Content last revised on January 21, 2026

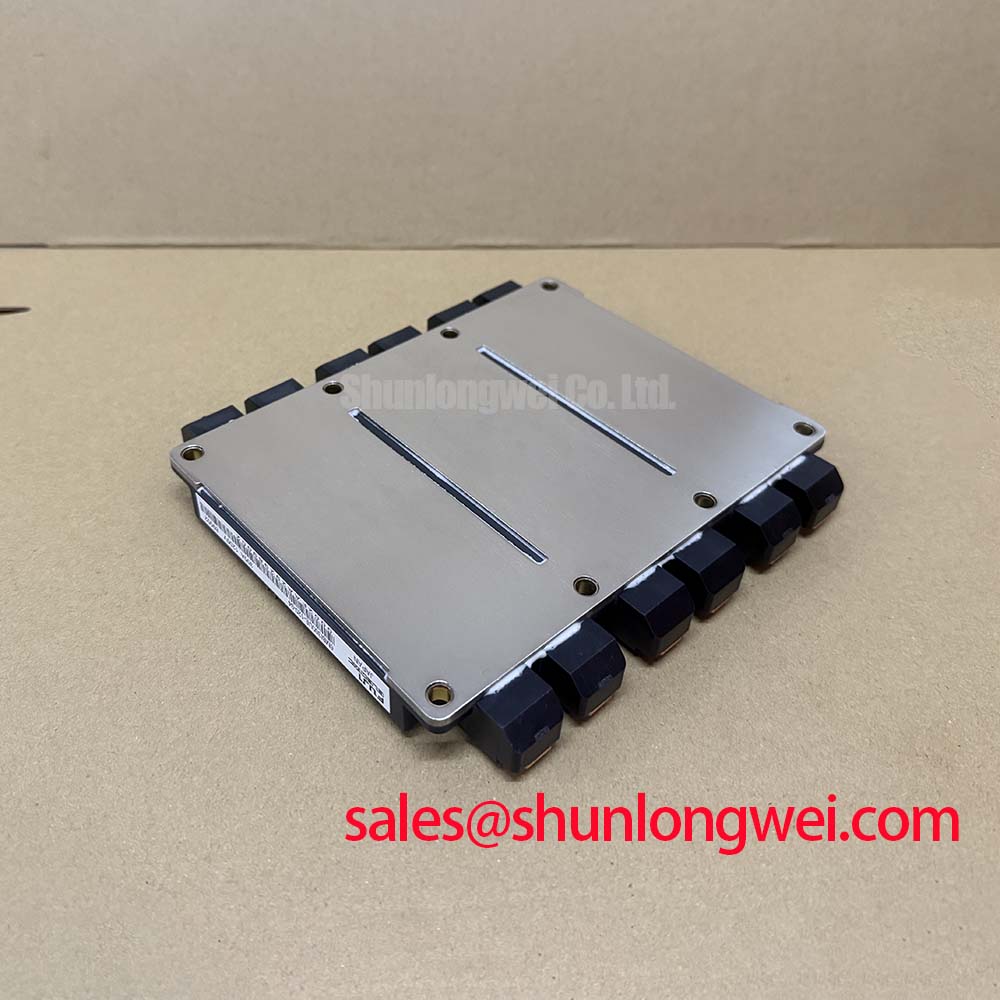

6MBI300UE-120-04 | 1200V 300A Low-Loss IGBT Module

Engineered for superior power conversion efficiency, the Fuji Electric 6MBI300UE-120-04 IGBT module provides a robust foundation for high-frequency power systems by minimizing total energy losses. At its core, the module's performance is defined by its Field-Stop (FS) trench gate technology, which achieves an optimal balance between conduction and switching performance. This design directly addresses the critical engineering challenge of how to reduce power dissipation in demanding applications, enabling more compact thermal management solutions and improving overall system reliability.

The Fuji Electric 6MBI300UE-120-04 is a 6-pack IGBT module from their U-Series, designed to deliver high efficiency and stable operation in a range of power conversion applications. Its architecture focuses on reducing the energy consumed during both on-state conduction and active switching phases, a key requirement for modern variable frequency drives and renewable energy systems. The module integrates six IGBTs in a three-phase bridge configuration, simplifying the power stage layout for motor control and inverter designs. Its construction ensures reliable performance under demanding thermal and electrical conditions.

