Content last revised on January 20, 2026

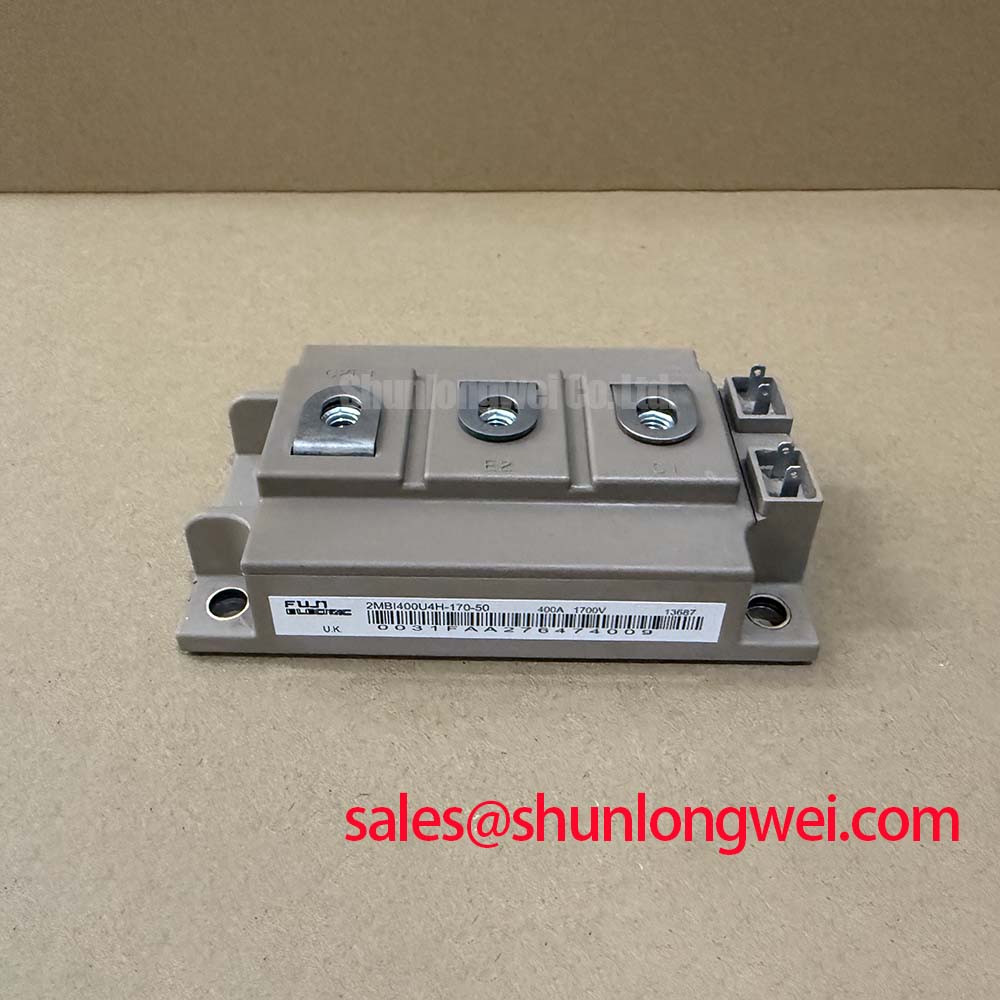

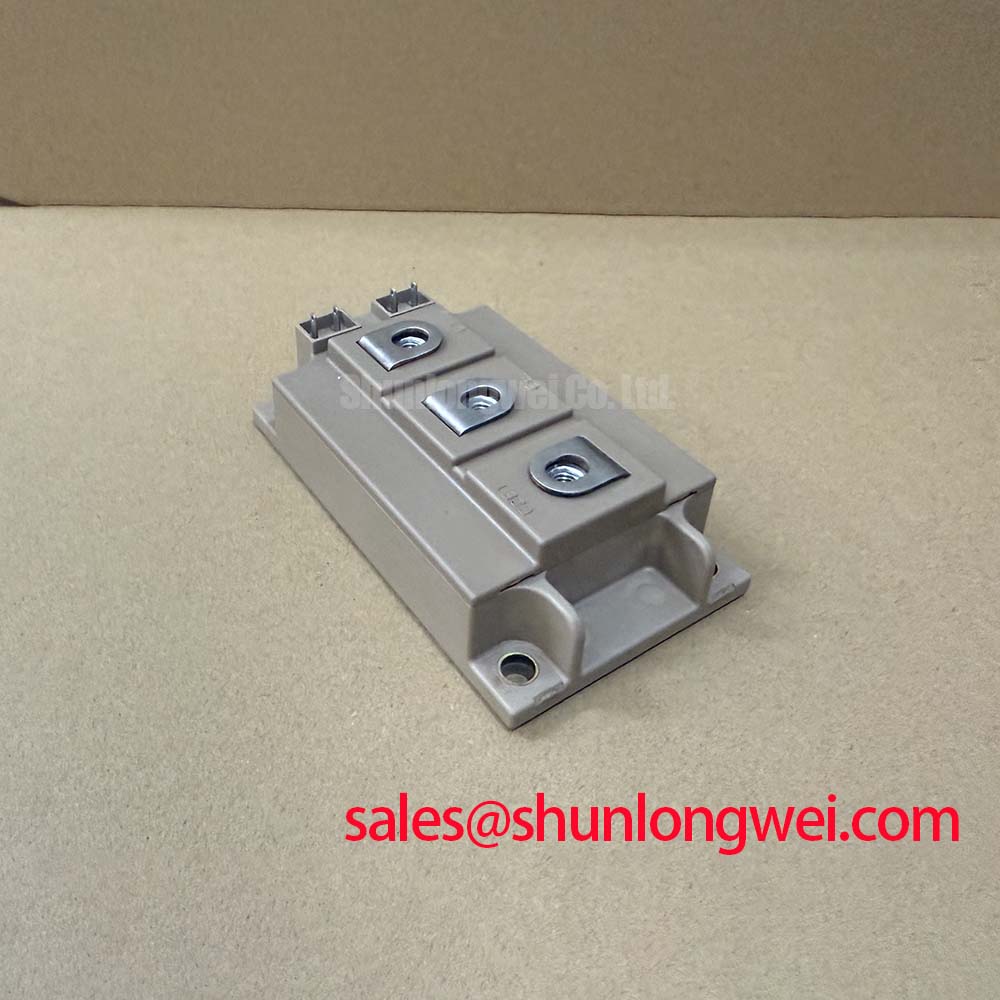

2MBI400U4H-170-50: IGBT Module for High-Efficiency Inverters

Fuji Electric 2MBI400U4H-170-50: A Deep Dive into V-Series Performance

Engineered for high-power conversion systems, the Fuji Electric 2MBI400U4H-170-50 IGBT module leverages advanced V-Series technology to deliver exceptional efficiency and thermal stability. With its core specifications of 1700V, 400A, and a low collector-emitter saturation voltage (VCE(sat)) of 2.20V, this module is built to minimize both conduction and switching losses. This design focus translates directly into reduced cooling requirements and enhanced system reliability. For engineers grappling with stringent efficiency targets, its construction offers a clear path to reducing operational energy waste by ensuring more power is delivered to the load and less is dissipated as heat.

< B4>

Comparative Data for Informed Decision-Making

To support your system design and component evaluation process, the following table presents a factual comparison of key parameters. This data is intended to provide a clear, side-by-side view for engineering assessment without implying direct interchangeability. System-level testing is always necessary to validate performance in a specific application.

| Parameter | Fuji Electric 2MBI400U4H-170-50 | Alternative Model Example |

|---|---|---|

| Collector-Emitter Voltage (Vces) | 1700V | 1700V |

| Continuous Collector Current (Ic) at Tc=80°C | 400A | 450A |

| Collector-Emitter Saturation Voltage (VCE(sat)) Typ. at Tj=125°C | 2.20V | 2.15V |

