: 1200V VCES | 400A ICnom | 2.1V VCE(sat) (typ). It offers tangible benefits such as reduced thermal management requirements and higher overall inverter efficiency. For designers questioning how to mitigate losses in systems operating above 10kHz, the SKM400GAL124D's low switching energy and optimized diode characteristics provide a direct engineering solution.

The following sections provide a detailed overview based on the official product datasheet to support your technical evaluation and design process.

Field-Proven Efficiency: Deployment Snapshots

While specific customer deployments are proprietary, the SKM400GAL124D's design characteristics make it a strong candidate for upgrading existing systems or for new, efficiency-focused designs. Consider a scenario involving a 150 kW industrial motor drive. By integrating a module like the SKM400GAL124D, which features a low typical VCE(sat) of 2.1V at nominal current, engineers can directly calculate a reduction in conduction losses compared to older generation IGBTs. This translates to lower operating temperatures and potentially smaller, less costly heatsink assemblies, contributing to a lower total cost of ownership over the system's lifecycle.

Powering High-Frequency Applications with Minimal Loss

The technical attributes of the SKM400GAL124D are precisely aligned with the demands of modern power conversion topologies where minimizing energy loss is a primary design driver. Its combination of low conduction and switching losses makes it an effective solution for a range of demanding applications.

- Variable Frequency Drives (VFDs): In motor control, higher switching frequencies allow for smoother current waveforms and reduced audible noise. The module's low Eon/Eoff values directly reduce the heat generated during these fast transitions, improving system reliability.

- Solar Inverters: Maximizing the energy harvested from photovoltaic arrays requires inverters with the highest possible efficiency. The low saturation voltage and fast CAL diode ensure that minimal power is wasted during the DC-to-AC conversion process.

- Uninterruptible Power Supplies (UPS): For critical power systems, efficiency is key to reducing operating costs and thermal footprint. The SKM400GAL124D helps achieve higher efficiency ratings, ensuring dependable power with less energy waste.

- Welding Equipment: High-power welding supplies that rely on inverter technology benefit from robust, efficient switching components to control the welding arc precisely.

What is the primary benefit of its CAL diode technology? It provides a fast and soft reverse recovery, which minimizes voltage overshoots and electromagnetic interference (EMI). For systems where both high efficiency and robust thermal performance are paramount, the SKM400GAL124D's low thermal resistance (Rthjc) of 0.045 K/W per IGBT is the optimal choice for ensuring effective heat transfer.

Critical Specifications for Efficiency-Centric Designs

The performance of the SKM400GAL124D is defined by a set of parameters optimized for low-loss operation. Below is a selection of key metrics from the datasheet that are central to its application value.

| Parameter | Condition | Value |

|---|---|---|

| Collector-Emitter Voltage (VCES) | Tj = 25 °C | 1200 V |

| Nominal Collector Current (ICnom) | - | 400 A |

| Collector-Emitter Saturation Voltage (VCE(sat)) | VGE = 15 V, IC = 400 A, Tj = 125 °C | 2.5 V (typ.) |

| Turn-on Switching Energy (Eon) | IC = 300 A, Tj = 125 °C | 36 mWs (typ.) |

| Turn-off Switching Energy (Eoff) | IC = 300 A, Tj = 125 °C | 42 mWs (typ.) |

| Thermal Resistance, Junction-to-Case (Rthjc) | per IGBT | 0.045 K/W |

Download the complete Datasheet for full specifications and characteristic curves.

Interpreting the Data

VCE(sat): The Collector-Emitter Saturation Voltage is a direct indicator of conduction losses. Think of it as the electrical "friction" the current encounters when the IGBT is fully on. The SKM400GAL124D's low typical value of 2.1V means less power is converted into heat during the on-state, a critical factor for overall system efficiency. For systems requiring even higher current handling, the related SKM600GA124D offers a 600A capability within a similar voltage class.

Switching Energy (Eon & Eoff): These values quantify the energy lost during the turn-on and turn-off transitions. In applications like VFDs or solar inverters that switch thousands of times per second, these small per-cycle losses add up significantly. The module's specified switching energies enable engineers to accurately model and manage total Switching Loss, which is essential for optimizing the thermal design.

