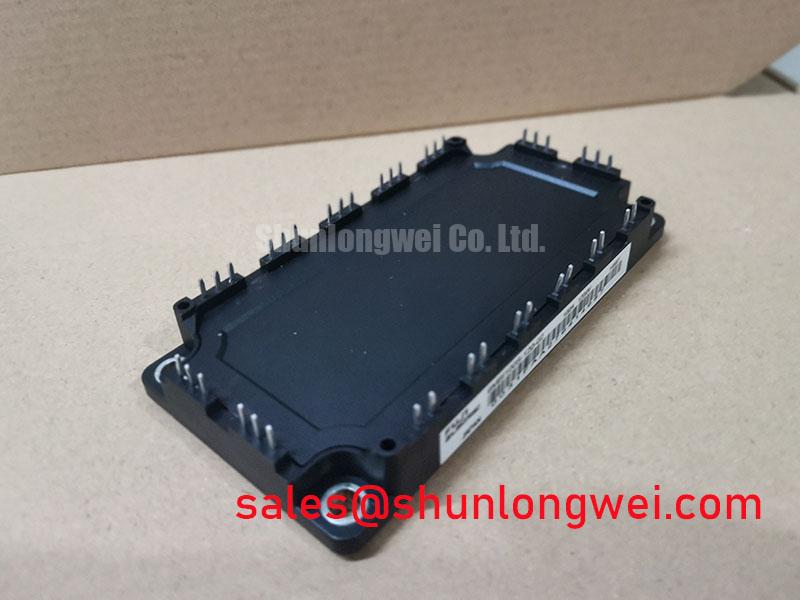

Fuji Electric 6MBI100S-120-02 | Robust 1200V/100A 6-Pack IGBT for Industrial Motor Drives

The Fuji Electric 6MBI100S-120-02 is a classic workhorse in the world of power electronics, engineered for durability and consistent performance in demanding industrial applications. As a 6-pack Power Integrated Module (PIM), it integrates a three-phase inverter bridge into a single, compact package. This design provides engineers with a reliable and streamlined solution for developing mid-power motor controllers, uninterruptible power supplies, and general-purpose inverters where operational robustness is paramount.

Key Parameter Overview

This module's specifications are tailored for high-reliability industrial power conversion. The electrical and thermal characteristics ensure stable operation under challenging load conditions. For a comprehensive list of specifications, you can Download the 6MBI100S-120 Datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1200V |

| Continuous Collector Current (IC) @ TC=80°C | 100A |

| Collector-Emitter Saturation Voltage (VCE(sat)) typ. @ IC=100A | 2.2V |

| Total Power Dissipation (PC) per IGBT | 310W |

| Operating Junction Temperature (Tj) | -40°C to +150°C |

| Configuration | 6-Pack (Three-Phase Bridge) |

Application Scenarios & Engineering Value

The architecture of the 6MBI100S-120-02 provides distinct advantages across several core industrial applications, making it one of the foundational IGBT modules for system designers.

- Variable Frequency Drives (VFDs): In VFDs for AC induction motors, this module's integrated 6-pack configuration drastically simplifies the power stage layout. It reduces component count, minimizes parasitic inductance, and provides a thermally efficient core for converting DC bus voltage into a variable frequency AC output, directly enabling precise motor speed control. This is central to the operation of high-efficiency inverter ACs.

- Servo Drives: For precision motion control, servo drives demand predictable and fast-responding power components. The controlled switching characteristics and integrated free-wheeling diodes (FWDs) of the 6MBI100S-120-02 ensure efficient handling of the regenerative energy from motor braking, contributing to the high-dynamic performance required in robotics and CNC machinery.

- Uninterruptible Power Supplies (UPS): The reliability of a UPS system hinges on its inverter stage. This module's robust thermal design and proven field reliability make it an excellent choice for online UPS systems, where it must sustain continuous power conversion with minimal losses and maximum uptime.

Technical Deep Dive: Core Strengths

While not the latest generation, the technology within the Fuji Electric 6MBI100S-120-02 is engineered for a balance of performance and ruggedness that remains highly relevant.

Optimized for Low-Frequency Conduction

The module features a low collector-emitter saturation voltage, VCE(sat), of 2.2V at its nominal current. In applications like motor drives, which often operate at switching frequencies below 10kHz, conduction losses are a dominant factor in overall efficiency. This low VCE(sat) directly translates into reduced power dissipation during the on-state, simplifying thermal design and improving system-level energy efficiency.

Integrated, High-Performance FWDs

Each IGBT in the module is paired with a co-packaged Free-Wheeling Diode (FWD). These diodes are not an afterthought; they are specifically optimized for motor control applications. They provide a robust path for the inductive current when an IGBT turns off, preventing catastrophic voltage spikes. Their soft recovery characteristics help to minimize electromagnetic interference (EMI), which simplifies the design of filtering and shielding in the final product.

Frequently Asked Questions (FAQ)

What are the key considerations for the gate drive circuit for the 6MBI100S-120-02?

To ensure reliable switching and prevent damage, a well-designed gate drive is critical. It is highly recommended to use a split power supply providing a +15V signal for decisive turn-on and full saturation, and a negative voltage (typically -5V to -15V) for turn-off. The negative bias provides a strong buffer against the Miller effect, preventing parasitic turn-on during high dv/dt events and enhancing noise immunity. For more detailed guidance, review these practical tips for robust IGBT gate drive design.

How critical is thermal management for this module?

Extremely critical. The specified 310W power dissipation is achievable only when the module is properly mounted to an adequate heatsink with the correct thermal interface material (TIM) and mounting torque. Poor Thermal Management will lead to excessive junction temperatures, drastically reducing the module's operational lifespan and potentially causing premature failure. Always design the thermal solution based on worst-case load and ambient temperature conditions. If you need assistance with thermal modeling for your specific application, feel free to contact our technical team.