| Total Switching Loss (Ets) Typ. at Tj=125°C | 160 mJ | 175 mJ |

| Thermal Resistance, Junction to Case (Rth(j-c)) per IGBT | 0.086 °C/W | 0.080 °C/W |

Note: The "Alternative Model Example" represents typical values for a comparable market component. Always refer to the official datasheet for the specific part number you are considering.

Technical Analysis: Inside the V-Series Advantage

The performance of the 2MBI400U4H-170-50 is fundamentally rooted in Fuji Electric's 7th-generation "V-Series" trench gate field-stop IGBT technology. This silicon-level innovation is engineered to optimize the trade-off between conduction losses and switching losses, a critical factor in high-frequency power conversion. What is the main benefit of its V-Series chip? It achieves a lower VCE(sat) without significantly increasing switching energy, enhancing overall efficiency.

A key parameter for understanding conduction losses is the Collector-Emitter Saturation Voltage (VCE(sat)), specified at a typical value of 2.20V at a junction temperature of 125°C. This low voltage drop during the on-state is analogous to reducing friction in a mechanical system; it directly minimizes the power converted into waste heat while the device is conducting current. This characteristic is crucial for applications that operate with high duty cycles, as it significantly impacts the thermal load on the heatsink and the entire enclosure. For systems with demanding power density targets, a lower VCE(sat) is a direct enabler of more compact and cost-effective thermal management solutions.