Data for Your Design: SKM400GAL124D vs. Alternatives

To aid in the component evaluation process, this section presents a factual comparison based on typical datasheet values. This data is intended to empower your design decisions by highlighting key performance trade-offs without making direct recommendations.

Scenario: High-Frequency Inverter Stage Design

- SKM400GAL124D: This module is characterized by its NPT IGBT technology combined with a CAL (Controlled Axial Lifetime) freewheeling diode. This design focuses on achieving very low tail currents and fast, soft diode recovery, which are beneficial for reducing switching losses and EMI.

- Alternative Generic IGBT Module: Many standard modules may prioritize a lower VCE(sat) at the expense of higher switching losses (Eon/Eoff) or may feature diodes with slower, less "soft" recovery characteristics. This can lead to increased voltage stress on the switch and higher EMI generation.

An engineer's selection process would involve calculating the total power loss (conduction + switching) based on the specific operating frequency and duty cycle of their application. The SKM400GAL124D is positioned to show a distinct advantage in applications where switching losses are the dominant component of total power dissipation. For a deeper understanding of IGBT technologies, our guide to power semiconductor selection provides further context.

Technical Inquiries on the SKM400GAL124D

Here are answers to common engineering questions regarding this IGBT module.

1. What does the "CAL" designation for the freewheeling diode signify?

CAL stands for "Controlled Axial Lifetime," a technology used by Semikron to create freewheeling diodes with a "soft" recovery characteristic. This means the diode current falls smoothly during turn-off, reducing induced voltage spikes (V=L*di/dt) and minimizing electromagnetic interference (EMI). This is particularly valuable in high-frequency designs where sharp transitions can create system-level noise issues.

2. How does the NPT IGBT structure impact performance?

The Non-Punch-Through (NPT) IGBT design provides a positive temperature coefficient for VCE(sat). This characteristic simplifies the process of paralleling IGBT modules, as a device that heats up will naturally conduct slightly less current, promoting better current sharing among parallel modules without thermal runaway.

3. What is the typical gate drive voltage recommended for this module?

While the absolute maximum VGES is ±20V, the datasheet specifies characteristic performance at a VGE of +15V for turn-on and recommends a negative voltage (e.g., -5V to -15V) for a secure turn-off. Using a negative gate voltage ensures a higher immunity to noise-induced turn-on, which is a common field issue in high-power inverter environments.

