Content last revised on January 18, 2026

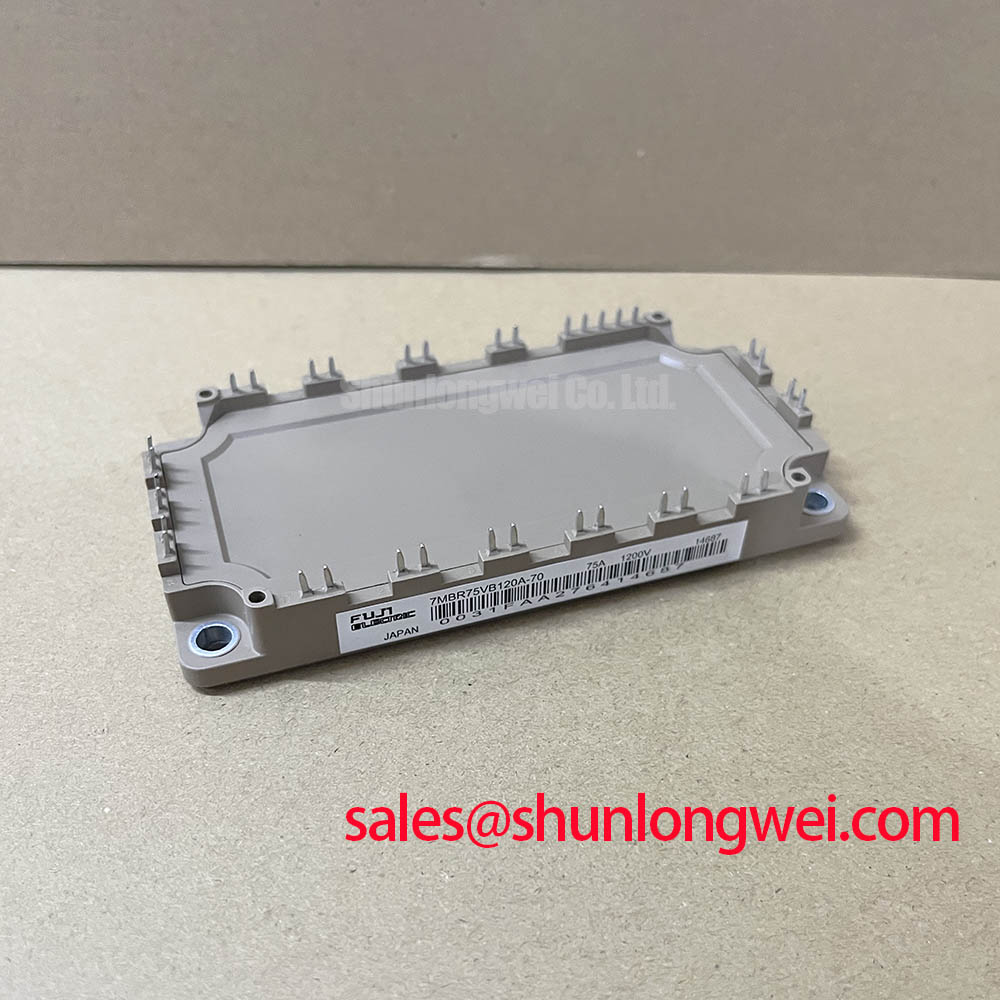

Fuji 7MBR75VB120A-70: Integrated 1200V/75A IGBT PIM

The Fuji Electric 7MBR75VB120A-70 is a V-Series Power Integrated Module (PIM) that embodies a significant step forward in power electronics design. At its core, this module is built on an advanced 7-in-1 topology, integrating a three-phase converter, a brake chopper, and a full three-phase inverter into a single, compact package. This high level of integration directly addresses a core challenge for power system engineers: how to simplify VFD design without compromising performance. By consolidating the entire power conversion stage, the 7MBR75VB120A-70 drastically reduces external component count, minimizes PCB complexity, and shrinks the overall system footprint, accelerating time-to-market for demanding applications.

Strategic Edge: How Integrated PIMs Accelerate Drive Development

In the push towards more compact and energy-efficient industrial automation, the design of the motor drive's power stage is paramount. The adoption of a highly integrated Power Integrated Module (PIM) like the 7MBR75VB120A-70 offers a distinct strategic advantage over discrete or lower-integration solutions. The primary benefit lies in the reduction of Total Cost of Ownership (TCO). While the initial component cost might be one consideration, the engineering value extends much further. A 7-in-1 module significantly cuts down on assembly costs, reduces the required PCB real estate, and simplifies procurement and inventory management. Furthermore, the close proximity of the internal components within a factory-optimized layout minimizes parasitic inductance, which is a common source of voltage overshoots and EMI issues in discrete designs. This allows designers to build more robust and reliable systems that can more easily meet stringent electromagnetic compatibility (EMC) standards. For more on the fundamentals of these devices, see our guide on IGBT modules as the backbone of power systems.