For systems that require a higher current rating while maintaining similar voltage characteristics, the 6MBI450U-120 offers a 450A alternative within the same product family.

Datasheet Specifications for Low-Loss Performance

The performance of the 6MBI300UE-120-04 is best understood through its key datasheet parameters, which directly translate to tangible engineering benefits in power system design.

| Parameter | Value | Engineering Significance |

|---|---|---|

| Collector-Emitter Voltage (Vces) | 1200V | Provides a substantial safety margin for applications operating on 400V to 575V AC lines, ensuring robustness against voltage transients. |

| Continuous Collector Current (Ic) | 300A (at Tc = 80°C) | Enables high power output suitable for industrial motor drives and inverters in the 75 kW to 110 kW range. |

| Collector-Emitter Saturation Voltage (Vce(sat)) | 1.8V (typ) / 2.3V (max) | This low on-state voltage drop directly reduces conduction losses. Think of it as a water valve with very little resistance to flow; less energy is wasted as heat when the switch is fully on, improving overall efficiency. |

| Turn-off Switching Loss (Eoff) | 28 mJ/pulse (typ) | A low Eoff value is critical for minimizing switching losses, especially in systems operating at higher PWM frequencies. This allows for either higher frequency operation or significantly improved efficiency. |

| Short-Circuit Withstand Time (tsc) | ≥ 10µs | Defines the module's ability to survive a direct short-circuit event, a critical parameter for ensuring system ruggedness and preventing catastrophic failure. |

| Thermal Resistance (Rth(j-c)) | 0.08 K/W (per IGBT) | Indicates highly efficient heat transfer from the semiconductor junction to the case, simplifying heatsink design and ensuring the device operates within safe temperature limits. |

For complete specifications, please refer to the official 6MBI300UE-120-04 datasheet.

Comparative Analysis: Benchmarking the 6MBI300UE-120-04

To provide clear data for your design evaluation, the following table contrasts the 6MBI300UE-120-04 with another common 1200V IGBT module class. This data-centric view highlights the specific trade-offs related to efficiency and switching speed.

| Parameter | Fuji Electric 6MBI300UE-120-04 (U-Series) | Standard Speed 1200V/300A Module (Generic) |

|---|---|---|

| VCE(sat) (typ) at 25°C | 1.8V | ~2.1V |

| Total Switching Energy (Ets) (typ) | 50 mJ | ~65 mJ |

| Technology Focus | Balanced low VCE(sat) and low switching loss (FS Trench) | Often optimized for lower frequency, rugged applications |

This comparison illustrates that the 6MBI300UE-120-04 is optimized for lower total power loss, making it a strong candidate for applications where energy efficiency is a primary performance indicator.

Inside the FS Trench Gate: The Core of Switching Efficiency

The superior efficiency of the 6MBI300UE-120-04 stems from its advanced semiconductor design, specifically Fuji Electric's Field-Stop (FS) Trench Gate technology. What is the main benefit of FS Trench Gate design? It reduces both major types of power loss simultaneously. The trench gate structure lowers the on-state resistance, leading to a minimal VCE(sat) and therefore reduced conduction losses. Concurrently, the Field-Stop layer and thin wafer processing technologies optimize the carrier concentration during switching, which significantly curtails turn-on and turn-off losses (Eon and Eoff). This combination is crucial for achieving high efficiency in modern power converters that rely on high-frequency pulse-width modulation (PWM) strategies. For a more detailed look into how IGBTs function, explore our guide on the working principles of IGBTs.

Powering High-Efficiency Systems: Core Application Areas

The low-loss characteristics of the Fuji Electric 6MBI300UE-120-04 make it a prime component for systems where energy conservation and thermal performance are paramount. Its design provides distinct advantages across several key industrial sectors.

- Variable Frequency Drives (VFDs): In motor control, every percentage point of efficiency gain translates to significant energy savings over the equipment's lifetime. The module's low total losses reduce the heat dissipated in the drive cabinet, enabling more compact designs or operation in higher ambient temperatures.

