Content last revised on January 18, 2026

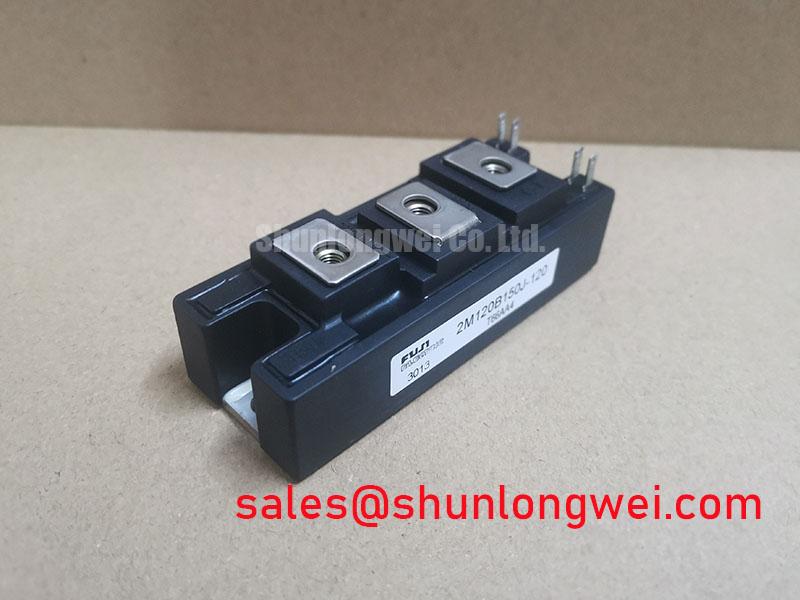

Fuji Electric 2MBI150SC-120 | Engineered for Enduring Performance in Power Conversion

The Fuji Electric 2MBI150SC-120 is a 1200V, 150A dual IGBT module renowned for its robustness and consistent performance in demanding industrial applications. As part of Fuji's S-Series, this module leverages proven Non-Punch-Through (NPT) technology to offer a balanced profile of switching efficiency, conduction loss, and exceptional durability. It represents a highly reliable solution for designers seeking to build or maintain power systems where longevity and operational stability are paramount.

Application Scenarios & Value Proposition

The Fuji 2MBI150SC-120 is not merely a component; it is a foundational building block for high-power systems that require unwavering reliability. Its electrical and thermal characteristics are optimized for the following core applications:

- Inverters for Motor Drives: In Variable Frequency Drive (VFD) applications, the module's high short-circuit withstand capability provides a crucial layer of protection against unexpected motor stalls or phase shorts. Its stable performance across a wide temperature range ensures consistent torque delivery and precise motor control.

- Uninterruptible Power Supplies (UPS): For mission-critical UPS systems, reliability is non-negotiable. The 2MBI150SC-120's NPT design provides a wide Safe Operating Area (SOA), ensuring it can handle the fluctuating load demands and transient conditions typical in backup power applications without degradation.

- AC and DC Servo Drives: The module's fast switching characteristics enable high-frequency operation, which is essential for the dynamic response and precision required in modern servo systems. The integrated half-bridge configuration simplifies the power stage layout, reducing stray inductance and improving overall system efficiency.

- Welding Power Supplies: Welding applications subject components to intense thermal and electrical stress. The inherent ruggedness of the 2MBI150SC-120 allows it to manage the high-current pulses required in welding, delivering consistent power for high-quality welds.

Technical Deep Dive: The NPT Advantage

At the core of the Fuji 2MBI150SC-120 is its Non-Punch-Through (NPT) IGBT silicon design. Unlike earlier Punch-Through (PT) technologies, NPT offers several distinct engineering advantages that contribute to its long-standing relevance in the industry.

First, NPT technology results in a positive temperature coefficient for the collector-emitter saturation voltage (VCE(sat)). This means that as the device heats up, its on-state voltage increases slightly. While seemingly a disadvantage, this characteristic is critical for reliable IGBT Paralleling . It ensures natural current sharing between paralleled modules without the risk of thermal runaway, where one device carries progressively more current until it fails. For high-power inverter designs that require multiple modules, this simplifies the engineering and enhances system-level reliability.

Second, the module's half-bridge, or "2-in-one," package integrates two IGBTs and two free-wheeling diodes (FWDs) into a single, low-inductance housing. This simplifies busbar design, reduces component count, and minimizes parasitic inductance that can cause voltage overshoots during high-speed switching. Engineers benefit from a more straightforward layout, improved electromagnetic compatibility (EMC), and enhanced system reliability. For engineers looking to optimize their power stage, understanding the fundamentals of IGBT structure and technology is key.

Key Parameters Overview

The following table provides a summary of the critical electrical and thermal characteristics for the Fuji 2MBI150SC-120. For a complete set of specifications, performance curves, and application notes, please refer to the official 2MBI150SC-120 datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 1200V |

| Continuous Collector Current (Ic) @ Tc=80°C | 150A |

| Collector-Emitter Saturation Voltage (Vce(sat)) @ Ic=150A, Tj=125°C | 2.7V (Max) |

| Total Power Dissipation (Pc) | 1000W |

| Operating Junction Temperature (Tj) | -40 to +150°C |

| Configuration | Dual (Half-Bridge) |

Comparative Analysis and Selection Guidance

When selecting an IGBT module, it is crucial to balance performance, cost, and design requirements. The 2MBI150SC-120 is an excellent choice for applications prioritizing robustness and proven field reliability over cutting-edge efficiency.

Compared to a more modern module like the 2MBI200NB-120-01, which utilizes newer trench-gate field-stop technology, the 2MBI150SC-120 will exhibit slightly higher conduction and switching losses. However, for applications with lower switching frequencies (typically below 10 kHz) or where cost is a primary driver, the 2MBI150SC-120 offers a compelling value proposition. Its ruggedness makes it particularly suitable for retrofitting older systems or for new designs where the operating environment is harsh and unpredictable. For new, high-frequency designs where maximizing power density and efficiency is the primary goal, a newer generation module may be more appropriate. A comprehensive understanding of IGBT failure analysis can help engineers make the most informed decision for their specific application's reliability targets.

Frequently Asked Questions (FAQ)

1. Can the 2MBI150SC-120 be used in parallel for higher current output?

Yes. One of the key strengths of its NPT IGBT technology is the positive temperature coefficient of Vce(sat). This feature promotes balanced current sharing among parallel-connected modules, making it a reliable choice for scaling power output. Proper gate drive design and symmetrical layout are still essential for optimal performance.

2. What type of gate driver is recommended for this module?

A gate driver capable of providing a +15V turn-on voltage and a negative turn-off voltage (typically -5V to -15V) is recommended to ensure fast, clean switching and to prevent spurious turn-on due to the Miller effect. A driver with desaturation protection, such as the SKHI 24 R, is also highly advised to protect the module during short-circuit events.

For detailed application support or to discuss sourcing for your next project, please contact our technical team.