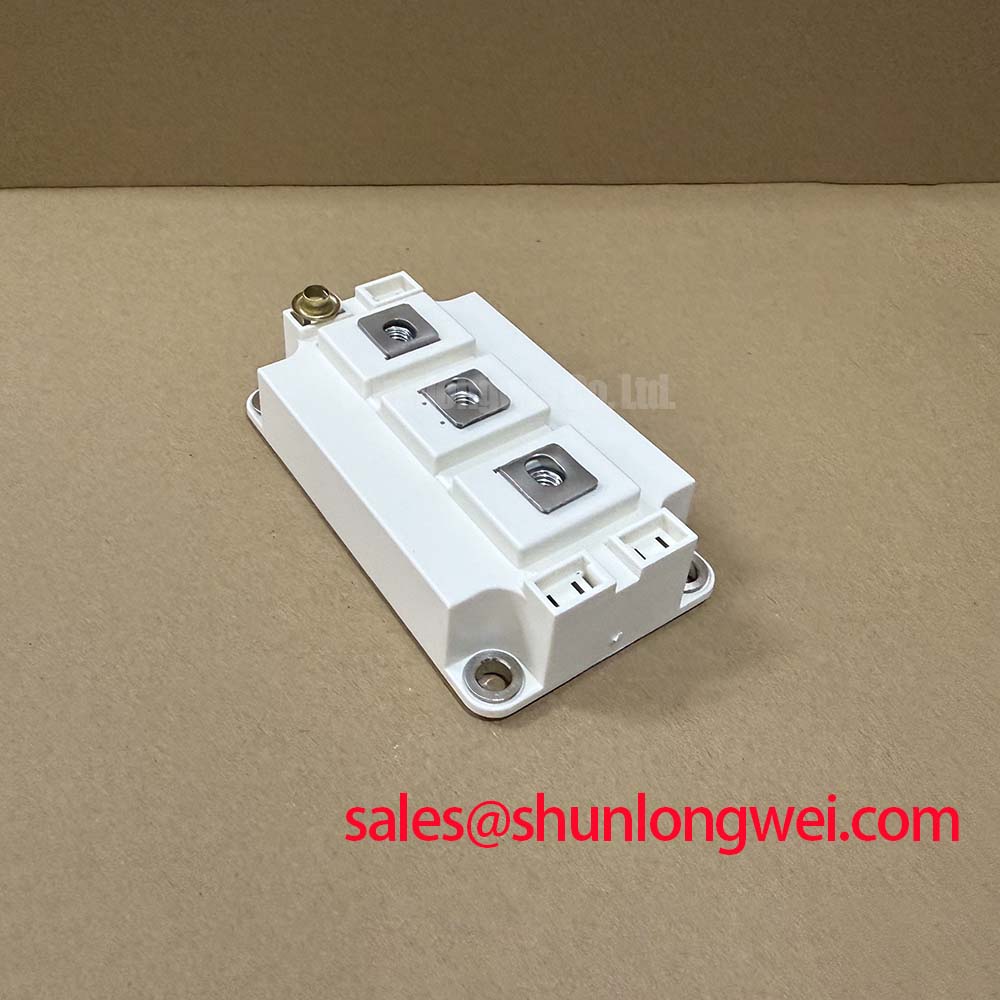

4. Is the copper baseplate isolated?

Yes, the SKM400GAL124D features an isolated copper baseplate utilizing Direct Copper Bonding (DCB) technology. This provides excellent thermal transfer to the heatsink while ensuring high electrical isolation between the power circuit and the mounting surface, simplifying the overall mechanical and thermal design of the system.

Anatomy of Low-Loss Performance: IGBT and Diode Technology

The efficiency of the SKM400GAL124D is not the result of a single feature but a synergy between its core components. The module integrates a Non-Punch-Through (NPT) IGBT with a complementary CAL freewheeling diode, a combination engineered specifically for balanced performance in hard-switching applications. The NPT structure is known for its ruggedness and wide Safe Operating Area (SOA), providing a robust foundation for the switch. How does this module achieve low tail current? Its homogeneous silicon structure inherently limits the tail current, which is a source of turn-off losses, and makes this behavior less dependent on temperature.

The inverse freewheeling diode is equally critical. Its fast recovery time and soft recovery behavior work in concert with the IGBT. When the IGBT turns on, the diode must turn off quickly and smoothly. A "snappy" or abrupt diode recovery can cause significant voltage overshoot and ringing. The CAL diode's design mitigates this, leading to a cleaner switching waveform, reduced stress on the IGBT, and lower EMI generation that might otherwise require additional filtering components.

The Strategic Value of Reduced Energy Consumption

Selecting an IGBT module based on efficiency is a strategic decision that extends beyond the component's initial cost. In an industrial landscape increasingly shaped by energy regulations and sustainability targets, the total cost of ownership (TCO) is paramount. The lower power losses of the SEMITRANS 2 SKM400GAL124D directly contribute to a more favorable TCO. This is achieved by reducing the direct cost of wasted electricity over years of operation and by decreasing the capital expenditure on thermal management hardware, such as oversized heatsinks and high-capacity cooling fans. As energy efficiency standards become more stringent for industrial equipment, incorporating high-efficiency modules like this one can be a key factor in ensuring product compliance and market competitiveness.

Future-Proofing Designs with High-Efficiency Power Stages

As industrial automation and renewable energy systems evolve, the demand for higher power density and lower operational expenditure will only intensify. The engineering choices made today in power stage design will determine a system's viability in this future landscape. By focusing on components like the SKM400GAL124D that are fundamentally optimized for low energy loss, designers are not just meeting current performance targets but are also aligning their products with long-term trends in energy conservation and sustainable technology. This forward-looking approach ensures that systems remain efficient, reliable, and compliant as industry standards continue to advance.