Critical Specifications for System Integration

Understanding the module's parameters is key to successful implementation. For a deeper dive into interpreting these values, consider reading our guide on decoding IGBT datasheets.

Inverter Section

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 1200 V |

| Collector Current (Ic) @ Tc=80°C | 75 A |

| Collector-Emitter Saturation Voltage (Vce(sat)) @ 75A | 2.35 V typ. |

| Power Dissipation (Pc) per device | 385 W |

Brake Section

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 1200 V |

| Collector Current (Ic) @ Tc=80°C | 35 A |

| Collector-Emitter Saturation Voltage (Vce(sat)) @ 35A | 2.50 V typ. |

| Power Dissipation (Pc) per device | 220 W |

Converter Section

| Parameter | Value |

|---|---|

| Repetitive Peak Reverse Voltage (Vrrm) | 1600 V |

| Average Output Current (Io) | 75 A |

| Forward Voltage (Vf) @ 75A | 1.5 V typ. |

Anatomy of the 7-in-1 V-Series Power Stage

The Fuji 7MBR75VB120A-70 is engineered using Fuji Electric's V-Series technology, which focuses on optimizing the trade-off between conduction and switching losses. This is achieved through advanced trench-gate structures and refined wafer processing. Here are a few key parameters and their engineering significance:

- VCE(sat) (Collector-Emitter Saturation Voltage): With a typical value of 2.35V at its nominal current, this parameter is a direct indicator of the energy lost as heat during the on-state. The low VCE(sat) of the V-Series ensures reduced conduction losses, contributing to higher overall efficiency of the motor drive and lessening the burden on the cooling system.

- Rth(j-c) (Junction-to-Case Thermal Resistance): This value represents the module's ability to transfer heat away from the active silicon chip to the baseplate. Think of it as the width of a pipe; a lower Rth(j-c) is like a wider pipe, allowing more heat to flow away easily. This superior heat dissipation strategy is critical for ensuring operational robustness and long-term reliability, especially under heavy load conditions.

- Integrated NTC Thermistor: The inclusion of a negative temperature coefficient (NTC) thermistor provides a direct, real-time method for monitoring the module's internal temperature. This feedback is essential for implementing precise over-temperature protection, preventing thermal runaway, and enabling predictive maintenance algorithms.

Sizing Your Power Stage: The 7MBR75VB120A-70 in Context

Selecting the right power module requires matching its capabilities to the application's demands. The 7MBR75VB120A-70, with its 1200V/75A inverter rating, is positioned for mid-power applications, typically motor drives in the 30 kW to 37 kW range operating on 380V to 480V AC lines. When evaluating alternatives, it's useful to consider other modules within the same family. For lower power requirements, the 7MBR50VP120-50 offers a 50A solution in a similar package, allowing for platform-based design where the same PCB and mechanical layout can be scaled across different power levels. For applications demanding slightly more current overhead, the 7MBR100VX120-50 provides a 100A alternative. The choice between these depends on the specific load profile, overload requirements, and the thermal design of the end system. The integrated approach of PIMs simplifies this scaling process compared to redesigning a complex discrete layout.

Deployment Blueprints: Real-World Use Cases

The highly integrated and efficient nature of the 7MBR75VB120A-70 makes it an excellent foundation for a variety of power conversion systems where space, reliability, and ease of assembly are key drivers. Its specifications are particularly well-suited for:

- Variable Frequency Drives (VFDs): For general-purpose industrial motors, fans, pumps, and conveyor systems, this module provides a complete power stage that simplifies manufacturing and enhances durability.

- AC and DC Servo Drive Amplifiers: In robotics and CNC machinery, precise control and compact design are essential. The module’s integrated structure supports the development of compact, high-performance servo drives.

- Uninterruptible Power Supplies (UPS): The combination of a rectifier and inverter in one package is ideal for building compact and efficient online UPS systems that protect critical loads.

Engineering Questions Answered

What is the primary benefit of the '7-in-1' configuration in the 7MBR75VB120A-70?

The main advantage is design simplification and system compactness. By integrating the input rectifier, brake chopper, and output inverter into one module, it eliminates the need for multiple discrete components and complex interconnects. This reduces assembly time, minimizes PCB space, lowers parasitic inductance, and improves overall system reliability and manufacturability.

What is the best way to utilize the integrated NTC thermistor for over-temperature protection?

The NTC thermistor should be connected to an analog input on your system's microcontroller. Create a lookup table or use the Steinhart-Hart equation to convert the measured resistance value into a precise temperature reading. This data should be used to implement two levels of protection: a warning threshold (e.g., 115°C) that might trigger a fan speed increase or a load reduction, and a hard-stop fault threshold (e.g., Tjop max of 150°C) that triggers an immediate shutdown of the IGBTs to prevent permanent damage.

To ensure your design is optimized for performance and longevity, contact our technical support team for detailed application notes and design-in assistance. Specify the Fuji Electric 7MBR75VB120A-70 in your next project to leverage the benefits of a fully integrated power solution from a leader in semiconductor technology, Fuji Electric.