- Solar Power Inverters: For renewable energy systems, maximizing the power delivered to the grid is the ultimate goal. The high efficiency of this IGBT module ensures that minimal energy generated by the solar panels is wasted as heat during the DC-to-AC conversion process.

- Uninterruptible Power Supplies (UPS): In critical power applications, high efficiency leads to lower operating costs and reduced battery drain during an outage. The module's reliability and low thermal signature contribute to building dependable UPS systems with a longer service life.

For high-frequency industrial drives where minimizing heat is more critical than raw switching speed, the 6MBI300UE-120-04's low VCE(sat) provides a clear advantage in thermal management.

Meeting Energy Mandates: The Strategic Value of Low-Loss IGBTs

The adoption of high-efficiency components like the 6MBI300UE-120-04 is no longer just a design choice but a strategic necessity. Global trends toward stricter energy efficiency standards for industrial equipment, such as the IE4 and IE5 classes for electric motors, compel engineers to minimize losses at every stage of the power conversion chain. By building systems around low-loss IGBTs, manufacturers can more easily meet these regulatory requirements, reduce the total cost of ownership (TCO) for their customers, and contribute to sustainability goals. The inherent efficiency of this module helps future-proof designs against the next wave of energy conservation mandates. Further reading on the role of IGBTs can be found in our overview of IGBTs in high-efficiency power systems.

Deployment Snapshot: Achieving Lower Operating Temperatures

An engineering team tasked with upgrading a 75 kW industrial pump drive serves as a practical example. By replacing an older generation IGBT module with the 6MBI300UE-120-04, the team documented a consistent 5°C reduction in the heatsink temperature under maximum load conditions. This thermal improvement was achieved without altering the existing cooling system, which provided the team with greater design margin and validated the long-term reliability benefits of using a module with lower intrinsic power losses.

Technical FAQ for the 6MBI300UE-120-04

1. How does the low VCE(sat) of the 6MBI300UE-120-04 impact thermal design?A lower VCE(sat) directly reduces conduction power loss (P = VCE(sat) * Ic). This means less heat is generated for the same amount of current, allowing for the use of a smaller, more cost-effective heatsink or providing a greater thermal operating margin with an existing cooling solution.

2. What is the recommended gate drive voltage for this IGBT module?Based on the datasheet, the recommended gate-emitter voltage (Vge) is typically +15V for turn-on and -15V for turn-off. Using a negative voltage for turn-off provides better immunity to noise and prevents unintended turn-on.

3. Can the 6MBI300UE-120-04 be connected in parallel for higher current output?Yes, IGBT modules like this can be paralleled. However, careful design is required to ensure proper current sharing. This includes symmetrical PCB layouts, the use of separate gate resistors for each module, and consideration of the positive temperature coefficient of VCE(sat) to prevent thermal runaway. For more information on this topic, see this application note on paralleling IGBTs.

4. What does the "U-Series" designation from Fuji Electric signify?The U-Series generally refers to Fuji Electric's universal, high-performance IGBTs featuring their trench gate and field-stop technology. These modules are designed to provide a well-balanced combination of low conduction losses and fast switching speed for a wide array of applications.

5. How do I calculate the total power loss for the 6MBI300UE-120-04 in my specific application?Total power loss is the sum of conduction losses and switching losses. Conduction loss is calculated using VCE(sat) and the load current profile. Switching losses (Eon and Eoff) are multiplied by the switching frequency. The datasheet provides the necessary curves and values to perform these calculations for your specific operating conditions.

Design Considerations for Future Optimization

When integrating the 6MBI300UE-120-04, system designers should look beyond immediate performance and consider long-term optimization. The module's low switching losses open the door to exploring higher PWM frequencies, which can lead to smaller and lighter magnetic components like inductors and transformers, further shrinking the overall system footprint. Moreover, the reduced thermal load not only simplifies the heatsink but also lessens the stress on other nearby components, contributing to an extended operational lifetime for the entire power converter. Capitalizing on these efficiency gains at the component level allows for significant innovation at the system level.