Application Focus: Powering Demanding Industrial Systems

The robust electrical characteristics and high efficiency of the 2MBI400U4H-170-50 make it a strong candidate for a range of high-power industrial applications where reliability and energy conservation are paramount.

- High-Power Motor Drives: In large-scale Variable Frequency Drives (VFDs) for industrial motors, pumps, and fans, the module's low losses contribute to higher overall drive efficiency, reducing operating costs over the system's lifetime.

- Renewable Energy Inverters: The 1700V rating provides substantial design margin for large-scale solar inverters and wind turbine converters connected to higher voltage DC buses, enabling efficient and reliable grid integration.

- Uninterruptible Power Supplies (UPS): For data centers and critical industrial processes, the module ensures efficient power conversion in high-capacity UPS systems, minimizing energy waste during both normal operation and battery backup modes.

For high-power inverter designs where minimizing total power loss is more critical than achieving the absolute lowest conduction loss, this module's balanced switching and VCE(sat) profile makes it a highly effective choice.

Strategic Perspective: Efficiency as a Competitive Edge

In today's industrial landscape, efficiency is not merely a technical specification; it is a strategic imperative. The push towards carbon neutrality and increasingly stringent energy regulations places immense pressure on system designers to minimize power losses. The Fuji Electric 2MBI400U4H-170-50 directly addresses this trend. By integrating this module, engineering teams can develop power conversion platforms that not only meet but exceed efficiency standards. This translates into a tangible competitive advantage, offering end-users lower total cost of ownership (TCO) through reduced electricity consumption and potentially smaller, less expensive cooling systems. The V-Series technology within this module is a key enabler for next-generation systems that must deliver more power with a smaller environmental and financial footprint, a core principle in modern power electronics design.

Deployment Scenario: Upgrading a 250 kW VFD

Consider a scenario where an engineering team is tasked with upgrading a 250 kW industrial motor drive to meet a new, higher efficiency target. The existing design suffers from thermal limitations at peak loads, forcing performance derating. By selecting the 2MBI400U4H-170-50, the team leverages its lower total switching losses (Ets) and optimized VCE(sat). This swap results in a measurable reduction in waste heat, allowing the drive to operate at its full rated power without exceeding thermal limits. The improved efficiency not only satisfies the new standard but also enhances the product's marketability by offering customers significant long-term energy savings.

Highlighted Technical Specifications

The following parameters are central to the performance of the 2MBI400U4H-170-50. For a complete list of specifications, please refer to the official datasheet.

| Parameter | Value |

|---|---|

| Max. Collector-Emitter Voltage (Vces) | 1700 V |

| Continuous Collector Current (Ic) @ Tc=80°C | 400 A |

| Max. Collector-Emitter Saturation Voltage (VCE(sat)) @ Tj=125°C | 2.70 V |

| Total Switching Loss (Ets) Typ. @ Tj=125°C | 160 mJ |

| Max. Junction Temperature (Tj op) | 150 °C |

| Short Circuit Withstand Time (tsc) | 10 µs |

Download the Datasheet for comprehensive technical information.

Frequently Asked Questions (FAQ)

What is the primary benefit of the 1700V rating in the 2MBI400U4H-170-50?

The 1700V collector-emitter voltage (Vces) provides a significant safety margin for systems operating on high-voltage DC buses, such as 1000Vdc solar applications or industrial drives running on 690Vac lines. This robust blocking capability enhances system reliability by protecting against voltage transients and spikes that can occur on the power line.

How does the V-Series technology in this module affect thermal design?

Fuji Electric's V-Series technology is designed to reduce total power losses. By minimizing both the heat generated during conduction (low VCE(sat)) and switching, the module imposes a lower thermal load on the cooling system. This allows engineers to potentially use smaller, more cost-effective heatsinks or increase the power density of the overall inverter design without risking overheating.

Is this module suitable for paralleling to achieve higher current output?

Yes, IGBT modules like the 2MBI400U4H-170-50 are often designed for parallel operation. However, successful paralleling requires careful engineering, particularly in the gate drive circuit and physical busbar layout, to ensure balanced current sharing. The datasheet provides guidance on characteristics like the positive temperature coefficient of VCE(sat), which is essential for stable thermal behavior in parallel configurations. For further reading, explore this guide on decoding IGBT datasheets for critical parameters.

For systems that require different current or voltage ratings, related components such as the 2MBI300U4H-170 may offer alternative performance points for consideration in your design evaluation.

The strategic deployment of high-efficiency components like the 2MBI400U4H-170-50 is pivotal for advancing power conversion technology. As industries move toward greater electrification and stricter energy standards, the underlying semiconductor technology becomes the foundation for innovation, enabling more powerful, compact, and sustainable systems for the future.