1. What is a thickness gauge

A thickness gauge is a gauge used to measure the thickness of materials and objects. In industrial production, it is often used to continuously or sample the thickness of products (such as steel plates, steel strips, films, paper, metal foils and other materials). There are radioactive thickness gauges that use the penetration characteristics of alpha rays, beta rays, and gamma rays; there are ultrasonic thickness gauges that use ultrasonic frequency changes; there are eddy current thickness gauges that use the principle of eddy current; and they use the principle of mechanical contact measurement. Thickness gauge, etc.

2. Working principle of thickness gauge

The laser thickness gauge is generally composed of two laser displacement sensors up and down. The upper and lower sensors respectively measure the position of the upper surface and the lower surface of the measured body, and the thickness of the measured body is obtained by calculation.

3. Classification of thickness gauges

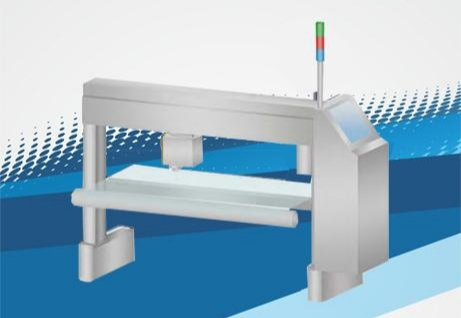

1) Laser thickness gauge

It uses the principle of laser reflection to measure the thickness of the product according to the light section method to measure and observe the microscopic geometry of the machined surface of the parts. It is a non-contact dynamic measuring instrument. It can directly output digital signals and connect with industrial computers, and quickly process data and output deviation values to various industrial equipment.

2) X-ray thickness gauge

When using X-rays to penetrate the material to be measured, the change in the intensity of X-rays is related to the thickness of the material to determine the thickness of the material. It is a non-contact dynamic measuring instrument. It takes PLC and industrial computer as the core, collects calculation data and outputs the target deviation value to the rolling mill thickness control system to achieve the required rolling thickness. Main application industries: non-ferrous metal strip and foil processing, metallurgical industry strip processing.

3) Paper thickness gauge

It is suitable for measuring the thickness of various films, paper, cardboard and other sheet materials below 4mm.

4) Film thickness gauge

It is used to measure the thickness of thin films, sheets and other materials. It has a wide measurement range and high measurement accuracy. It has the characteristics of data output, zero setting at any position, metric and inch conversion, automatic power-off and so on.

5) Ultrasonic thickness gauge

Ultrasonic thickness gauge is based on the principle of ultrasonic pulse reflection for thickness measurement. When the ultrasonic pulse emitted by the probe reaches the material interface through the measured object, the pulse is reflected back to the probe, which is determined by accurately measuring the time the ultrasonic wave travels in the material. The thickness of the material being measured. This principle can be used to measure all kinds of materials that can make ultrasonic waves propagate in its interior at a constant speed. It is suitable for measuring the thickness of metals (such as steel, cast iron, aluminum, copper, etc.), plastics, ceramics, glass, glass fibers and any other good conductors of ultrasonic waves.

6) Coating thickness gauge

The coating thickness gauge uses electromagnetic induction to measure the thickness of the coating. The probe on the surface of the component produces a closed magnetic Circuit. As the distance between the probe and the ferromagnetic material changes, the magnetic circuit will change to varying degrees, causing changes in the magnetoresistance and the inductance of the probe coil. This principle can be used to accurately measure the distance between the probe and the ferromagnetic material, that is, the coating thickness.

The F-type probe of the coating thickness gauge can directly measure the thickness of the non-magnetic coating on the surface of the magnetic material (such as steel, nickel) (such as: paint, plastic, enamel, copper, aluminum, zinc, chromium, etc.). It can be used for thickness measurement of electroplating layer, paint layer, enamel layer, aluminum tile, copper tile, babbitt alloy tile, phosphate layer, paper, and thickness measurement of hull paint and attachments to underwater structures.